A new rolling ring assembly structure suitable for old drum equipment

An assembly structure and rolling ring technology, applied in mechanical equipment, hoisting devices, components with teeth, etc., can solve problems such as poor relative strength and hardness, weld fatigue, increased deformation, etc., to reduce maintenance costs , increase the benefits of enterprises, and strengthen the effect of rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the contents of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

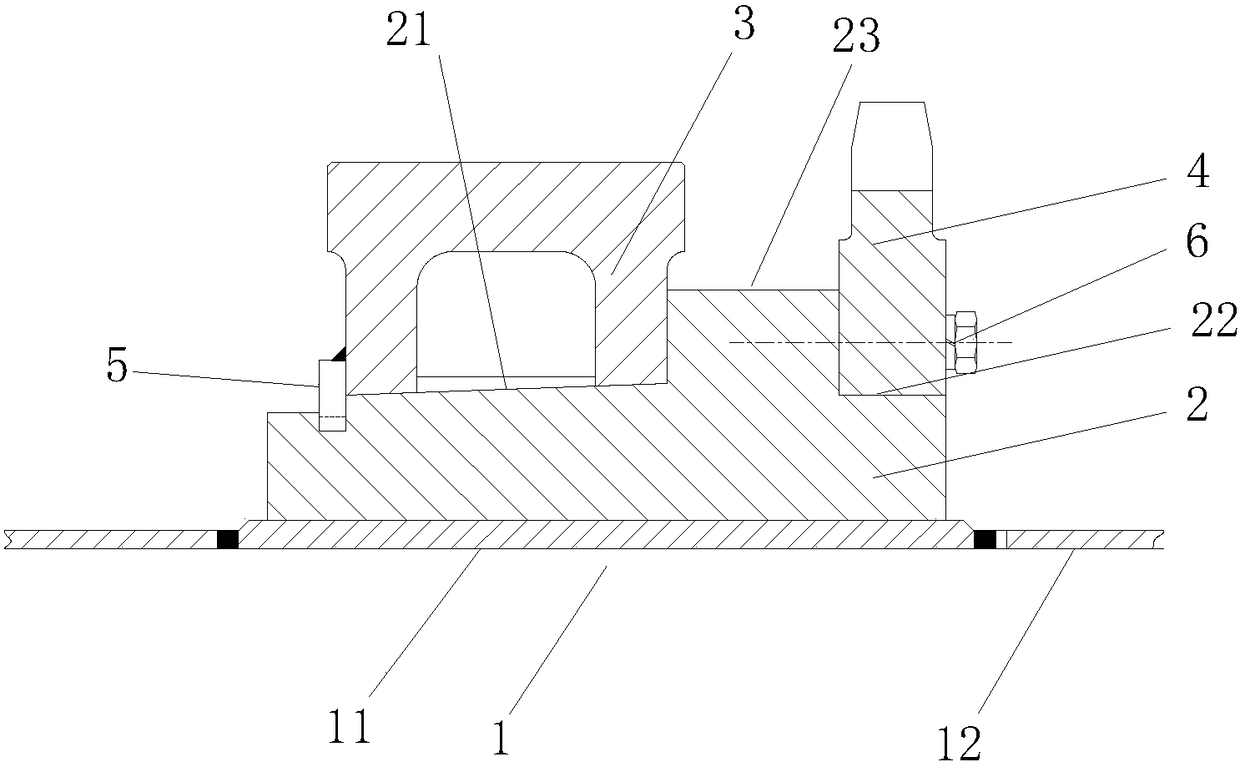

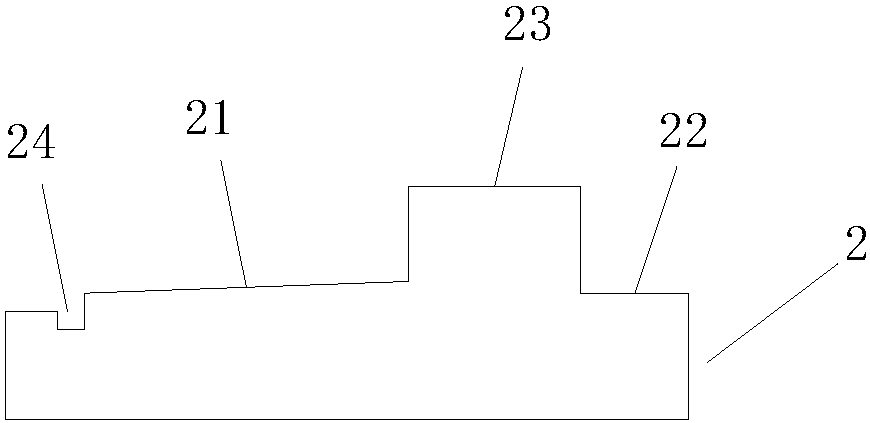

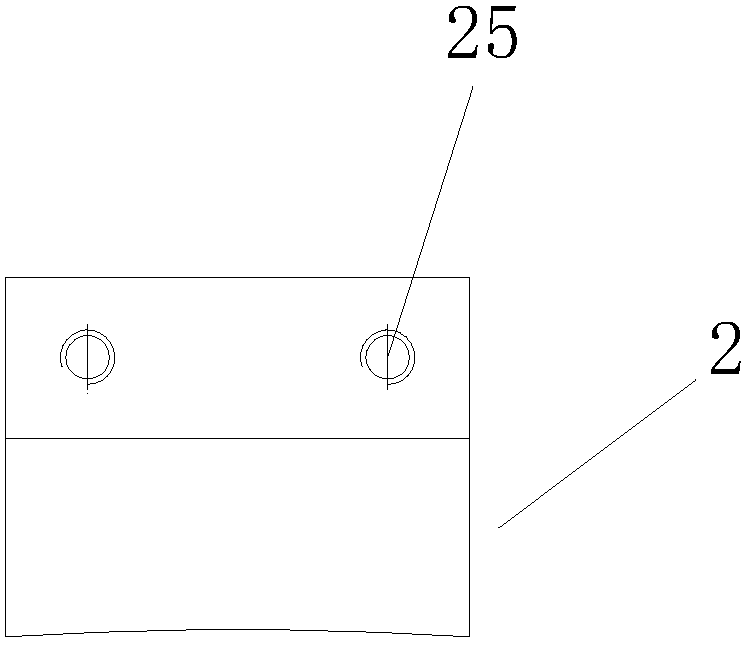

[0030] combine figure 1 , the present invention relates to a new type of rolling ring assembly structure suitable for old drum equipment, including a drum body 1, a rolling ring 3 and a sprocket 4, which also includes a rolling ring spacer 2 and a rolling ring clamping plate 5. The drum body 1 includes a first drum body 11 in the middle of the drum body and a second drum body 12 at two ends, the thickness of the first drum body 11 is thicker than that of the second drum body 12, and the circumference of the two ends of the first drum body 11 Grooves are respectively opened in the directions, and the first drum body 11 is welded to the second drum body 12 at both ends thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com