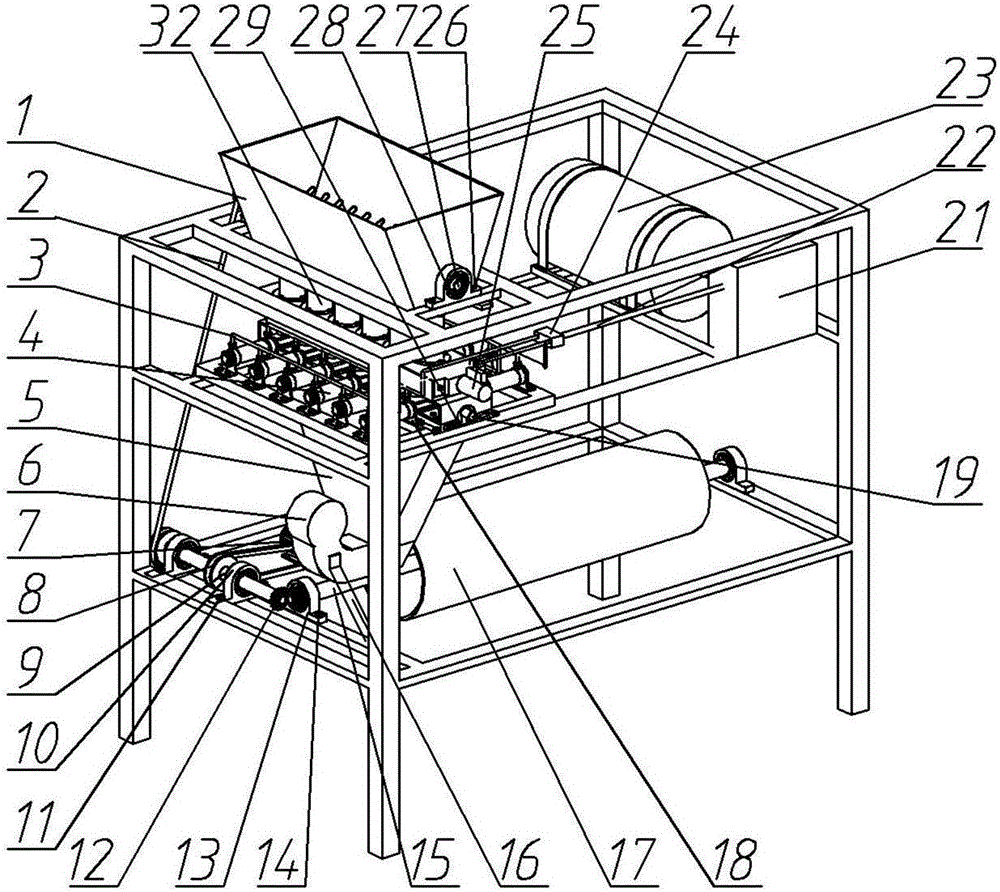

Chestnut sheller with positioned conveying and usage thereof

A shell breaking device, walnut technology, applied in the direction of shelling, application, pod removal, etc., can solve the problem of inefficient control of walnut feeding and shell breaking process, fine control of positioning, random and uncontrollable walnut posture and other issues to achieve the effects of reducing labor costs, flexible and adjustable speed, and precise and controllable attitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

