A kind of elastic conductive film material and preparation method thereof

A technology of elastic conductive and film materials, applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., can solve the problems of poor flexibility of conductive film, complicated preparation process, resistance to bending and compression, etc., and achieve electrical performance Stable, good conductivity, not easy to wear and leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

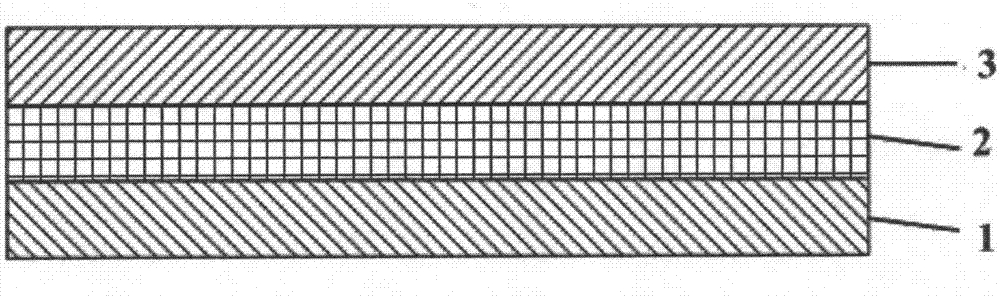

[0035] A preparation method of an ultra-thin elastic conductive film material, the specific steps are:

[0036] The first step: select the elastic film 1 (PDMS film) as the elastic attachment matrix, apply a certain tension to both ends of it, stretch it to 40% of the elongation at break of the elastic film and fix it, and coat the surface of the PDMS film with a A layer of liquid elastic adhesive (using PDMS adhesive) to form an adhesive layer with a thickness of about 0.2mm;

[0037] The PDMS membrane is a square PDMS membrane with a size of 30×30cm 2 , the thickness is 0.5mm. The PDMS film was obtained by coating film method using PDMS resin (Dow Corning DC184).

[0038] The PDMS adhesive adopts SYLGARD184 of Dow Corning Company, which is obtained by mixing the basic components (PDMS liquid, viscosity 5.2 Pa-sec) and curing agent (viscosity 3.5 Pa-sec) in a weight ratio of 10:1.

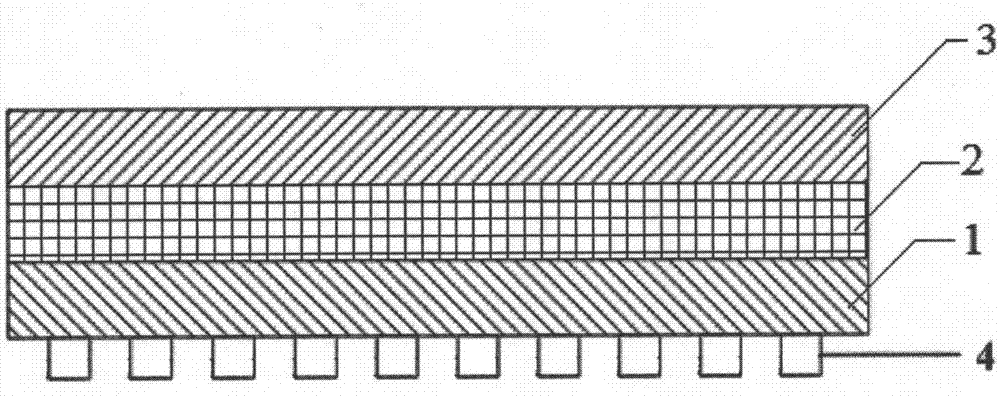

[0039] The second step: using silver glue to bond the copper wire electrode and the carbon ...

