Automatic lead removing press

A technology of automatic lead discharging and pressing machine, applied in detonator, offensive equipment and other directions, can solve the problems of inability to guarantee safety, low efficiency, etc., and achieve the effect of improving product quality, reducing production cost, and loading and pressing lead safely and reliably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing by embodiment:

[0017] preferred embodiment

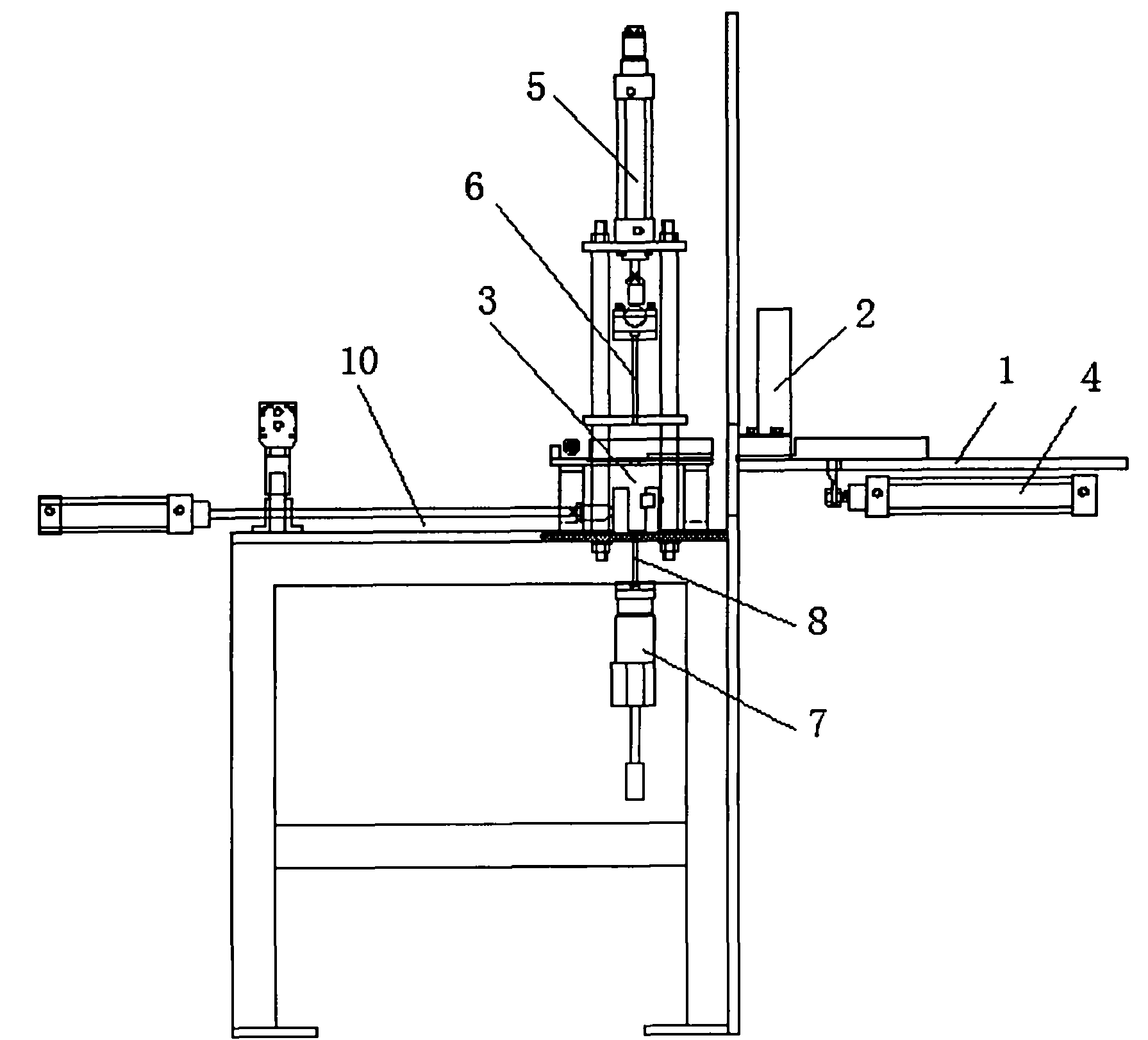

