Seepage testing apparatus and method for rock with single fracture

A test device and rock technology, applied in the direction of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of inability to truly simulate the seepage process of natural fractured rock mass, small pressure adjustment range, and uncontrollable pressure and other problems, to achieve the effect of increasing the range of water pressure that can be applied, ensuring accuracy, and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

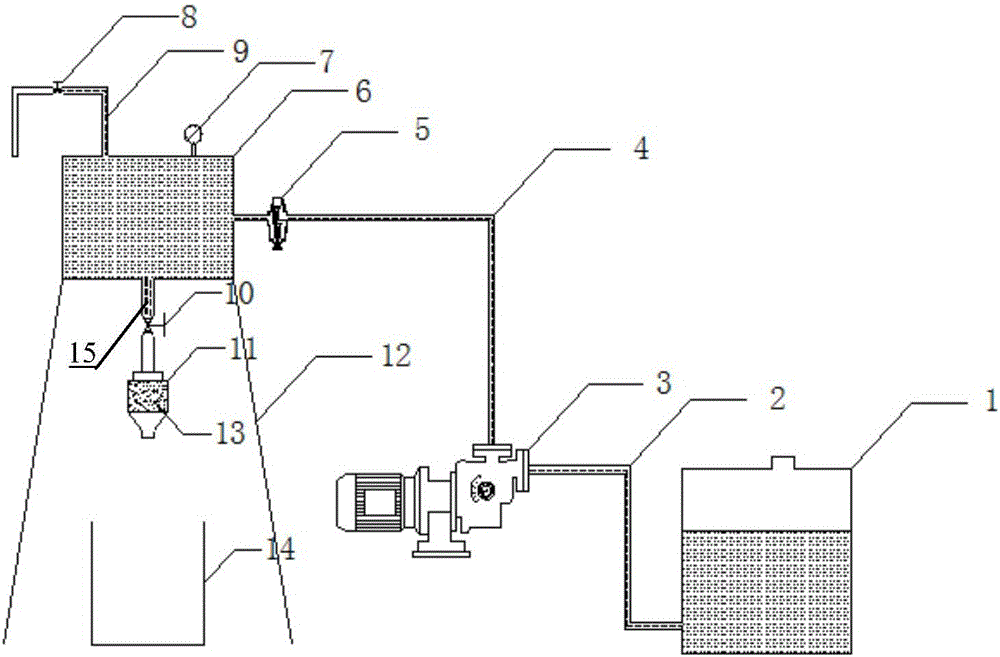

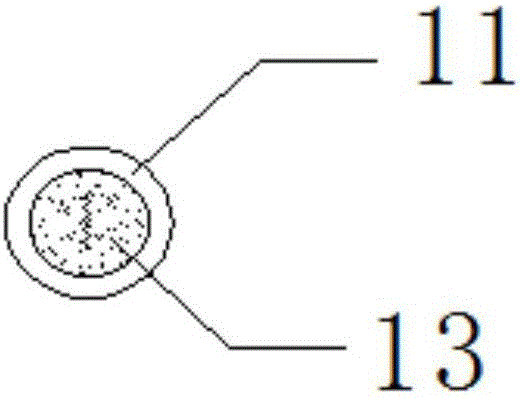

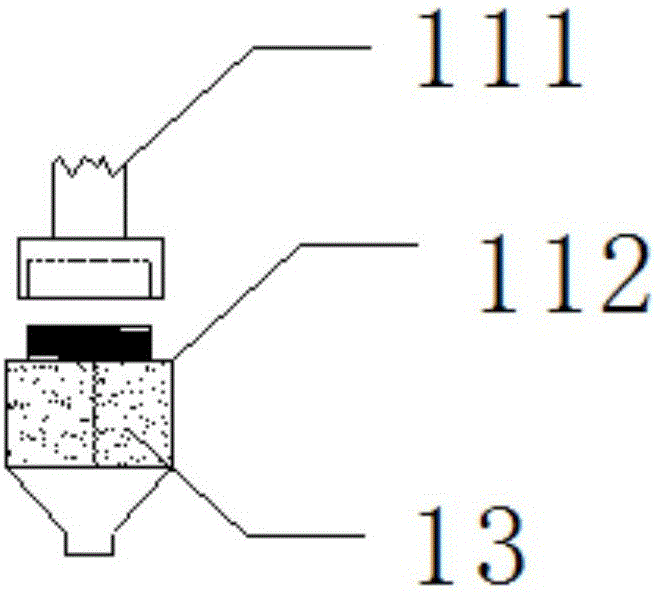

[0036] In the embodiment of the present invention, such as figure 1 As shown, the single fracture rock seepage test device includes a water tank 1, a frequency conversion self-priming booster pump 3, a water storage tank 6, a digital display water pressure gauge 7, a detachable test piece loading sealed cavity 11, a water collector 14 and four The tripod 12, wherein, the water tank 1 is connected to the frequency conversion self-priming booster pump 3 through the conduit 2, and the frequency conversion self-priming booster pump 3 is connected to the water storage tank 6 through the conduit 4, and the water storage tank 6 is arranged on the upper end of the tripod 12 and the water storage tank 6. The lower end is connected to the detachable test piece loading sealed cavity 11 through a conduit 15, the water collector 14 is placed at the lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com