Composition for preparing SEBS/PP blended grafted modification material and preparation method adopting same

A technology of grafting modification and composition, which is applied in the field of shoe materials, can solve the problems of unstable material quality, low bonding strength, and application limitations, so as to improve the interface bonding ability, meet the lamination tension requirements, and accurately The effect of grafting ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0013] Hereinafter, hydrogenated styrene-butadiene-styrene is abbreviated as SEBS, maleic anhydride is abbreviated as MAH, and polypropylene resin is abbreviated as PP.

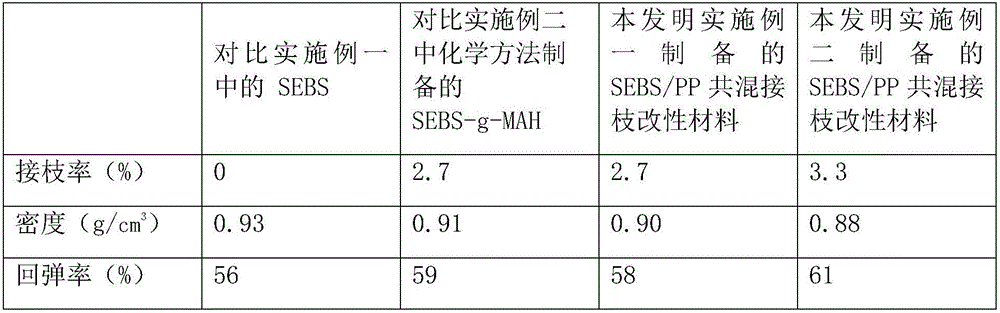

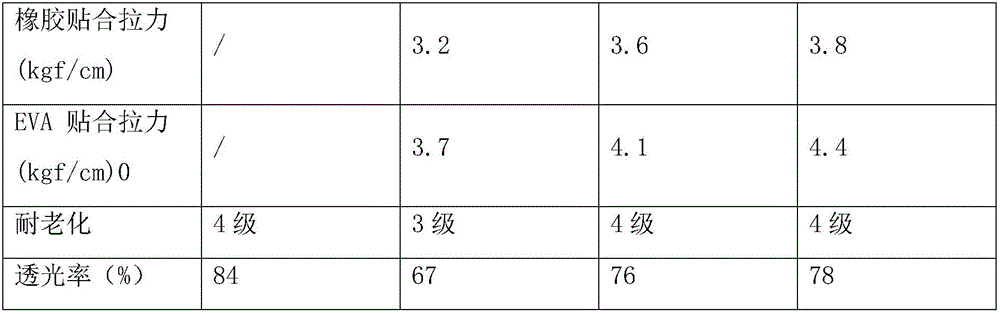

[0014] In Comparative Example 1, SEBS was not grafted; in Comparative Example 2, SEBS was chemically grafted with MAH to obtain SEBS-g-MAH, but it was not blended with PP.

[0015] In Example 1 of the present invention, SEBS is 95 parts by mass, MAH is 5 parts by mass, and PP is 10 parts by mass. The preparation method comprises the following steps: 1) weighing each component according to the mass parts of all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com