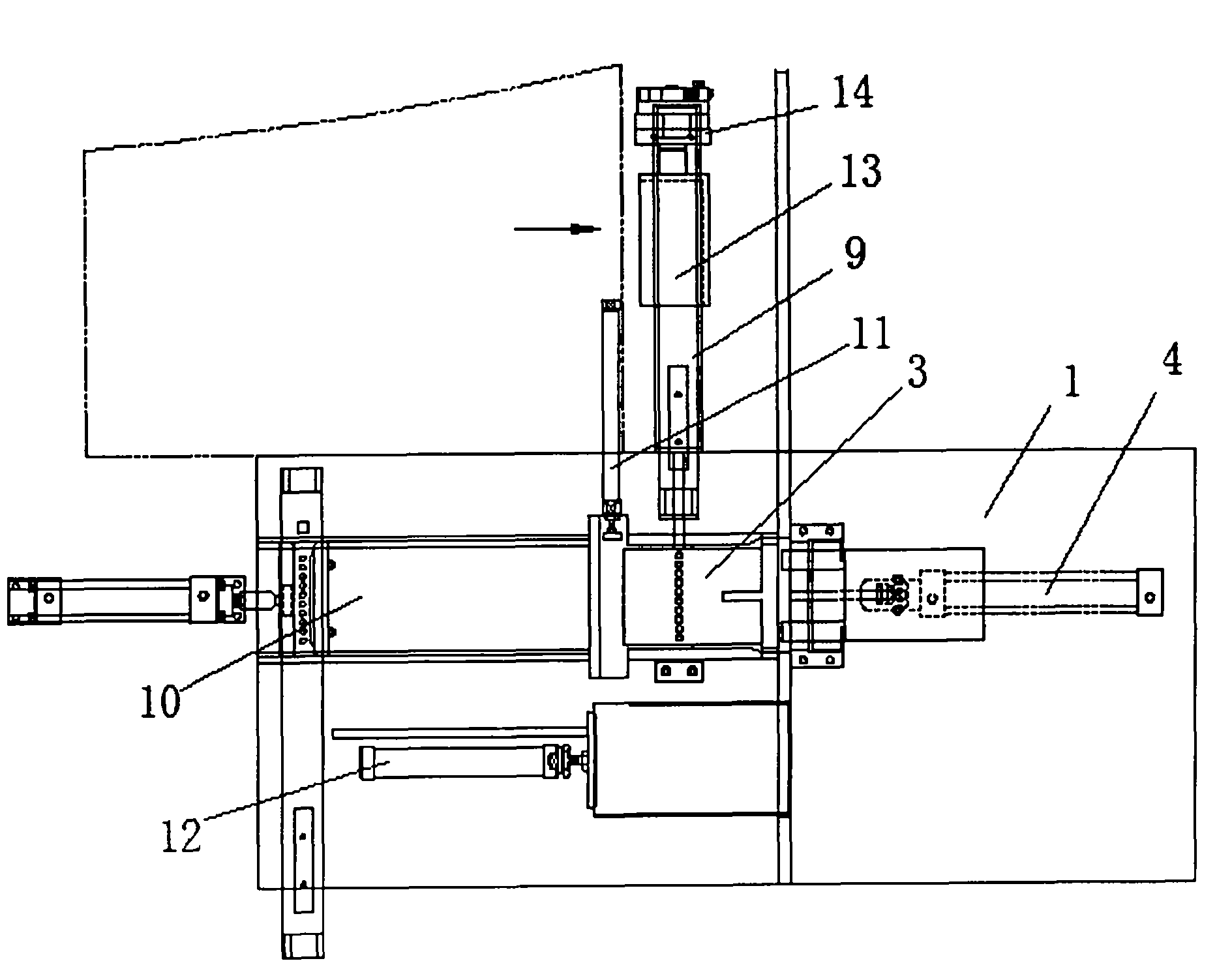

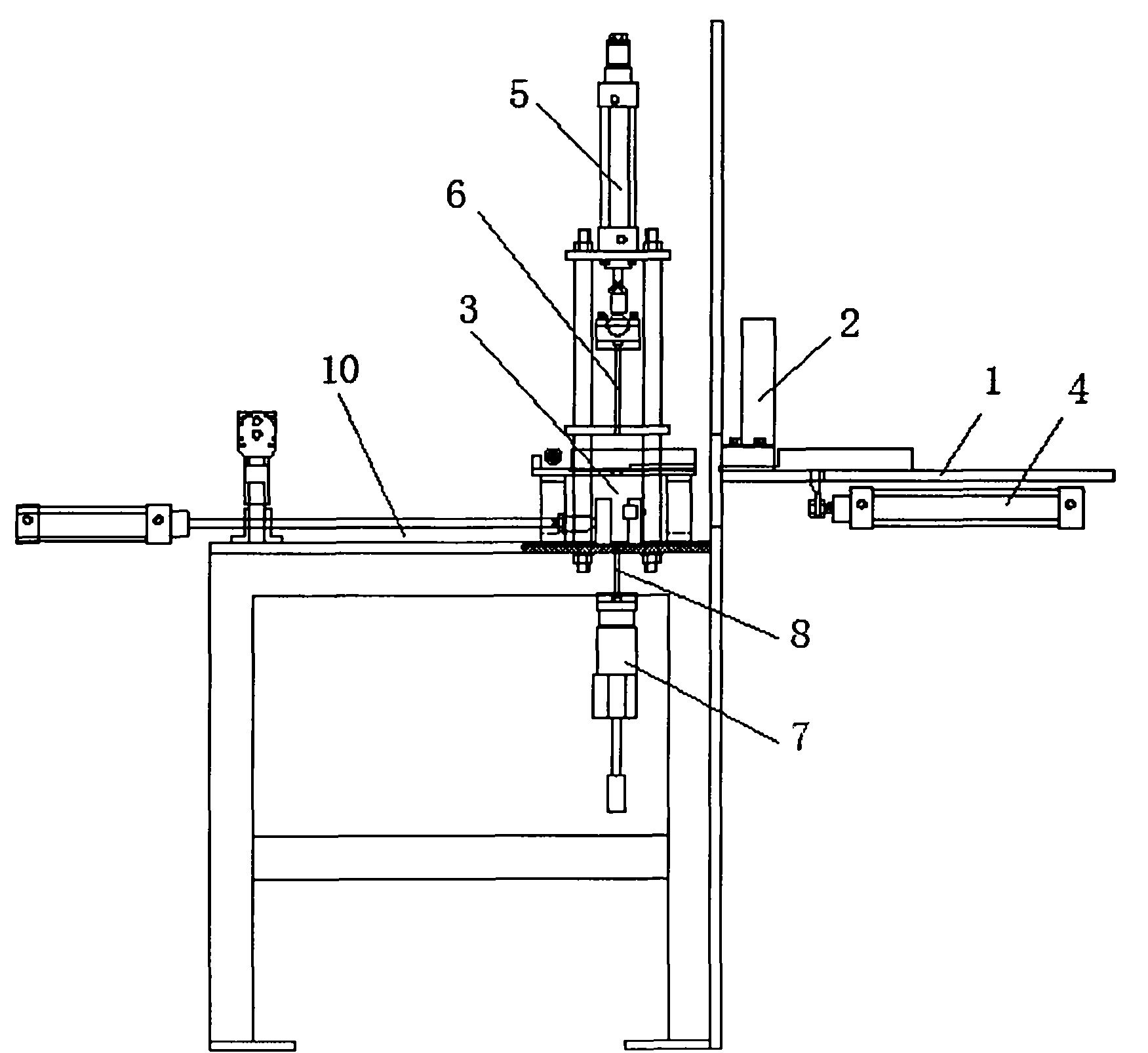

[0018] Such as figure 1 and figure 2 In the automatic lead-discharging and pressing machine shown, the detonator is sent into the rotary frame 13 after being discharged into the detonator mold by the tube-discharging machine in the previous process. Combining station 3, while the upper layer lead core connection mold 2 is pushed into the pressing station 3 by the lead feeding mandrel cylinder 4 on the outer platen 1; distance, so that the nozzle enters the lower die hole of the upper lead core connection die 2, the lead pressing cylinder 5 drives the lead pressing punch bar 6 to press down, the pipe jacking cylinder 7 retracts, and after the lead core is pressed in place, the lead pressing cylinder 5 retracts; The lower layer detonator mold is pulled out by the mould-pulling mechanism 10, and sent to the next station through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com