Permanent magnet rotating coupling induction type asynchronous speed regulation system of axial magnetic field structure

A technology of axial magnetic field and speed control system, applied in the direction of permanent magnet clutch/brake, electric brake/clutch, controlling mechanical energy, etc. The problem of serious heating and high maintenance cost of frequency conversion technology can solve the problems of heating, obvious energy saving effect, and easy use and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

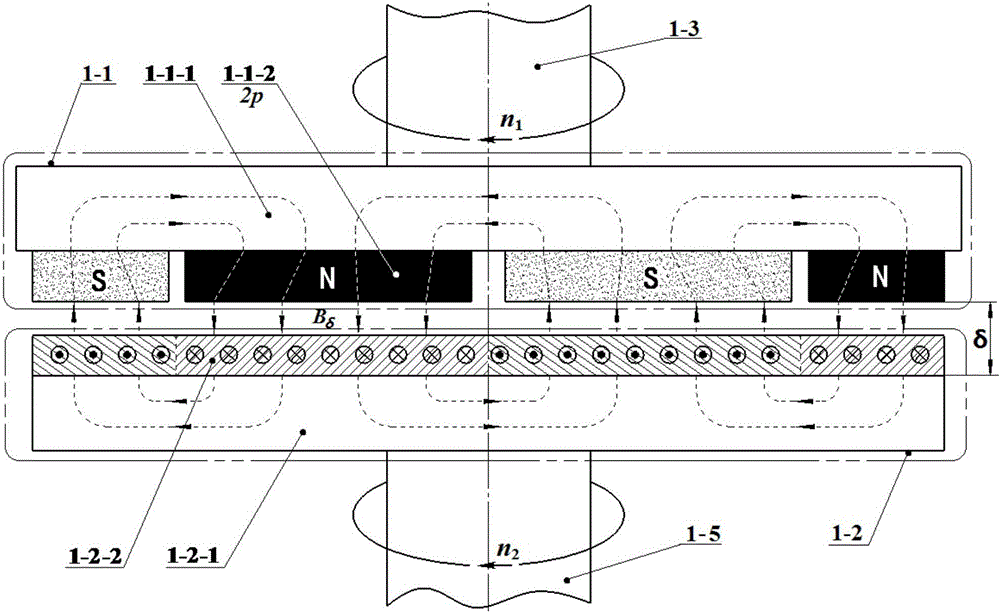

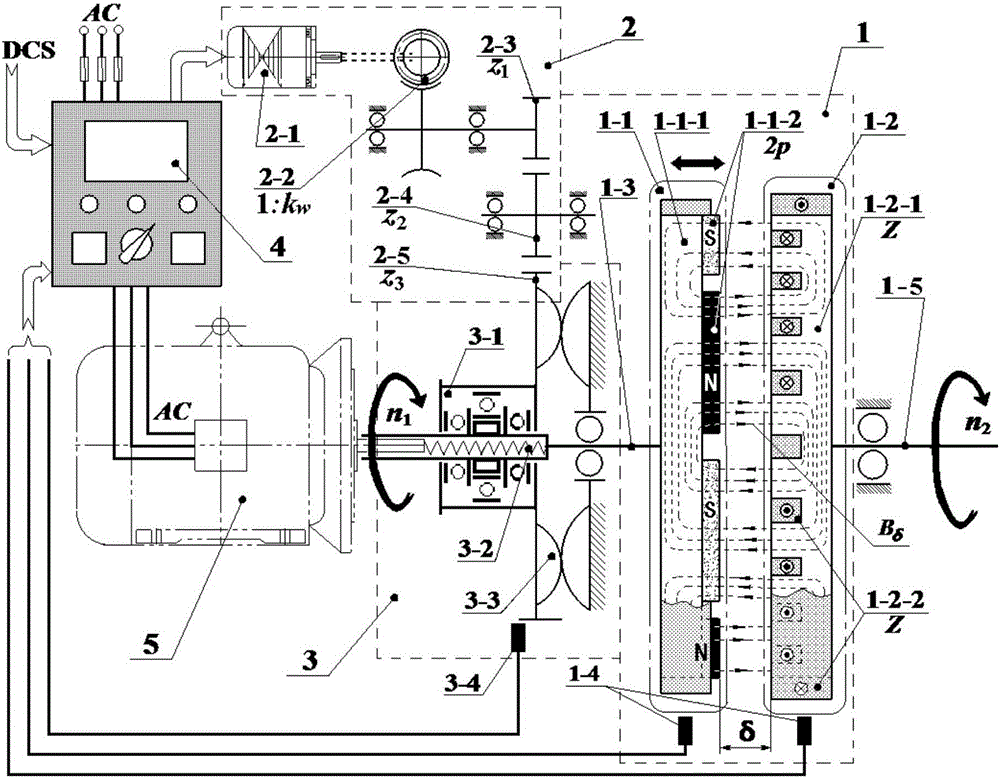

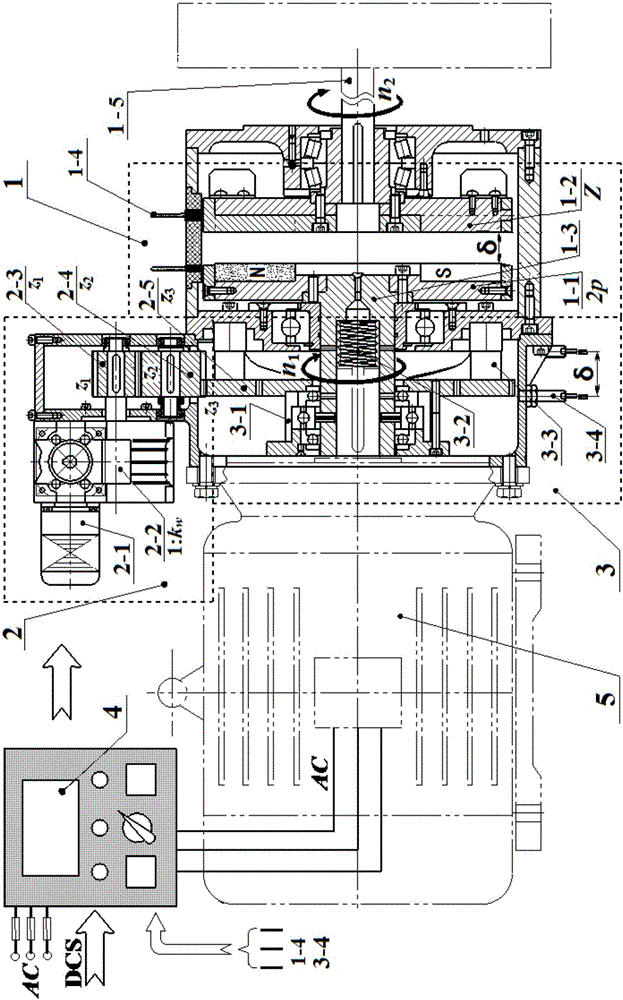

[0026] Attached below Figure 2 ~ Figure 6 And specific implementation mode The internal structural relationship characteristics of the permanent magnet rotation coupling induction type asynchronous speed regulation system of the axial magnetic field structure involved in the present invention are further described:

[0027] 1. The permanent magnet rotation coupling induction asynchronous speed regulation system with an axial magnetic field structure consists of a permanent magnet rotation induction asynchronous coupler body 1, a servo worm gear reduction mechanism 2, a cam type stroke ejection adjustment mechanism 3, and an automatic controller 4 and the AC asynchronous motor 5 for driving; the input port of the automatic controller 4 is electrically connected with the remote centralized control center DCS that issues speed regulation instructions and the three-phase AC power supply AC at the grid end, and its feedback port is connected with the permanent magnet rotation induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com