An operation method for an optimal operation device of a double back pressure condenser

A technology to optimize operation and operation method, applied in steam/steam condenser, lighting and heating equipment, etc., can solve problems such as increased back pressure of low back pressure side condenser, reduced tightness, increased heat rate of steam turbine, etc. , to achieve the effect of reducing the heat rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

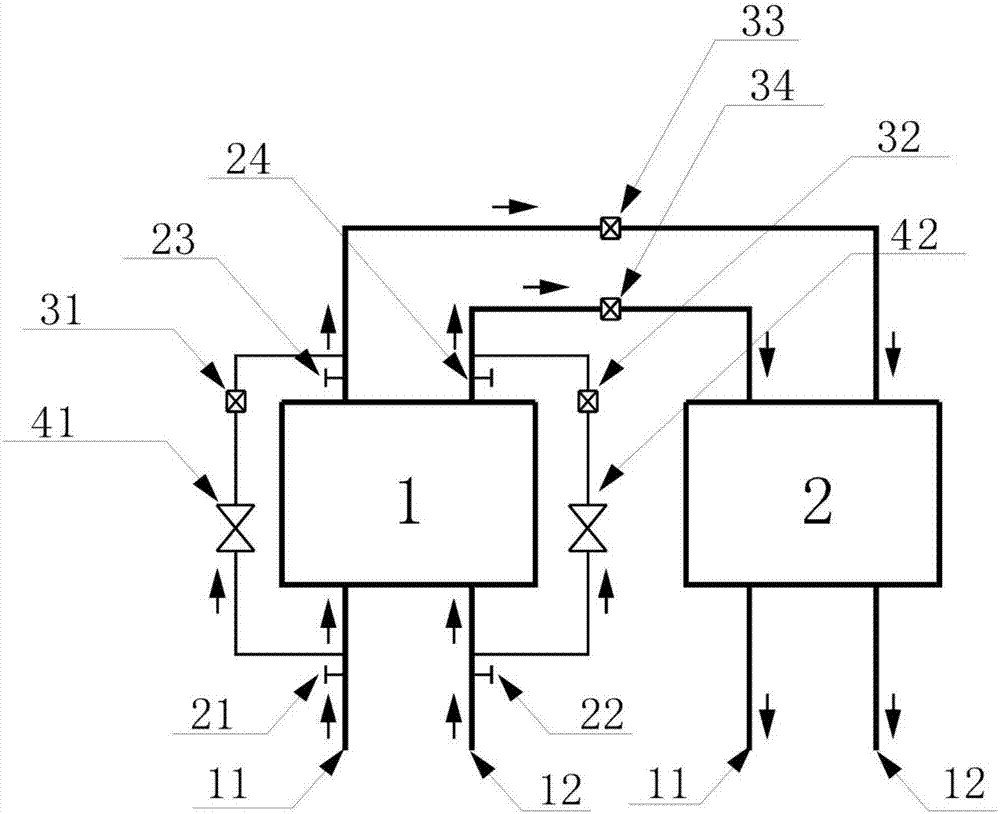

[0040] An optimal operation device for double back pressure condensers, including a high back pressure condenser 2, a low back pressure condenser 1 and a circulating water pipeline, the circulating water pipeline is divided into a first circulating water pipeline 11 and a second circulating water pipeline 12. Both the first circulating water pipeline 11 and the second circulating water pipeline 12 flow from the low back pressure condenser 1 to the high back pressure condenser 2, which is characterized in that a first bypass is set on the first circulating water road, The first bypass is connected across the two ends of the low back pressure condenser 1, a second bypass is provided on the second circulating waterway, and the second bypass is also connected across the two ends of the low back pressure condenser 1, A second control valve 41 is arranged on the first bypass, and a second control valve 42 is arranged on the second bypass. When the unit is running and the vacuum of t...

Embodiment 2

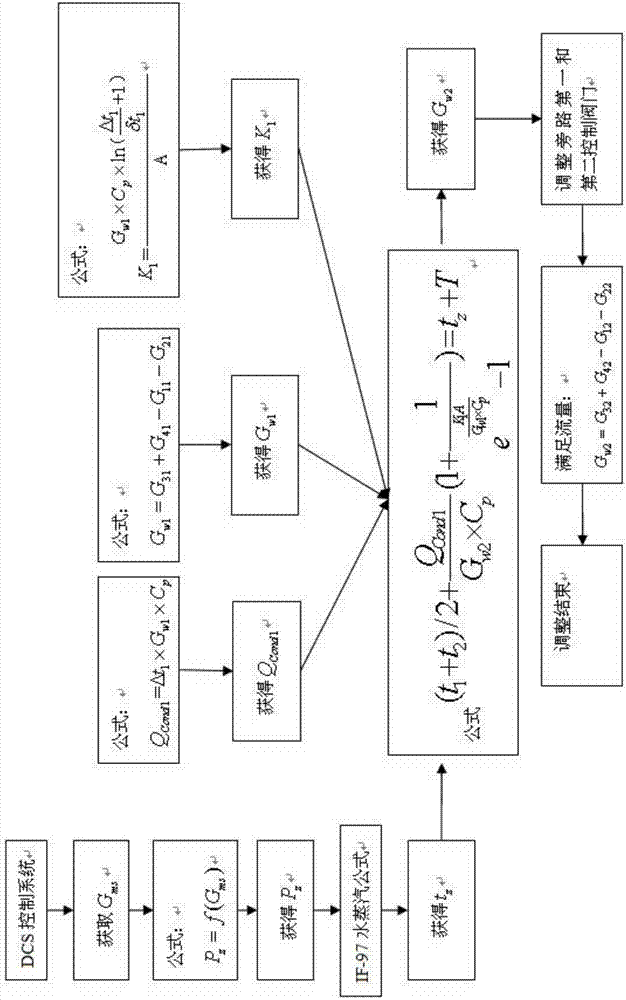

[0047] An operation method for the above-mentioned double back pressure condenser optimal operation device, characterized in that it comprises the following steps:

[0048] Step 1. Calculation of steam turbine blocking back pressure value P z ,

[0049] P z =f(G ms )------Formula 1)

[0050] where G ms is the main steam flow rate of the steam turbine, the unit is kg / s, obtained by the DCS system of the steam turbine;

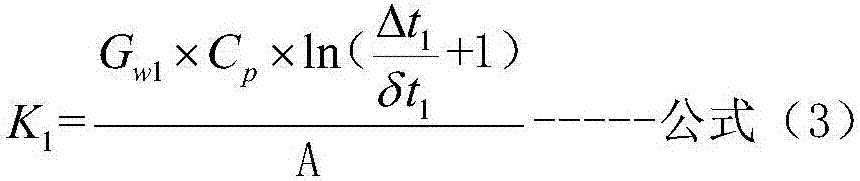

[0051] Step 2. Calculating the blocked exhaust steam temperature t of the steam turbine z , according to the turbine blocking back pressure value P calculated in step 1 z , according to the IF-97 water vapor formula, the corresponding saturated steam temperature is the steam turbine blocked exhaust temperature t z ; The main steam flow G of the steam turbine obtained by the unit DCS control system ms , calculate the corresponding blocking back pressure value according to the formula (1), and calculate the corresponding saturated steam temperature t accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com