drill

A drill bit and drill bit shaft technology, applied in twist drills, drilling tool accessories, drilling/drilling equipment, etc., can solve problems such as low efficiency, reduced drill bit striking efficiency, and time-consuming perforation, so as to improve work efficiency and prevent processing. Deterioration of accuracy, effect of realizing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments will be described with reference to the drawings. The same or corresponding parts are denoted by the same symbols in all the drawings, and repeated detailed explanations will be omitted.

[0038] (first embodiment)

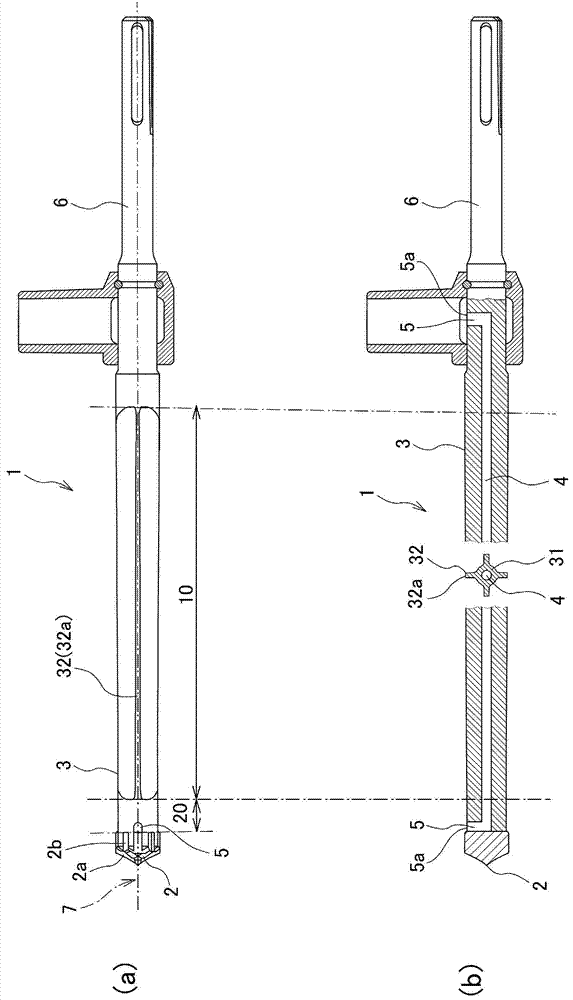

[0039] figure 1 (a) is a plan view showing a structural example of the drill of the present invention. again, figure 1 (b) is a longitudinal sectional view of the drill bit of the present invention. Also, in figure 1 In (a) and (b), the direction parallel to the central axis of the drill bit is called "axial direction", and the direction perpendicular to the central axis of the drill bit is called "radius direction". The direction of the arc at the center is called "circumferential direction". Also, for convenience of description, the "axial direction" is sometimes referred to as the front-rear direction. In this case, the direction in which the pointed portion of the drill is located is referred to as the front direction, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com