System for testing damage threshold of optical element surface and test method

A surface damage and optical component technology, applied in the field of optical inspection, can solve the problems of reducing damage correlation, inaccurate description of defect damage threshold, inaccurate test results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

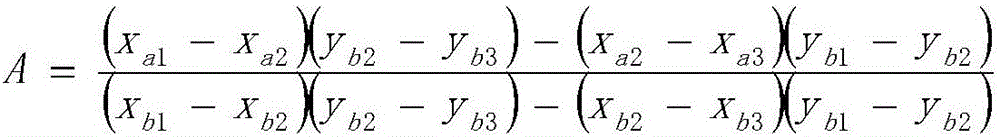

Method used

Image

Examples

Embodiment 1

[0069] Such as figure 1 and 2 As shown, the present embodiment provides a damage threshold testing system for the surface of an optical element. The high-energy laser (wavelength 351 nm, pulse width 5 ns) emitted by the laser 1 is converged by the laser after being shaped by the liquid crystal light valve 2 through the lens 4. After reaching the surface of the sample 5 to be measured, it enters the absorption trap 6; at the same time, the laser light reflected by the beam splitter 3 is collected and collected by the mirror 8. The laser light reflected by the mirror 8 is converged to the monitoring CCD 11 through the lens 10, and the transmitted laser light enters the energy card meter 9, and is collected through the second lens. 10 converged laser spot near field, record and monitor CCD11 data, and record card meter 9 energy data.

[0070] According to the R-on-1 damage threshold test process, the laser energy was increased in steps of fixed energy until damage points appeare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com