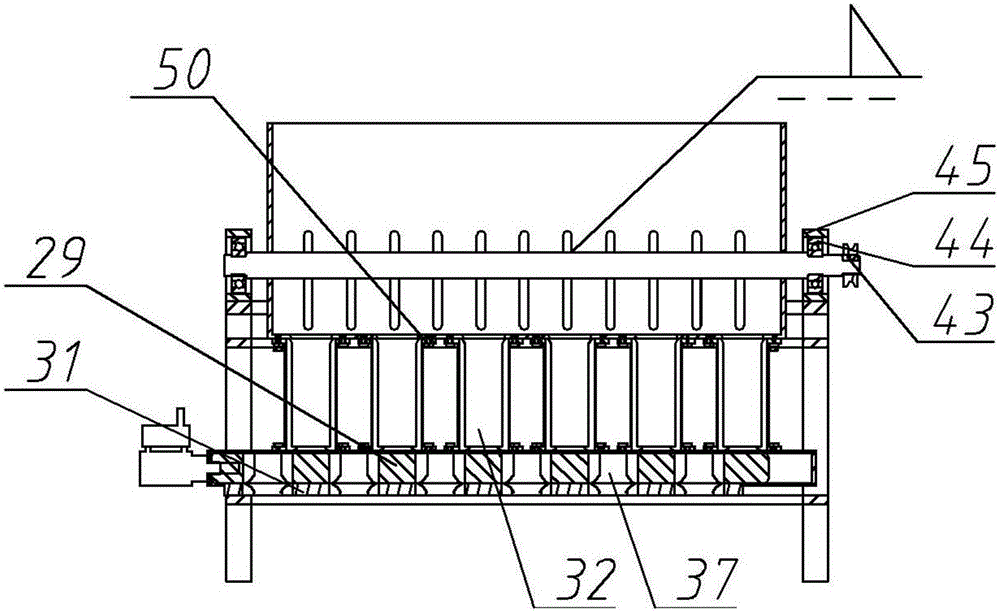

[0080] The difference between this embodiment and embodiment 1 is:

[0081] The walnut shelling device with positioning conveying includes at least one walnut fixing mechanism and at least two impact bars arranged on the frame, the walnut shelling mold is provided with walnut positioning grooves, and the side wall of the walnut shelling mold is provided with at least two The openings connected to the walnut positioning grooves, driven by the moving mechanism, a plurality of striking rods pass through the openings corresponding to each striking rod to strike the walnuts arranged in the walnut positioning grooves, and also include the walnuts arranged on one side of the walnut positioning grooves for The positioning and quantitative feeding slider covering the walnut positioning groove, the positioning and quantitative feeding slider is provided with several through holes, when the walnut shell breaking mold is set horizontally, the positioning and quantitative feeding slider is ...

Embodiment 3

[0083] The difference between this embodiment and embodiment 1 is:

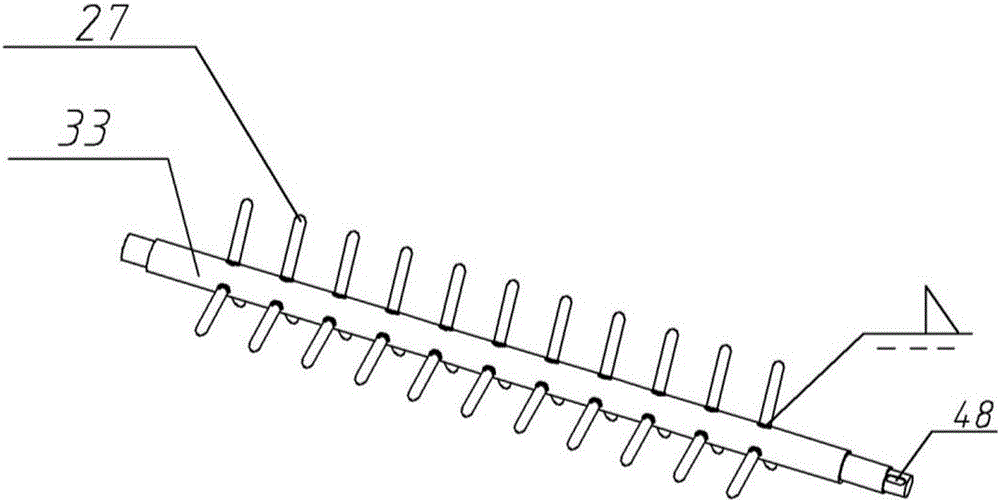

[0084] A baffle plate with holes is set below the walnut positioning mold, such as Figure 16 As shown, in the initial position, the through holes 13 of the baffle are interlaced with the positions of the walnut positioning holes, so as to stop the walnut from falling. Plate reversing cylinder 19 is provided with perforated baffle plate reversing cylinder gas injection hole 62 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com