Straw picking, dust removal processing machine

An all-in-one machine and straw technology, applied in the field of agricultural machinery, can solve the problems of dust removal, soil removal, impact on livestock health, and combustion of straw that cannot be picked up, and achieve convenient storage and transportation, convenient packing operation, compact and compact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

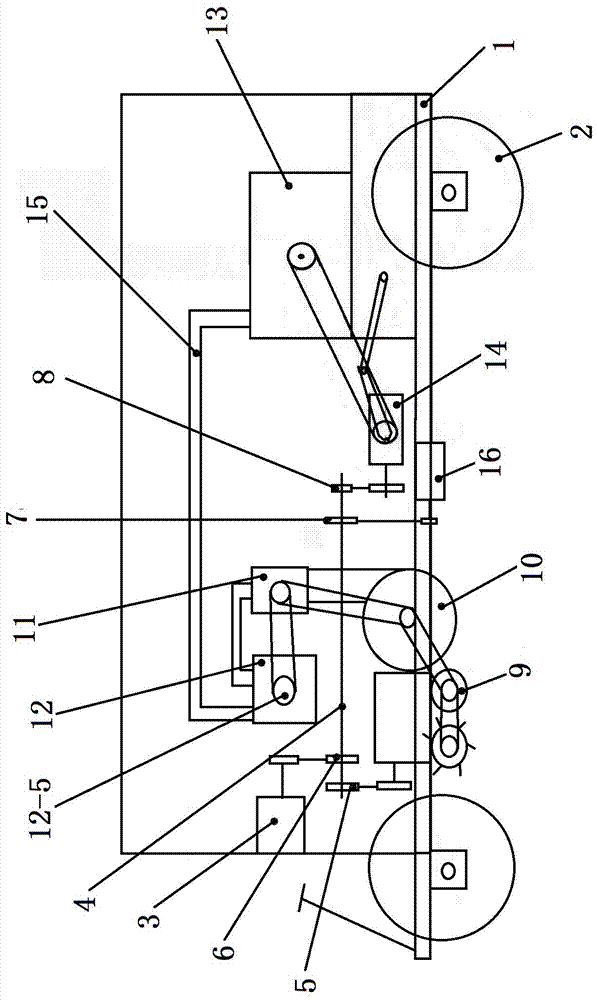

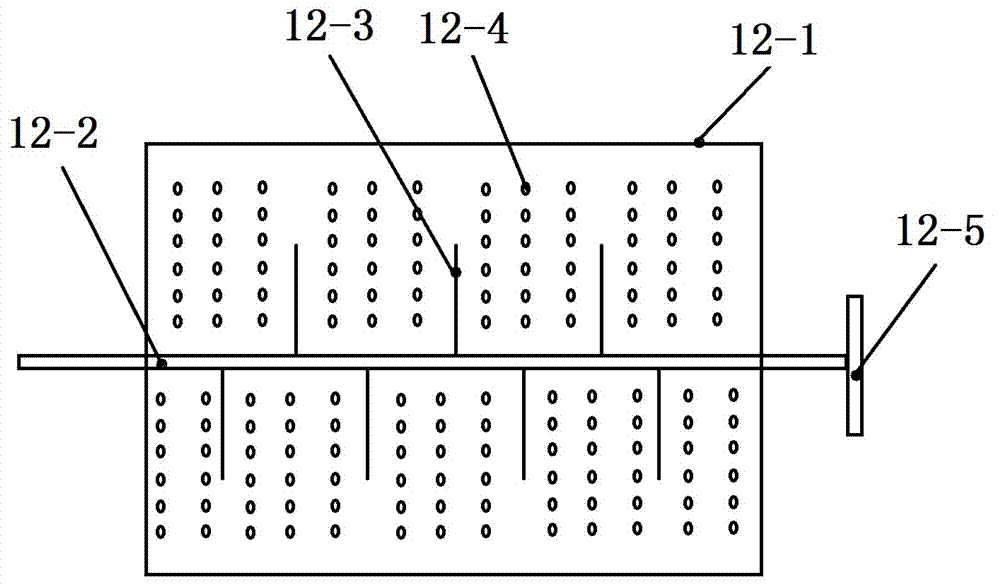

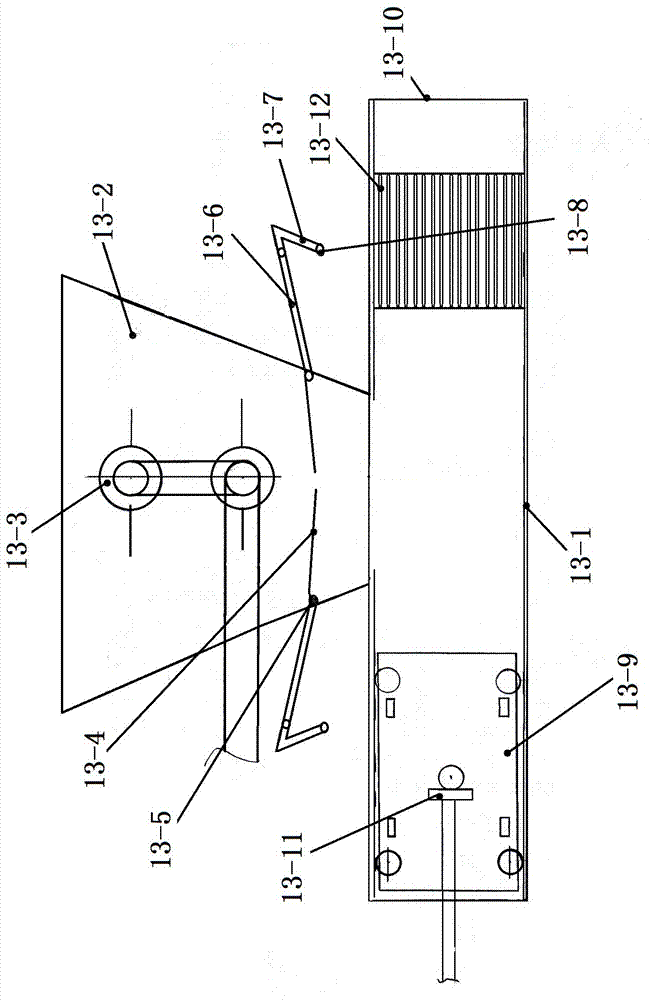

[0015] refer to figure 1 , it includes frame 1, wheel 2 is mounted on the frame through the front and rear axles, the frame is provided with seat, steering wheel, engine 3, transition shaft 4 is mounted on the frame through bearings, and there are four sprockets on the transition shaft , are respectively the first sprocket 5, the second sprocket 6, the third sprocket 7, the fourth sprocket 8, and the frame is also provided with a pickup 9, a hay cutter 10, a rubbing machine 11, a dust collector 12 and Packing machine 13, the sprocket wheel on the engine power output shaft and the second sprocket wheel 6 on the transition shaft are connected by a chain, and the first sprocket wheel 5 on the transition shaft is connected with the sprocket wheel on the pick-up power input shaft by a chain, picking up The discharge end of the picker corresponds to the feed port of the chaff cutter. There is a sprocket on the main shaft of the picker, and there are two sprockets on the main shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com