A porous ceramic dust collector

A technology for porous ceramics and dust collectors, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve problems such as cracks in the head of the porous ceramic tube, complex nozzle installation structure, affecting stable operation, etc. Filtration rate, simple structure, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

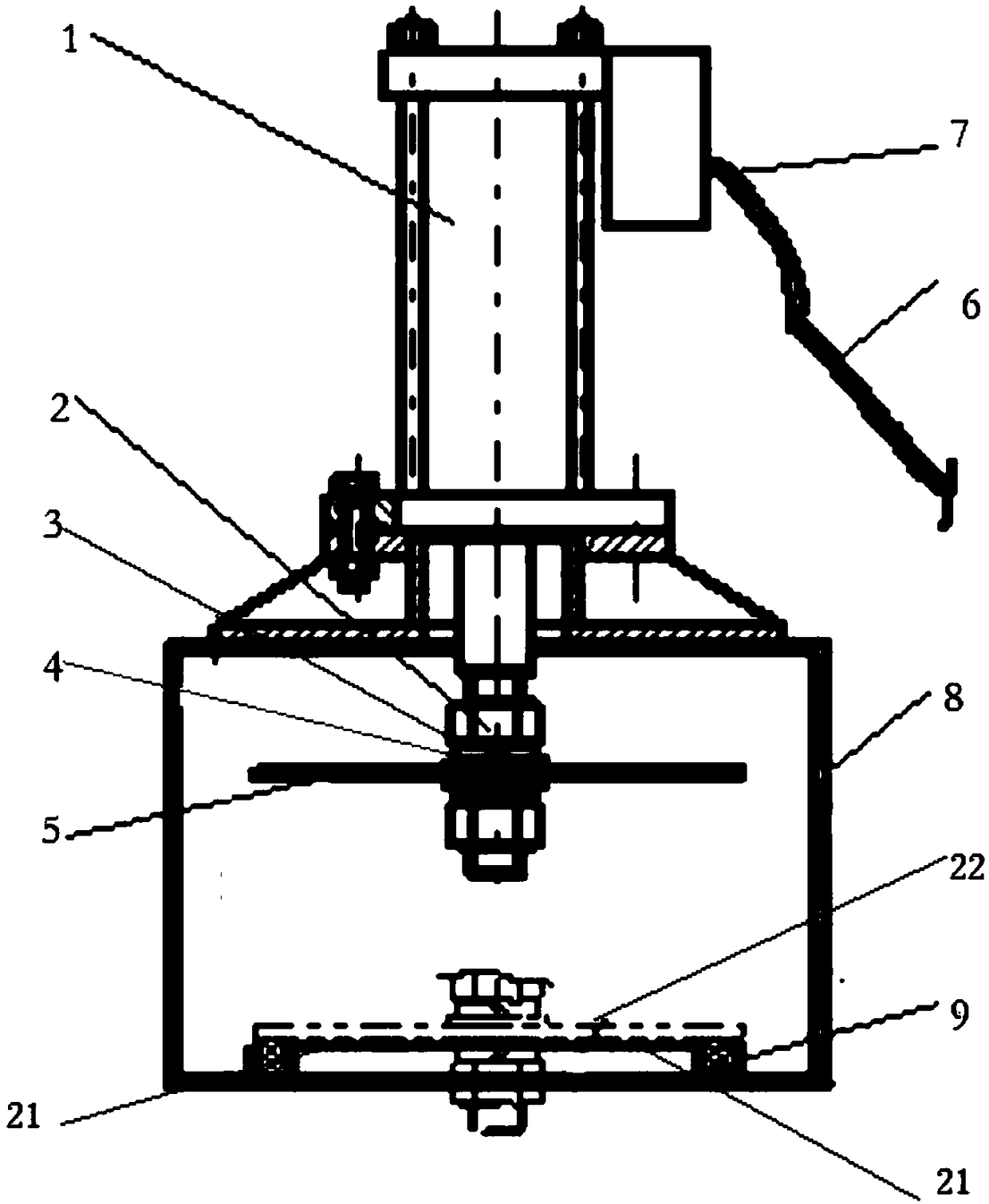

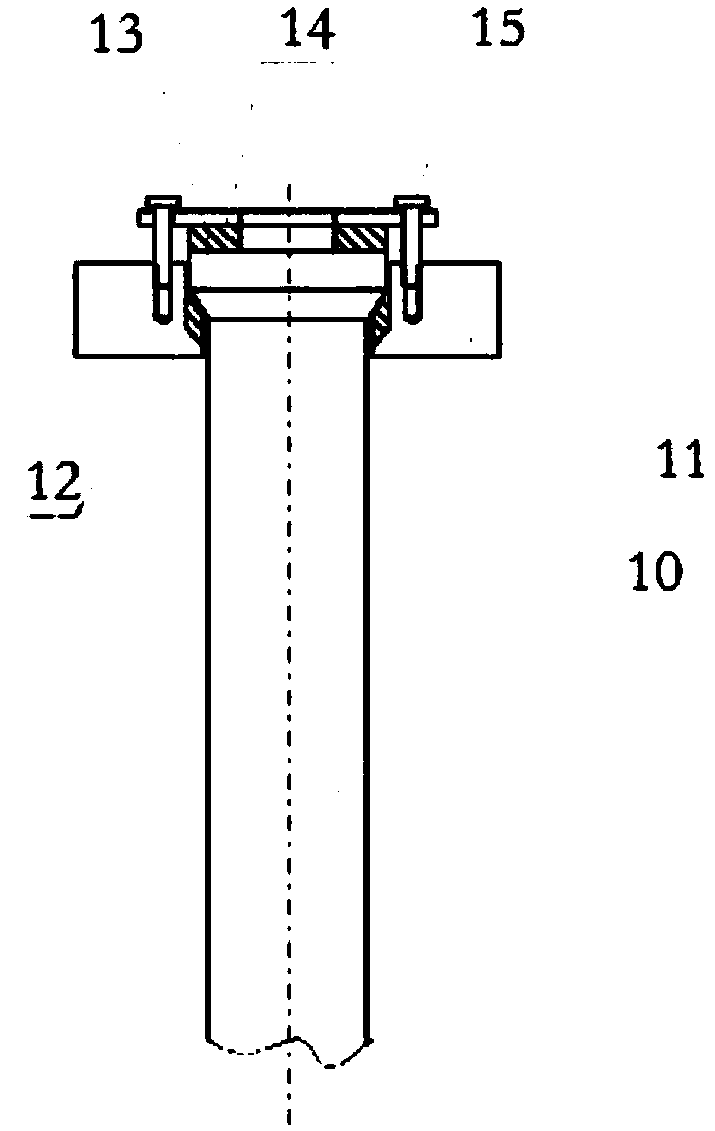

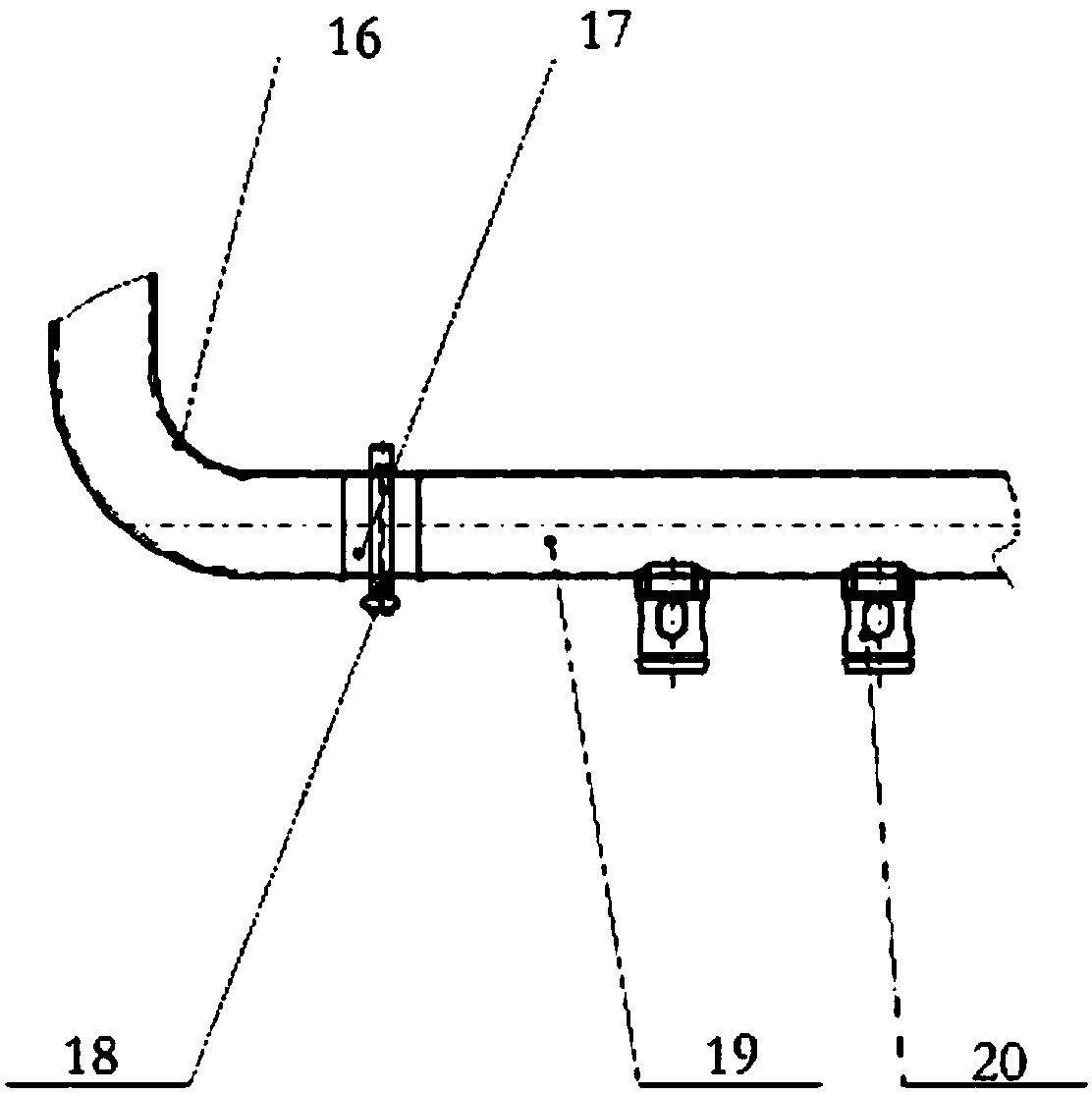

[0020] Embodiment 1: A kind of porous ceramic dust collector, the porous ceramic filter core is arranged between the inlet and the outlet of the dust collector, it is characterized in that it also includes an emergency bypass device, an installation fixing device and a quick connection device, wherein the emergency bypass device is provided with A valved