A multi-rope friction hoist

A friction-type hoist technology, which is applied to lifting equipment, transportation and packaging in mines, can solve problems such as long shutdown and maintenance time, high cost of spare parts, and large amount of equipment maintenance, so as to improve maintenance efficiency and ensure lubrication condition, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

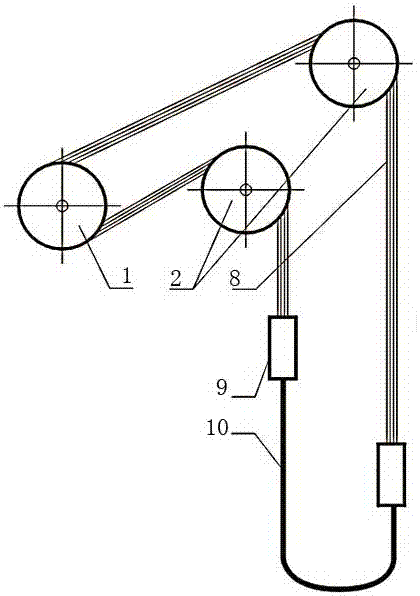

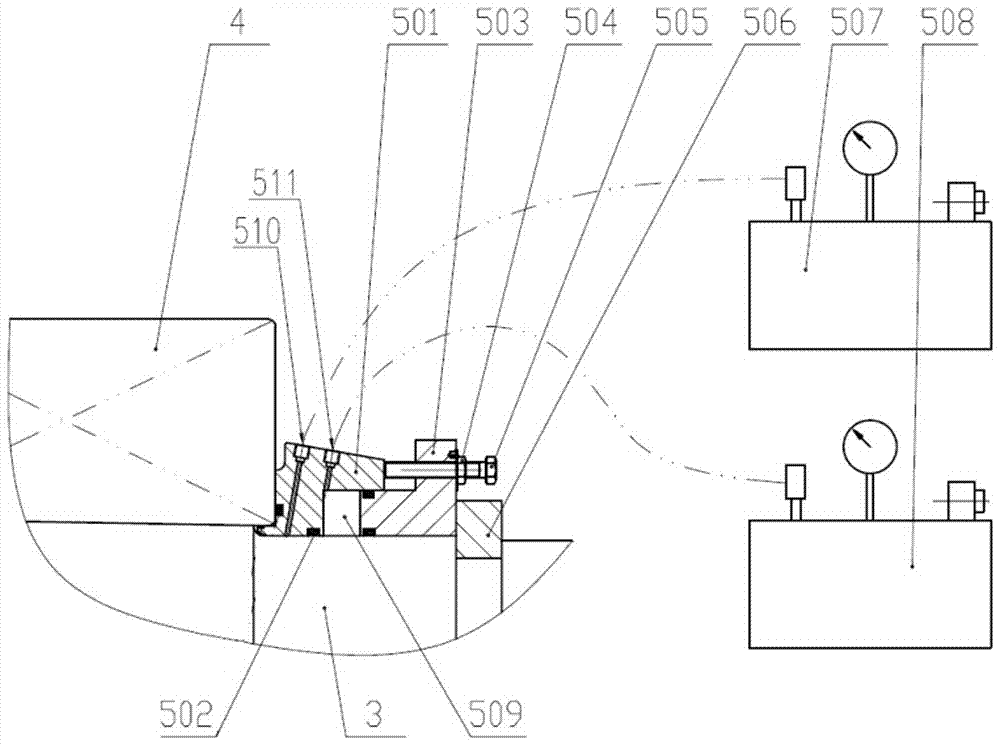

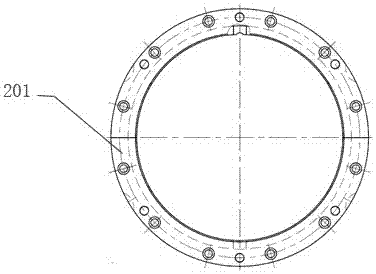

[0024] As shown in the figure, a multi-rope friction hoist includes a power mechanism, a friction wheel 1, a sky wheel 2, a steel wire rope 8, a lifting container 9 and a tail rope 10, and the power mechanism drives the friction wheel 1 to rotate through a main shaft 3. The main shaft 3 is supported on the tapered hole self-aligning roller bearing 4, the main shaft 3 is provided with a dismounting device for the tapered hole self-aligning roller bearing 4, the friction wheel hub 101 and the shaft flange 301 of the main shaft 3 are provided There is a torque transmission device, the traveling wheel 202 hub in the sky wheel 2 is provided with a split copper tile 201 composed of a four-lobe structure, and a copper tile oil injection cleaning device is arranged on the traveling wheel 202, so The friction wheel 1 is provided with a brake disc 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com