Humulus lupulus addition device and method

A technology of adding devices and hops, which is applied in the field of beer brewing, can solve the problems of inability to achieve automation and unattended, and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

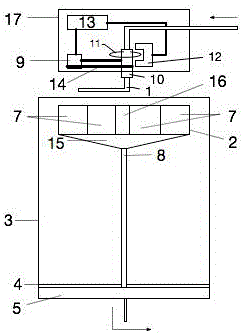

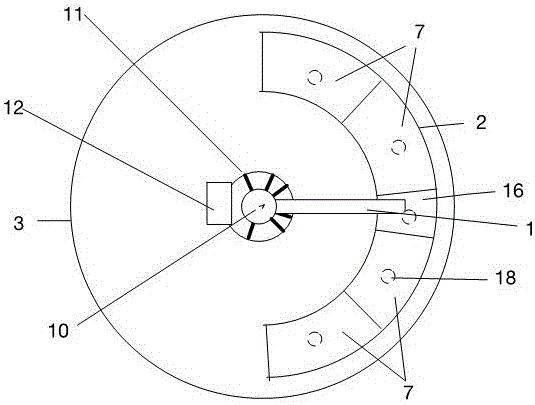

[0016] Such as Figure 1 to Figure 2 As shown, the present invention provides a hop adding device, comprising a liquid outlet pipe 1, a hop storage container 2, a malt storage container 3, a driving mechanism 17 and a wheat dregs filter part 4, the liquid outlet pipe 1, the hop storage The container 2 and the malt storage container 3 are arranged sequentially from top to bottom; the malt filter part 4 is arranged in the malt storage container 3 and divides the malt storage container 3 into an upper malt storage space and a lower malt storage space. Filtration space 5; the hop storage container 2 includes a waterway through cavity 16 and a hop storage cavity 7, and the bottom of the waterway through cavity 16 and the bottom of the hop storage cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com