Preparation process for graphite heat conduction and dissipation patch

一种石墨导热、散热贴片的技术,应用在冷却/通风/加热改造、通过传导传热进行修饰、应用等方向,能够解决散热不均匀、胶带过热、可靠性性能差等问题,达到改善平坦性和柔韧性、提高双向拉伸性能、提高导热性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

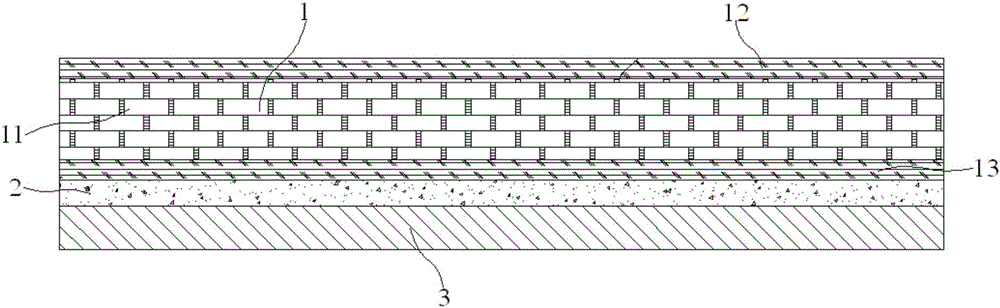

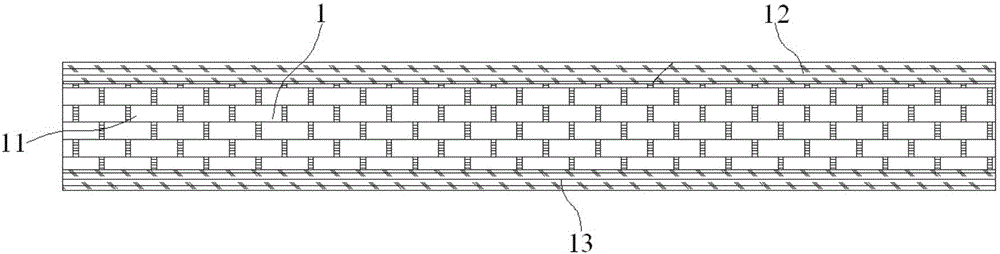

[0021] Example: A manufacturing process for graphite heat-conducting and heat-dissipating patches, the surface of the graphite heat-conducting heat-dissipating patch 1 is coated with a heat-conducting adhesive layer 2, this heat-conducting adhesive layer 2 is opposite to the graphite heat-conducting heat-dissipating patch 1 A release material layer 3 is attached to the surface; the graphite thermally conductive heat dissipation patch 1 is composed of a polyimide film 11, a first coating layer 12 and a second coating layer 13, and the first coating layer 12 is located The upper surface of the polyimide film 11;

[0022] The first coating layer is formed by a graphite modifier coated on the upper surface of the polyimide film, the graphite modifier coating is composed of the following components by weight: 22 parts of benzophenone tetraacid dianhydride , 12.5 parts of pyromellitic dianhydride, 26 parts of diaminodiphenylmethane, 22.5 parts of dimethylformamide, 9.5 parts of N-methy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com