Glass-fiber air filter paper containing carbon nanometer materials and preparing method thereof

A technology of air filter paper and carbon nanomaterials, applied in the field of materials, can solve the problems of carbon nanomaterials easy to fall off and powder, inconvenient production and use process, and harsh method conditions, so as to ensure antibacterial efficiency and durability, and not easy to fall off The effect of powder dropping and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

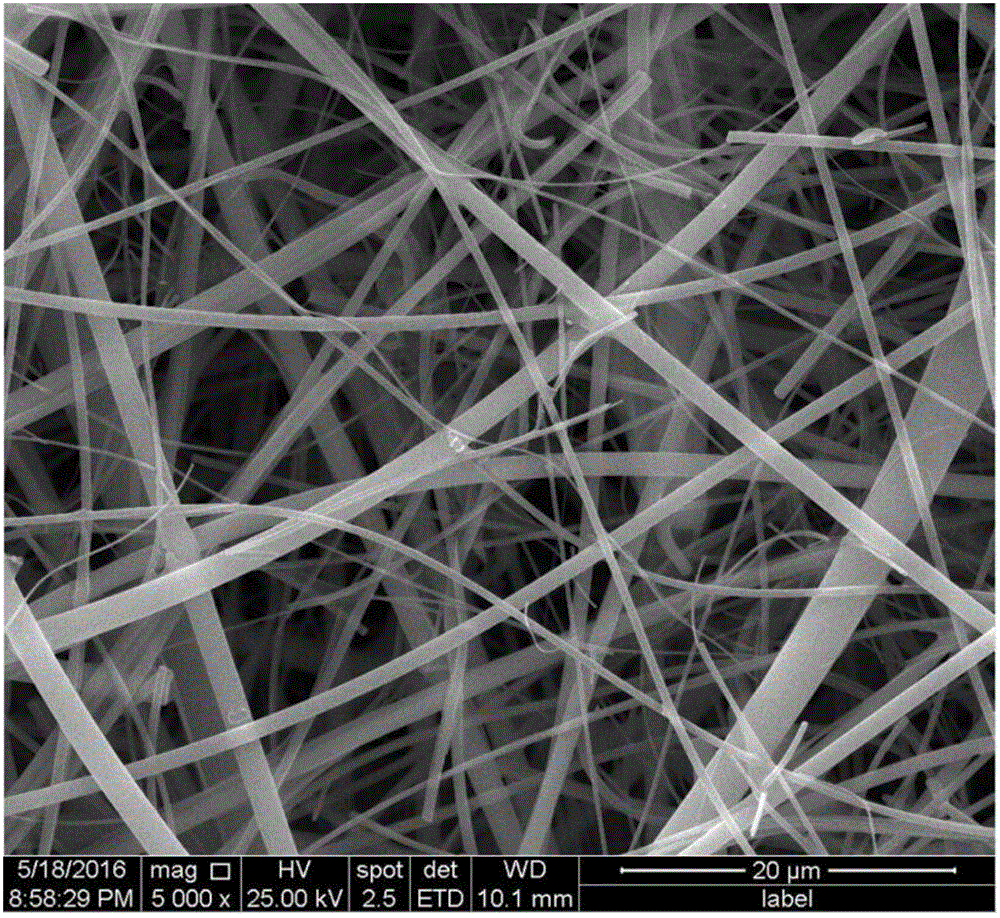

Image

Examples

Embodiment 1

[0033] A preparation method of glass fiber air filter paper containing carbon nanomaterials, comprising the following steps:

[0034] (1) Add carbon nanotubes with a diameter of 50 to 80 nm into an aqueous solution of sodium lauryl sulfate with a concentration of 0.5 g / L, and ultrasonically disperse them at 1000 W for 5 minutes, so that the mass fraction of carbon nanotubes is 0.2%. carbon nanomaterial dispersion;

[0035] (2) After mixing glass fibers with a diameter of 6.5 μm and glass wool fibers with a diameter of 0.1 to 2 μm at a mass ratio of 1:4, add water and acid to adjust the pH value to 3, and disperse at a speed of 2000 rpm for 10 minutes Then add the polyoxyethylene aqueous solution that is 1g / L the polyoxyethylene aqueous solution that is configured into by the polyoxyethylene that molecular weight is 6,000,000 with water, is configured into the glass fiber material dispersion that the mass fraction summation of glass fiber and glass wool fiber is 0.05%, wherein ...

Embodiment 2

[0039] A preparation method of glass fiber air filter paper containing carbon nanomaterials, comprising the following steps:

[0040] (1) Add carbon nanotubes with a diameter of 1 to 20 nm into an aqueous solution of sodium alkane sulfonate with a concentration of 1 g / L, and ultrasonically disperse them at 1000 W for 5 minutes to form a carbon nanotube with a mass fraction of 0.05%. Carbon nanomaterial dispersion;

[0041](2) After mixing glass fibers with a diameter of 15 μm and glass wool fibers with a diameter of 0.05 to 0.5 μm at a mass ratio of 1:1, add water and acid to adjust the pH value to 3, and disperse at a speed of 2000 rpm for 10 minutes Then add the polyacrylamide aqueous solution that is 1g / L by the polyacrylamide that molecular weight is 100,000 to add water to configure, and the mass fraction summation that is configured into glass fiber and glass wool fiber is the glass fiber material dispersion liquid of 0.05%, wherein , the addition of polyacrylamide aque...

Embodiment 3

[0045] A preparation method of glass fiber air filter paper containing carbon nanomaterials, comprising the following steps:

[0046] (1) Add carbon nanofibers with a diameter of 80 to 100nm into an aqueous solution of sodium dodecylbenzenesulfonate at a concentration of 0.1g / L, and disperse them ultrasonically for 5 minutes at 1000W to configure the mass fraction of carbon nanofibers 0.5% carbon nanomaterial dispersion;

[0047] (2) After mixing glass fibers with a diameter of 25 μm and glass wool fibers with a diameter of 0.5 to 2 μm at a mass ratio of 1:2, add water and acid to adjust the pH value to 3, and decompose and disperse at a speed of 2000 rpm for 10 minutes; then add A polyacrylamide aqueous solution with a concentration of 1 g / L prepared by adding water to a polyacrylamide with a molecular weight of 10 million is prepared as a glass fiber material dispersion with a total mass fraction of glass fibers and glass wool fibers of 0.01%, wherein polypropylene The addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com