Mesh electrode diamond X-ray measuring device

A technology of mesh electrodes and measuring devices, which is applied in the field of X-ray radiation measurement, can solve the problems of low X-ray measurement, inability to guarantee coaxial output, and difficult calibration, so as to reduce the distortion of measurement signals and facilitate sensitivity calibration and measurement applications , easy to aim effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

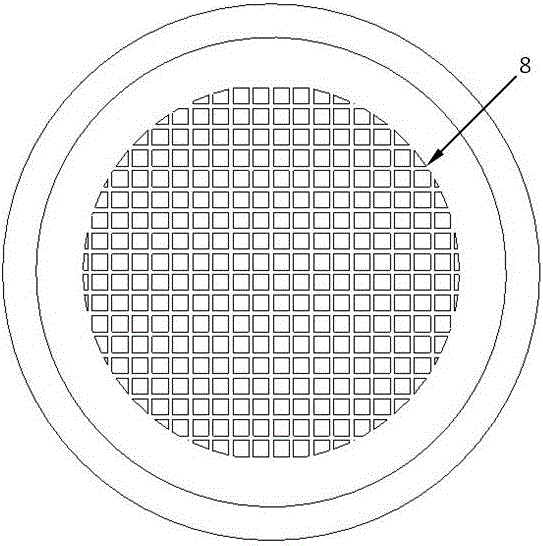

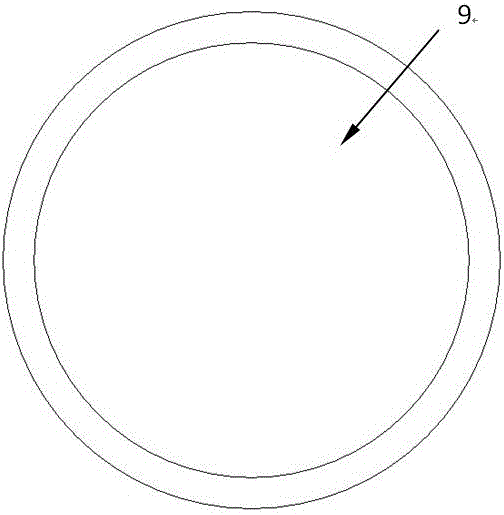

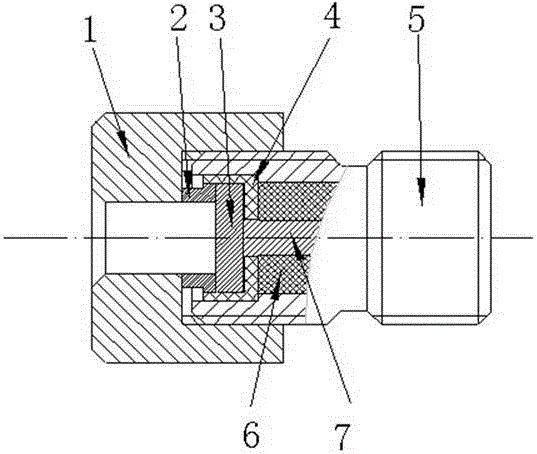

[0020] figure 1 It is the structural representation of the mesh electrode diamond X-ray measuring device of the present invention, Figure 2a For the diamond top view in the present invention, Figure 2b It is a bottom view of diamond in the present invention. exist figure 1 , Figure 2a , Figure 2b Among them, the mesh electrode diamond X-ray measuring device of the present invention includes a connecting ring 1, a gasket 2, a diamond 3, an insulating ring 4, a casing 5, an insulating layer 6, and a core needle 7, and the gasket 2 is a ring-shaped metal piece, the diamond 3 is cylindrical. The connection relationship is that one end surface of the diamond 3 is coated with a mesh electrode 8 and the other end surface is coated with a disc electrode 9 . The connecting ring 1 is fixedly socketed on the front end of the casing 5 through threads, and a gasket 2, a diamond 3, an insulating ring 4, an insulating layer 6, a gasket 2, a diamond 3, and an insulating layer are se...

Embodiment 2

[0031] The structure of this embodiment is the same as that of Embodiment 1. The difference is that the material of the gasket 2 is stainless steel, the diamond 3 is CVD diamond with a diameter of 5 mm and a thickness of 0.5 mm, and the disc electrode 9 is gold with a diameter of 4.5 mm and a thickness of 0.5 μm. The end connector of the shell 5 is N-type; the outer diameter of the mesh electrode 8 is 4.5 mm, the diameter of the central mesh is 3.6 mm, the duty ratio of the central mesh is 20%, and the material is 1 μm thick gold.

Embodiment 3

[0033] The structure of this embodiment is the same as that of Embodiment 1, except that the material of the gasket 2 is aluminum; the terminal connector of the shell 5 is BNC type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com