Computer controlled metal material indentation load-displacement data measurement system

A metal material, press-in load technology, applied in the direction of measuring device, analyzing material, testing material hardness, etc., to achieve the effect of easy installation, reliable installation, reliability and anti-interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing:

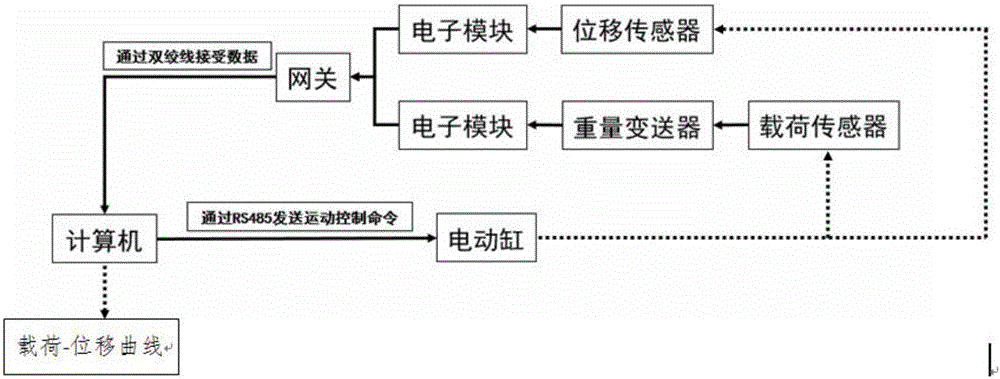

[0032] The present invention is to use computer-controlled metal material indentation load-displacement curve indentation test system, such as Figure 1-2 shown. The test system includes mechanical part and electrical part. The computer communicates with the servo linear motor through RS485 serial communication and with the load / displacement sensor through a protocol converter (gateway) for TCP / IP communication.

[0033] The mechanical part includes a servo linear motor (1), a spherical indenter (6), an indenter handle (7), a load sensor (5) and a displacement sensor (11).

[0034]The servo linear motor (1) is the TritexII AC T2M075 integrated roller screw linear electric servo actuator of the American EXLAR company. This servo linear motor combines the AC-powered servo driver, digital positioning controller, brushless servo Units are integrated in a fully sealed unit. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com