A photoacoustic composite three-dimensional micro-nano imaging detection system and method

An imaging detection and three-dimensional technology, which is applied in the direction of optical testing of flaws/defects, measuring devices, and material analysis through optical means, can solve the problems of reliability testing and quality control technology lagging behind manufacturing technology, destroying the integrity of microelectronic packaging samples, Can not solve problems such as microelectronic packaging detection, and achieve the effect of easy promotion and use, high detection accuracy and reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

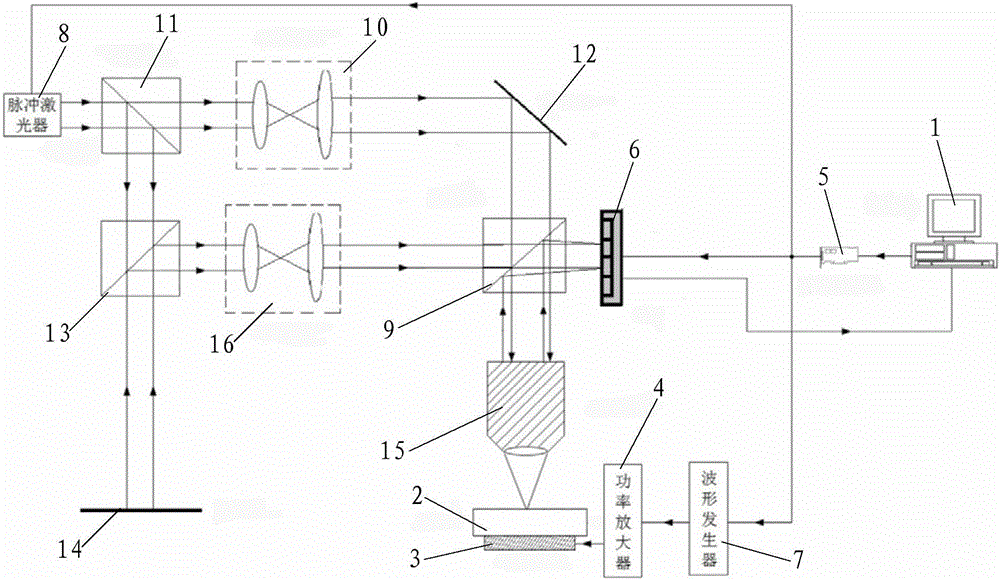

[0049] Such as figure 1 As shown, the photoacoustic composite three-dimensional micro-nano imaging detection system of the present invention includes an optical holographic optical path, and also includes a computer 1, a microscope 15, a piezoelectric wafer 3 for placing a solid sample 2, and a device for driving the piezoelectric wafer 3 to vibrate. Power amplifier 4, described computer 1 is connected with synchronous controller 5 and the digital camera 6 that is connected with synchronous controller 5, and described synchronous controller 5 is connected with waveform generator 7 and pulsed laser 8, and described power amplifier 4 Be connected with the output end of waveform generator 7, described piezoelectric chip 3 is connected with the output end of power amplifier 4; Described optical holographic optical path comprises object light optical path, reference light optical path and the first beam splitter cubic mirror 9, and described object The optical path includes a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com