Embodiment 2

[0046] A preparation method of an elastic conductive film, the specific steps are:

[0047] The first step: select the elastic film 1 (PDMS film) as the elastic attachment matrix, apply a certain tension to both ends of it, stretch it to 50% of the elongation at break of the elastic film and fix it, and coat the surface of the PDMS film with a A layer of liquid elastic adhesive (using PDMS adhesive) to form an adhesive layer with a thickness of about 0.2mm;

[0048] The PDMS membrane is a square PDMS membrane with a size of 30×30cm 2 , the thickness is 0.5mm. The PDMS film was obtained by coating film method using PDMS resin (Dow Corning DC184).

[0049] The PDMS adhesive adopts SYLGARD184 of Dow Corning Company, which is obtained by mixing the basic components (PDMS liquid, viscosity 5.2 Pa-sec) and curing agent (viscosity 3.5 Pa-sec) in a weight ratio of 10:1.

[0050] The second step: using silver glue to bond the copper wire electrode and the carbon nanotube film to obt...

Embodiment 3

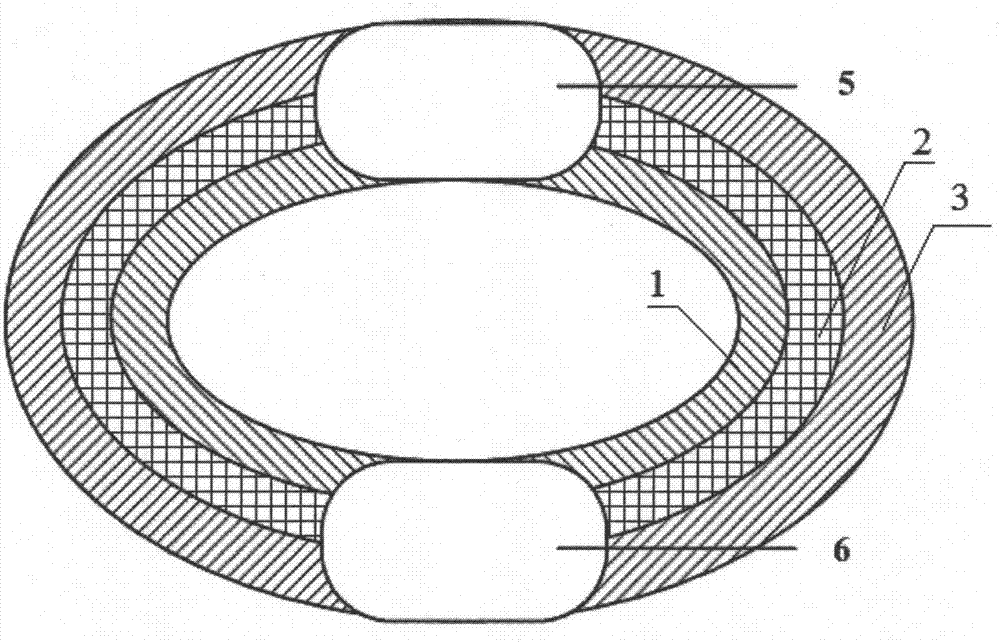

[0058] A preparation method of an elastic conductive bracelet, the specific steps are:

[0059] The first step: select the elastic film 1 (PDMS film) as the elastic attachment matrix, apply a certain tension to both ends of it, stretch it to 50% of the elongation at break of the elastic film and fix it, and coat the surface of the PDMS film with a A layer of liquid elastic adhesive (using PDMS adhesive) to form an adhesive layer with a thickness of about 0.2mm;

[0060] The PDMS membrane is a rectangular PDMS membrane with a size of 1.5*16cm 2 , the thickness is 0.4mm. The PDMS film was obtained by coating film method using PDMS resin (Dow Corning DC184).

[0061] The PDMS adhesive adopts SYLGARD184 of Dow Corning Company, which is obtained by mixing the basic components (PDMS liquid, viscosity 5.2 Pa-sec) and curing agent (viscosity 3.5 Pa-sec) in a weight ratio of 10:1.

[0062] The second step: using silver glue to bond the copper wire electrode and the carbon nanotube f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com