Non-pneumatic tire

A technology for non-pneumatic tires and rims, applied in non-pneumatic tires, tire parts, tires, etc., can solve the problems of heavy tire weight, unfavorable impact force, poor shock absorption effect, etc., achieve good aging resistance and prevent mechanical damage , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

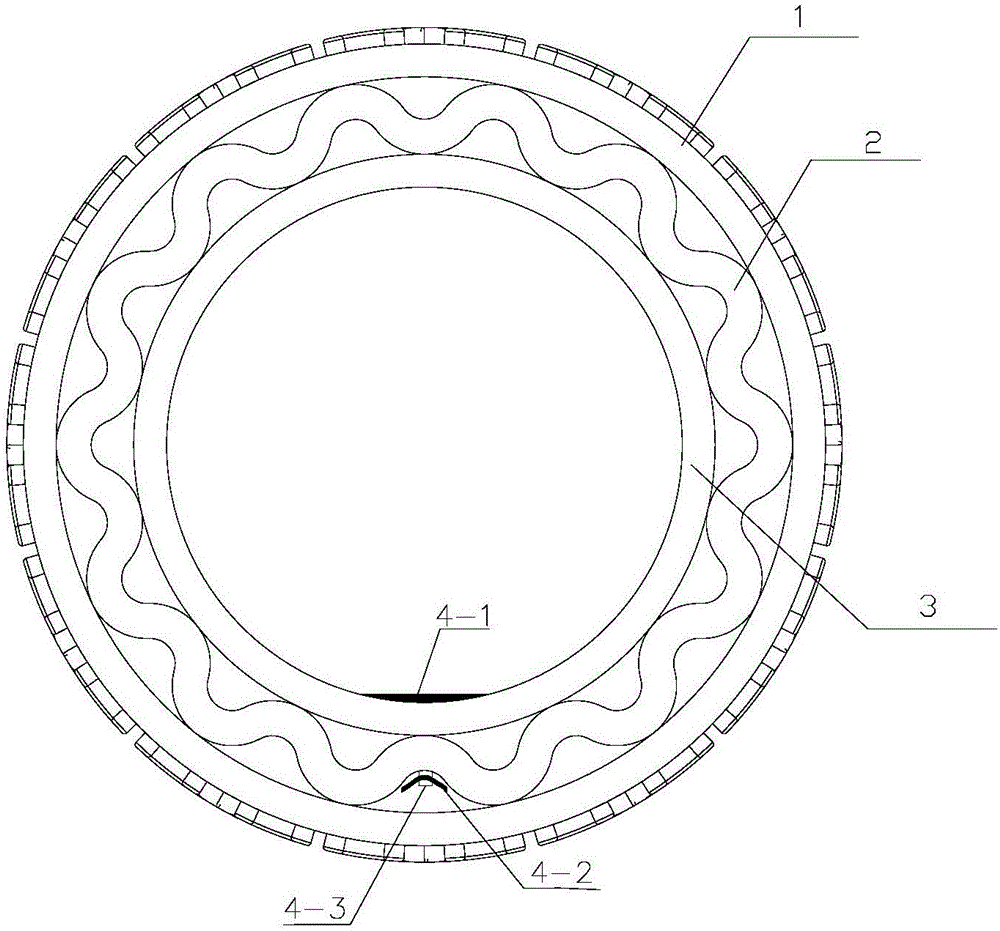

[0029] A non-pneumatic tire, including a rim, on which a tread, a cushioning layer and a rim fitting member are sequentially arranged from the outside to the inside;

[0030] The tread is sequentially composed of tread rubber, transition film I, steel cords, and transition film II from outside to inside;

[0031] The buffer layer has a ring-shaped corrugated structure, the crest of the buffer layer is closely attached to the inner side of the tread, and the trough of the buffer layer is closely attached to the outer side of the rim fitting member; Form a Reloux triangle space between them;

[0032] The buffer layer and the rim matching member are fixed by U-shaped buckles.

[0033] A mold for preparing the above-mentioned non-pneumatic tire, the mold includes a lower heating plate and an upper heating plate, the lower heating plate is provided with an inner heating ring, the outer periphery of the inner heating ring is provided with a buffer layer vulcanization block with a c...

Embodiment 2

[0036] A non-pneumatic tire, including a rim, on which a tread, a cushioning layer and a rim fitting member are sequentially arranged from the outside to the inside;

[0037] The tread is sequentially composed of tread rubber, transition film I, steel cords, and transition film II from outside to inside;

[0038] The buffer layer has a ring-shaped corrugated structure, the crest of the buffer layer is closely attached to the inner side of the tread, and the trough of the buffer layer is closely attached to the outer side of the rim fitting member; A Reloux triangle space is formed between them;

[0039] The buffer layer and the rim matching member are fixed by U-shaped buckles.

[0040] The U-shaped buckle is arranged at the trough of the buffer layer; the trough refers to the nearest part of the ring wave structure close to the rim.

[0041] A mold for preparing the above-mentioned non-pneumatic tire, the mold includes a lower heating plate and an upper heating plate, the l...

Embodiment 3

[0044] A non-pneumatic tire, including a rim, on which a tread, a cushioning layer and a rim fitting member are sequentially arranged from the outside to the inside;

[0045] The tread is sequentially composed of tread rubber, transition film I, steel cords, and transition film II from outside to inside;

[0046] The buffer layer has a ring-shaped corrugated structure, the crest of the buffer layer is closely attached to the inner side of the tread, and the trough of the buffer layer is closely attached to the outer side of the rim fitting member; A Reloux triangle space is formed between them;

[0047] The buffer layer and the rim matching member are fixed by U-shaped buckles.

[0048] The U-shaped buckle is arranged at the trough of the buffer layer; the trough refers to the nearest part of the ring wave structure close to the rim.

[0049] The U-shaped buckle includes a buffer layer fixing part, a rubberized screw and a rim fixing part, and the buffer layer fixing part an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com