cylinder (1) equipped with a solenoid valve, a valve plate (5) is arranged at the bottom of the cylinder; the valve plate (5) is fixed by a nut (2), a flat washer (3), and a spring washer (4). Trachea (6) and copper gas nozzle (7). The valved cylinder is installed on the base (8), and there are air holes on both sides of the base (8), and a circular graphite gasket (9) for sealing is arranged around the bypass hole (21) of the partition; the porous ceramic tube in the installation and fixing device (10) One end is an arc-shaped transition, and the tube sealing gasket (12) is made of graphite material, which is made into a doub...

Embodiment 2

[0023] Embodiment 2: A kind of porous ceramic dust collector, a porous ceramic filter element is arranged between the inlet and the outlet of the dust collector, and it is characterized in that it also includes an emergency bypass device, a mounting fixture and a quick connection device, wherein the emergency bypass device is provided with A valved cylinder (1) equipped with a solenoid valve, a valve plate (5) is arranged at the bottom of the cylinder; the valve plate (5) is fixed by a nut (2), a flat washer (3), and a spring washer (4). Trachea (6) and copper gas nozzle (7). The valved cylinder is installed on the base (8), and there are air holes on both sides of the base (8), and a circular graphite gasket (9) for sealing is arranged around the bypass hole (21) of the partition; the porous ceramic tube in the installation and fixing device (10) One end is an arc-shaped transition, and the tube sealing gasket (12) is made of graphite material, which is made into a double arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com