Water cooling cantilever roller way for steel billet heating furnace

A cantilever roller table and billet heating technology, which is applied in the field of water-cooled cantilever roller table, can solve the problem of high annual consumption of the cantilever roller table, achieve considerable economic benefits, reduce production costs, and enhance the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

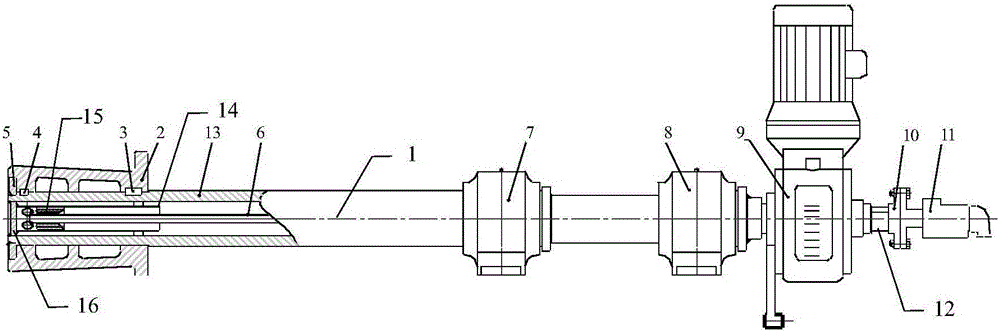

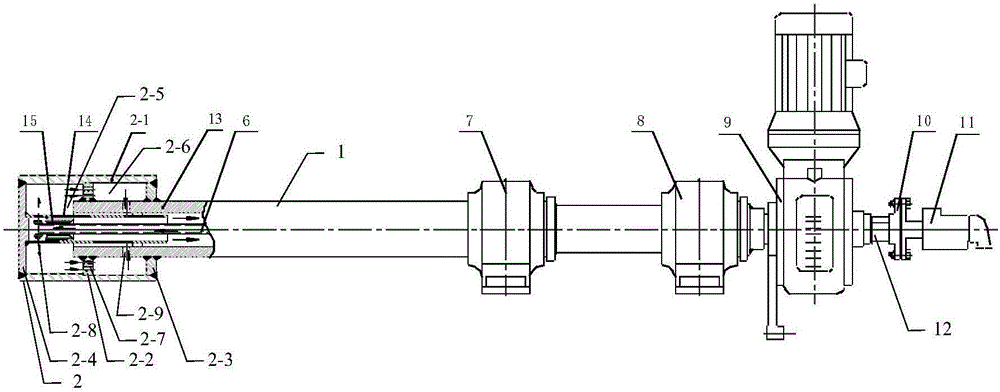

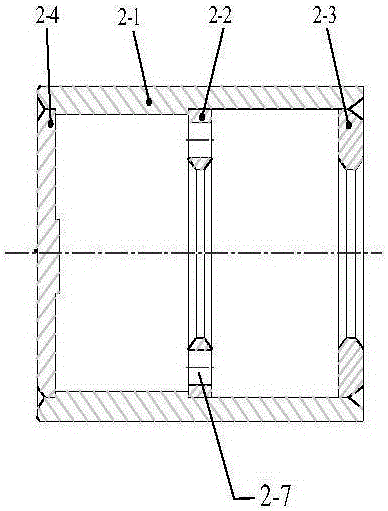

[0028] Such as figure 2 and image 3 As shown, a water-cooled cantilever roller table for a billet heating furnace, the roller table includes a roller shaft 1 and a roller 2, and the roller shaft 1 includes a water inlet pipe 6, a hollow shaft 13, an inner pipe 14 and a water diversion block 15 ; The roller 2 includes a roller body 2-1, an inner ring 2-2, a fixed plate 2-3 and an end cap 2-4, and the roller body 2-1 is hollow cylindrical, and one end is closed by an end cap 2-4 , the other end is closed by a fixed plate 2-3, and an inner ring 2-2 is arranged in the radial direction of the roller body 2-1 to divide the inner cavity of the roller body 2-1 into a front cavity 2-5 and a rear cavity 2-6, and the inner ring 2- 8 communication holes 2-7 are arranged on 2, which are used to communicate with the front cavity 2-5 and the rear cavity 2-6;

[0029] The hollow shaft 13 passes through the fixed plate 2-3 and the inner ring 2-2, and is fixed between the three;

[0030] O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com