Method for removing quartz from kaolin

A technology of kaolin and quartz, which is applied in the field of non-metallic ore kaolin quality improvement and processing, to achieve the effect of good flocculation performance, favorable removal, and extensive cultivation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

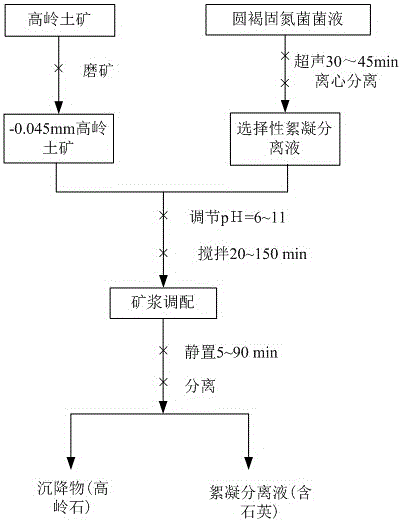

Image

Examples

Embodiment 1

[0019] Embodiment 1: the method for removing quartz in artificial mixed kaolin ore:

[0020] Artificial mixed ore is composed of 90% kaolinite and 10% quartz, Al 2 o 3 and SiO 2 The mass content of Al in kaolinite is 35.28% and 50.67%; 2 o 3 and SiO 2 The mass contents of the crystals are 39.2% and 45.3% respectively; the purity of quartz is 99%.

[0021] The specific steps for removing quartz from kaolin are as follows:

[0022] (1) Grinding kaolin artificial mixed ore until the particle size is below 0.045mm;

[0023] (2) To prepare selective flocculation separation liquid, first press 5.0 g / L sucrose, Na 2 HPO 4 2.0 g / L, MgSO 4 •7H 2 O 1.0g / L, FeCl 3 0.005 g / L, CaCl 2 0.1 g / L, AlCl 3 0.5 g / L, NaSiO 3 •9H 2 O 1.1 g / L prepared microbial growth liquid medium, adjusted the pH value of the medium to 7.3, inoculated the strains of Azotobacter rufica into the Erlenmeyer flask filled with liquid medium, and cultured it in a water bath at 30°C for 96 hours with sh...

Embodiment 2

[0027] Embodiment 2: The method for removing quartz in the kaolin ore sample:

[0028] After graded sand removal, containing Al 2 o 3 and SiO 2 There are fine-grained quartz impurities in the kaolin samples which are respectively 35.28% and 46.50% (mass percentage).

[0029] The specific steps for removing quartz from kaolin are as follows:

[0030] (1) Grinding the kaolin ore sample until the particle size is below 0.045mm;

[0031] (2) To prepare selective flocculation separation liquid, first press 3.0 g / L sucrose, Na 2 HPO 4 1.0 g / L, MgSO 4 •7H 2 O 0.5g / L, FeCl 3 0.005 g / L, CaCl 2 0.2 g / L, AlCl 3 0.75 g / L, NaSiO 3 •9H 2 O 2.0 g / L prepared microbial growth liquid medium, adjusted the pH value of the medium to 7.0, inoculated the strains of Azotobacter rufica into an Erlenmeyer flask filled with liquid medium, and cultured it in a water bath at 28°C for 72 h with shaking, and shaken The rotation speed was 200 r / min to obtain the culture solution of Azotobact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com