Dual-gradually-changed transitional waveguide applied to millimeter and higher frequency point coupled cavity traveling-wave tube

A transitional waveguide and coupling cavity technology, applied in the field of waveguide structure, can solve problems such as reflection, and achieve the effect of overcoming self-excited oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

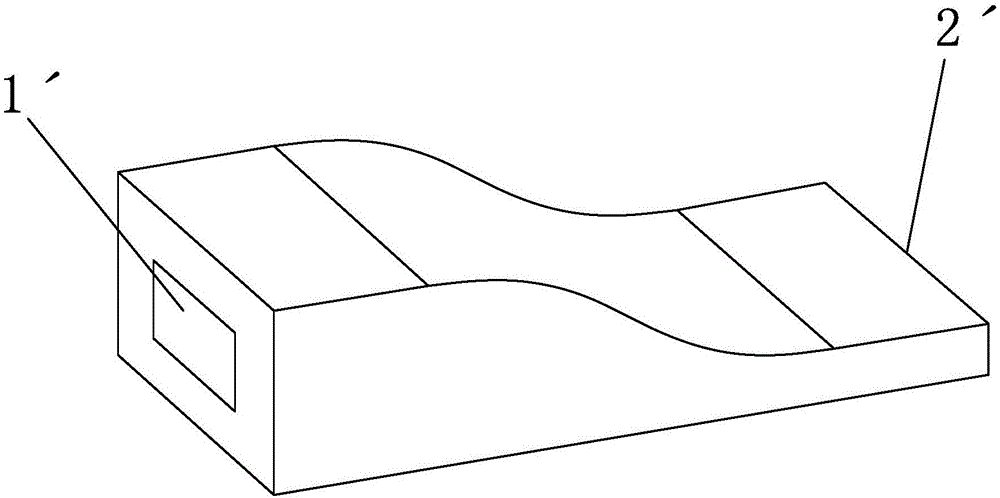

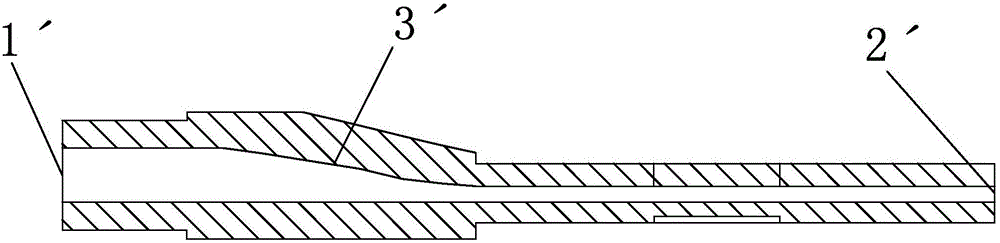

[0047] Such as Figures 6 to 10 As shown, this embodiment provides a double-tapered transition waveguide 1 used in millimeter wave and higher frequency point-coupled cavity traveling wave tubes. The transition waveguide 1 has a first port 11 and a second port 12. The first port Width L of port 11 1 greater than the width L of the second port 12 3 , the height L of the first port 11 2 greater than the height L of the second port 12 4 . The top surface 131 of the waveguide cavity 13 of the transition waveguide 1 is arranged as a gradually changing curved surface along the axial direction of the waveguide cavity 13, and the bottom surface 132 of the waveguide cavity 13 is arranged on a plane along the axial direction of the waveguide cavity 13, so The two side wall surfaces 133, 134 of the waveguide cavity 13 are arranged on symmetrical slopes along the axial direction of the waveguide cavity 13;

[0048] Further, the radial section of the waveguide cavity 13 is rectangular,...

Embodiment 2

[0051] Such as Figures 11 to 16 As shown, this embodiment provides a double-tapered transition waveguide 1 used in millimeter wave and higher frequency point-coupled cavity traveling wave tubes. The transition waveguide 1 has a first port 11 and a second port 12. The first port Width L of port 11 1 greater than the width L of the second port 12 3 , the height L of the first port 11 2 greater than the height L of the second port 12 4 .

[0052] The waveguide cavity 13 of the transitional waveguide 1 includes a first equal-diameter cavity 131 matched with the mouth end of the first port 11, a variable-diameter cavity 132, and a first equal-diameter cavity 132 matched with the mouth end of the second port 12 arranged in sequence. Two isometric chambers 133 .

[0053] The top surface 1321 of the variable diameter cavity 132 is arranged as a gradually changing curved surface along the axial direction of the waveguide cavity 13, and the bottom surface 1322 of the variable diam...

Embodiment 3

[0058] The difference between this embodiment and Embodiment 1 is that: the bottom surface of the waveguide cavity is arranged as a gradually changing curved surface along the axial direction of the waveguide cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com