Glass fiber zero tensioner

A tensioner and installation base technology, applied in the field of warping machines, can solve the problems of friction between the yarn and the tensioner, and the yarn tension cannot be moderately kept consistent, and achieve the effect of keeping the speed consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

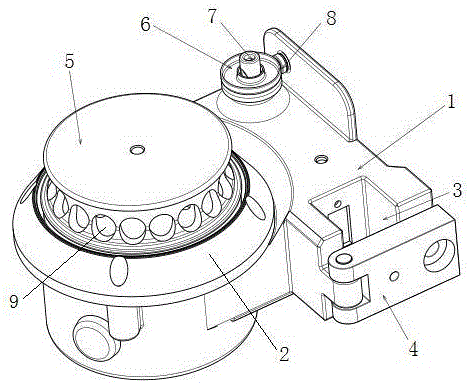

[0010] Such as figure 1 It is a structural schematic diagram of the present invention, a glass fiber zero-degree tensioner, including a mounting base 1, and the adjacent sides of the mounting base 1 are provided with a mounting groove 2 and a fixed cavity 3, and the mounting groove 2 is provided with a motor , the motor is provided with a rotating wheel 5, and the rotating wheel 5 is evenly distributed with holes 9 around the circumference, a fixed block 4 is provided on one side of the fixed cavity 3, and a yarn pressing sheet 6 and a yarn guide porcelain eye 7 are provided on the installation base 1. One side of the pressing sheet 6 is provided with an introduction porcelain eye 8, and the rotating wheel 5 is made of aluminum and hard chrome-plated on the surface.

[0011] The fiberglass zero-degree yarn tensioner is a yarn tensioner that can handle the yarn gently and run quietly. Its working principle is not to generate tension by rubbing the yarn, but to adjust the yarn t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com