A lithium-ion battery tab bending correction device

A lithium-ion battery and tab technology, applied in the field of lithium-ion battery tab bending correction devices, can solve problems such as battery short circuit, large internal resistance, poor welding of the top cover, etc., to achieve vertical compression resistance enhancement, bending The effect of case reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

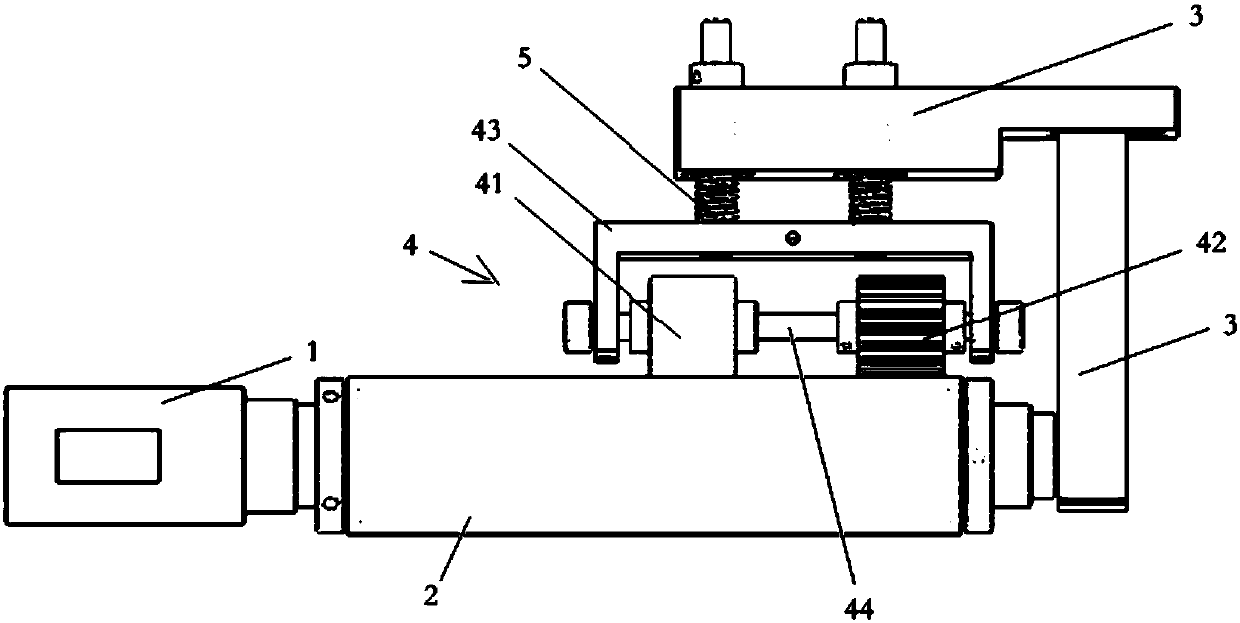

[0016] Such as figure 1 As shown, the lithium-ion battery tab bending correction device includes a cantilever shaft 1 , a rubber-covered roller 2 , an L-shaped bracket 3 , a buffer mechanism 5 and a pressing mechanism 4 . The cantilever shaft 1 is a part of the hoist, the rubber-covered roller 2 is sleeved on the cantilever shaft 1, and rotates with the cantilever shaft, the L-shaped bracket 3 is connected with the front end bearing of the cantilever shaft, and the pressing mechanism 4 passes through the buffer mechanism 5 Connect with L-shaped bracket 3.

[0017] The buffer mechanism 5 adopts a downward pressure spring structure, and the spring is used to increase the pressure of the roller, thereby adjusting the depth of the groove.

[0018] The pressing mechanism 4 includes a pressing roller 41, a straightening roller 42, a linear shaft 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com