Method for recovering pectin from canned citrus alkali treatment water

A canned alkali and water treatment technology, which is applied in the field of waste water reduction and comprehensive utilization of canned fruits and vegetables, can solve the problems of increasing the pre-treatment process and subsequent desalination process, increasing the cost of reagents and the environment, and the high cost of equipment consumables. And the effect of low operating cost, small footprint and low cost of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

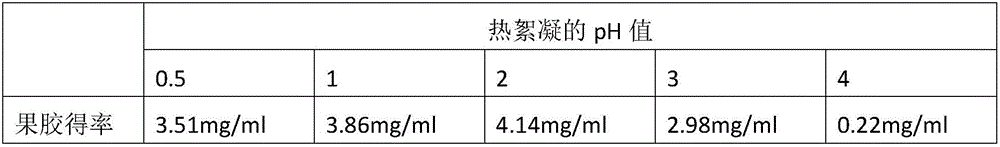

[0038] In this embodiment, concentrated solutions with different pH are used for heating and flocculation to optimize the yield of pectin. The specific steps are as follows:

[0039]Take the alkali-treated water from the canned citrus processing and decapsulation process, and first use a 200-mesh filter cloth to roughly filter it to remove large particle debris such as capsule fragments, orange cores, and orange entanglements. The filtrate uses HCl solution to adjust the pH to 5-7 (the concentration of the HCl solution is not quantitative, and the use of a larger concentration can improve the efficiency of pH adjustment, and a large concentration of HCl requires a large stirring rate). Then use a vacuum concentrator to concentrate under reduced pressure at 50°C, and detect the total solid content online, stop the concentration when the total solid mass fraction is 1.3-1.4%, pump the qualified concentrated solution into the acid-resistant heater, use The mixed acid solution of ...

Embodiment 2

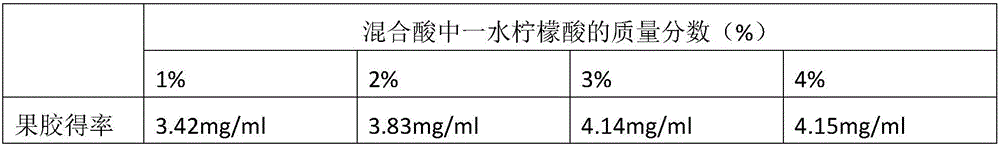

[0043] In this embodiment, mixed acids with different citric acid contents are used as acidity regulators to optimize the yield of pectin. The steps are as follows:

[0044] Take the alkali-treated water from the canned citrus processing and decapsulation process, and first use a 200-mesh filter cloth to roughly filter it to remove large particle debris such as capsule fragments, orange cores, and orange entanglements. The filtrate uses HCl solution to adjust the pH to 5-7 (the concentration of the HCl solution is not quantitative, and the use of a larger concentration can improve the efficiency of pH adjustment, and a large concentration of HCl requires a large stirring rate). Then use a vacuum concentrator to concentrate under reduced pressure at 50°C, and detect the total solid content online, stop concentrating when the total solid mass fraction is 1.6-1.7%, pump the qualified concentrated solution into the acid-resistant heater, use The mixed acid solution of citric acid ...

Embodiment 3

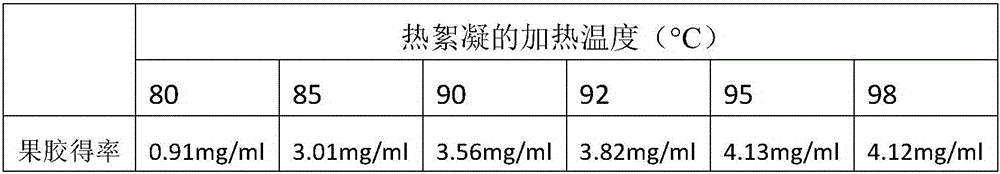

[0048] In this embodiment, different flocculation heating temperatures are used to flocculate the acidic concentrated solution to optimize the yield of pectin. The specific steps are as follows:

[0049] Take the alkali-treated water from the canned citrus processing and decapsulation process, and first use a 200-mesh filter cloth to roughly filter it to remove large particle debris such as capsule fragments, orange cores, and orange entanglements. The filtrate uses HCl solution to adjust the pH to 5-7 (the concentration of the HCl solution is not quantitative, and the use of a larger concentration can improve the efficiency of pH adjustment, and a large concentration of HCl requires a large stirring rate). Then use a vacuum concentrator to concentrate under reduced pressure at 50°C, and detect the total solid content online, stop the concentration when the total solid mass fraction is 1.5-1.6%, pump the qualified concentrated solution into the acid-resistant heater, use The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com