GaN-based light emitting diode (LED) epitaxial structure with V-pit multi-quantum well multi-wavelength and fabrication method thereof

A multi-quantum well and epitaxial structure technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem that the light source does not understand the harm of blue light, and achieve the effect of no blue light harm, simple driving circuit, and free adjustment of color rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

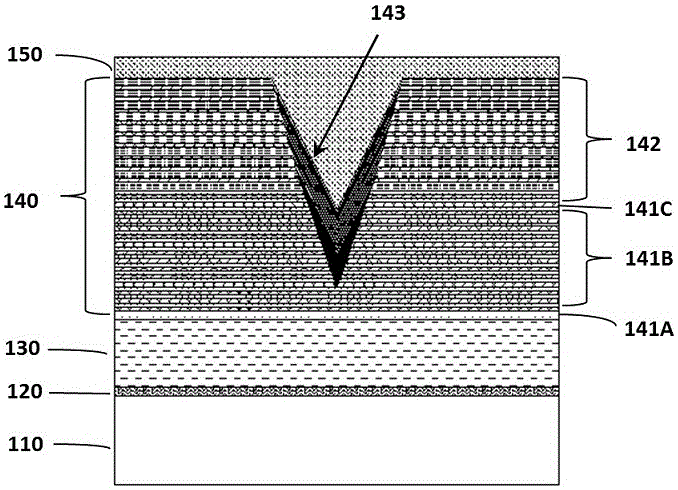

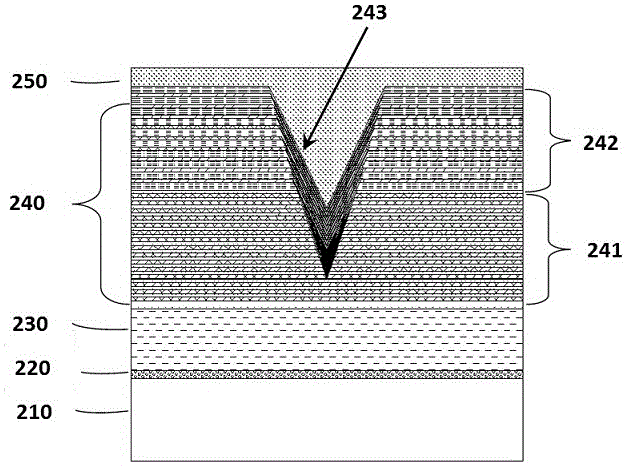

[0039] as shown in the picture 2 shown, according to the example 1 the belt V Pit Multiple Quantum Well Multiple Wavelength GaN base led The epitaxial structure includes: substrate 210 , buffer layer set on the substrate 220 , set on the buffer layern type layer 230 , set at n type layer 230 active layer on 240 and set in the active layer 240 Up P type layer 250 。

[0040] In this example, in n type layer 230 Active layer set on 240 including multiple layers 241 , Lighting unit 242 and V pit 243 。

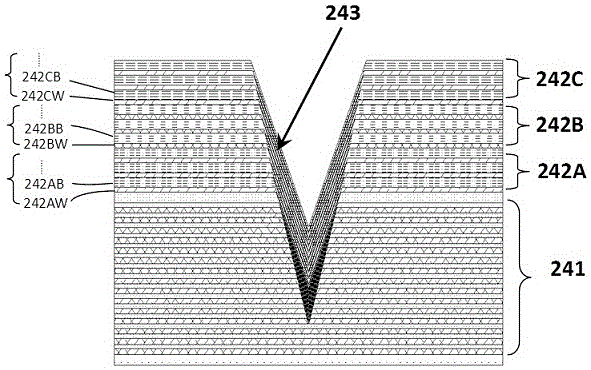

[0041] In this embodiment, as shown in 3 As shown, the light emitting unit 242 set in a multi-layer structure 241 on, including 3 luminous area 242A 、 242B and 242C , which in turn is set in a multi-layer structure 241 blue multiple quantum well light-emitting region 242A , set in the blue light multi-quantum well light-emitting area 242A Green Multiple Quantum Well Light Emitting Region 242B , set in the green...

Embodiment 2

[0045] as shown in the picture 4 shown, according to the example 2 with V Pit Multiple Quantum Well Multiple Wavelength GaN base led The epitaxial structure includes: substrate 310 , set on the substrate 310 buffer layer on 320 , set in the buffer layer 320 Up n type layer 330 , set at n type layer 330 active layer on 340 and set in the active layer 340 Up P type layer 350 。

[0046] In this example, in n type layer 330 Active layer set on 340 including multiple layers 341 , Lighting unit 342 and V pit 343 。

[0047] In this embodiment, as shown in 5 As shown, the light emitting unit 342 set in a multi-layer structure 341 on, including 4 luminous area 342A 、 342B 、 342C and 342D , which in turn is set in a multi-layer structure 341 blue multiple quantum well light-emitting region 342A , set in the blue light multi-quantum well light-emitting area 342A multi-subwell light-emitting region 342B , set in the c...

Embodiment 3

[0051] as shown in the picture 6 shown, according to the example 3 with V Pit Multiple Quantum Well Multiple Wavelength GaN base led The epitaxial structure includes: substrate 410 , buffer layer set on the substrate 420 , set on the buffer layer n type layer 430 , set at n type layer 430 active layer on 440 and set in the active layer 440 Up P type layer 450 。

[0052] In this example, in n type layer set on the active layer 440 including multiple layers 441 , Lighting unit 442 and V pit 443 。

[0053] In this embodiment, as shown in 7 As shown, the light emitting unit 442 set in a multi-layer structure 441 on, including 5 luminous area 442A 、 442B 、 442C 、 442D and 442E , which in turn is set in a multi-layer structure 441 blue multiple quantum well light-emitting region 442A , set in the blue light multi-quantum well light-emitting area 442A Cyan multiple quantum well light-emitting region 442B , set in the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com