Backpressure-adjusting pilot operated safety valve

A pilot-operated safety valve and back pressure adjustment technology, which is applied in the field of pressure vessels or pressure pipelines, and pilot-operated safety valves, can solve the problems of easy backflow of medium and poor reverse sealing performance, so as to achieve good anti-backflow and prevent medium backflow , Reliable effect of reverse sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

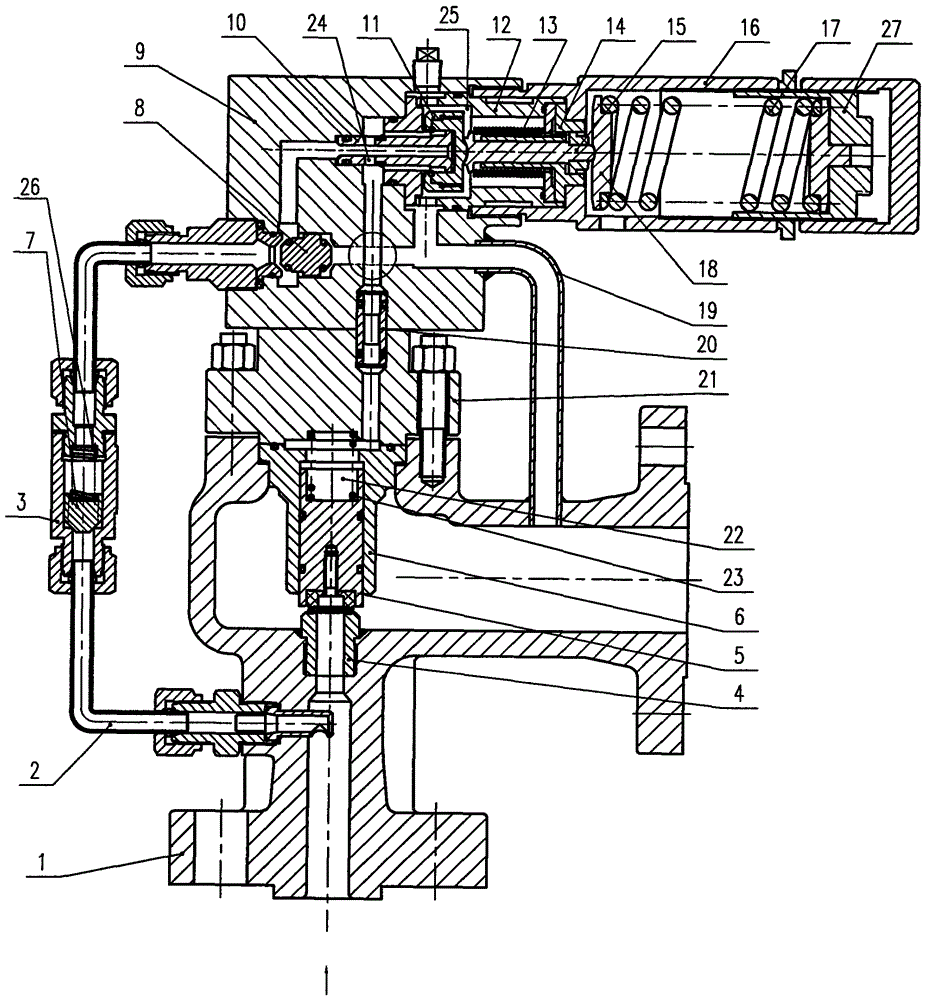

[0011] Such as figure 1 The shown back pressure regulating pilot safety valve includes a main valve and a pilot valve. The main valve includes a main valve body 1, a main valve seat 4, a main valve disc 5, and a main valve cover 21. The main valve seat 4 is installed on the main valve body 1. Between the inlet cavity and the discharge cavity, a guide sleeve 6 is installed between the main valve body 1 and the main valve cover 21. The outer circular surface of the main valve disc 5 is in dynamic sealing cooperation with the inner cavity wall of the guide sleeve 6. The back side of the main valve disc 5, A back pressure cavity 22 is formed between the inner cavity wall of the guide sleeve 6 and the lower end surface of the main valve cover 21, and a spring 23 is installed between the back of the main valve flap 5 in the back pressure cavity 22 and the lower end surface of the main valve cover 21; Valve body 9, pilot valve seat 10, pilot valve disc 11, pilot valve cover 16 and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com