Water-purifying electric water heater

A water heater, water purification technology, applied in water heaters, fluid heaters, water/sewage treatment, etc., can solve the problems of inconvenient replacement of filter elements, short service life of filter elements, unreasonable structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

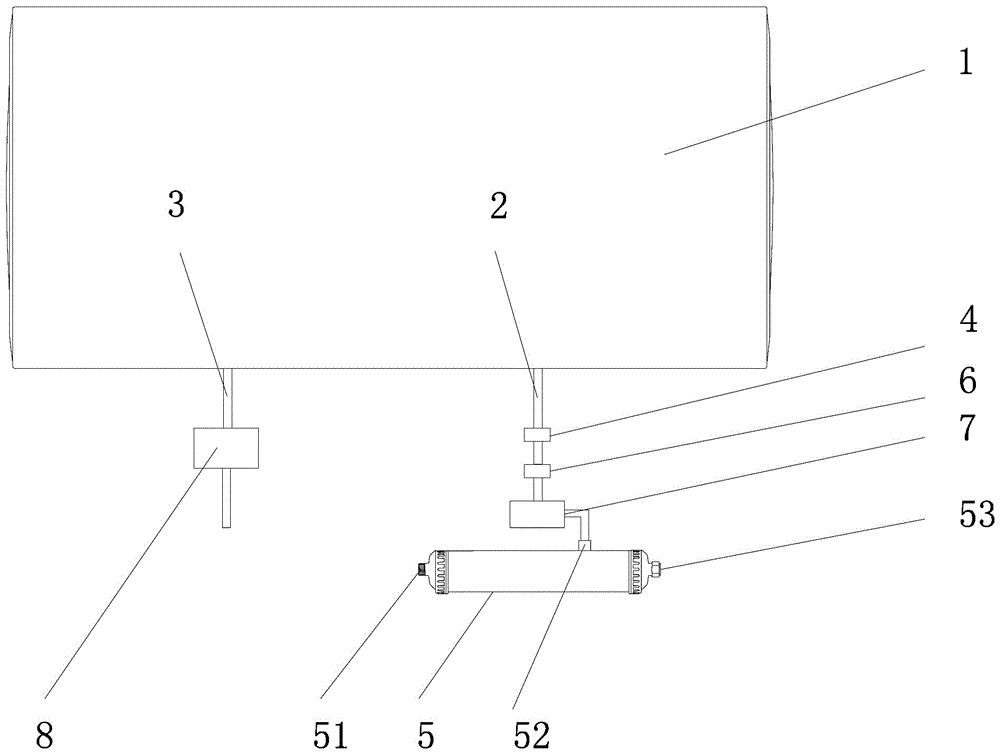

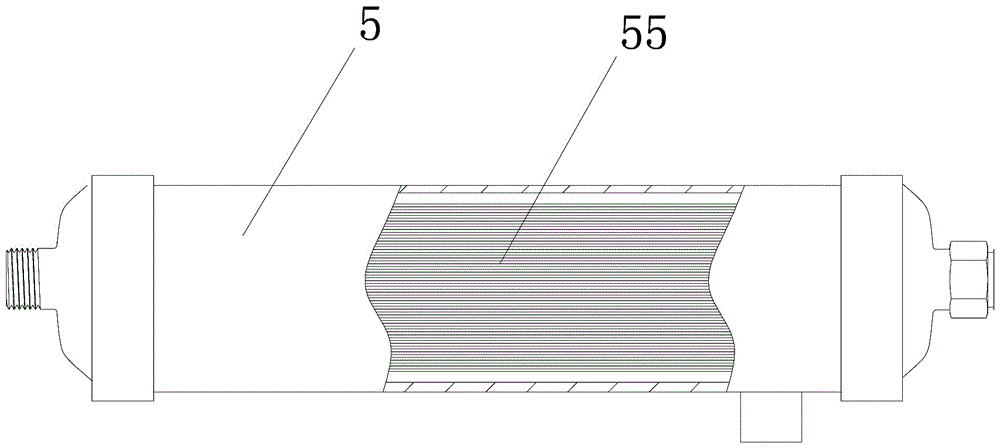

[0026] like figure 1 , 3 As shown, the clean water electric water heater includes a housing, an inner tank 1, an insulation layer, a water heater inlet pipe 2, a water heater outlet pipe 3, and a first filter cartridge 5, which is provided with a filter cartridge water inlet 51, a filter The cylinder water outlet 52, the sewage outlet 53, and the filter cylinder water outlet are connected to the water heater inlet pipe. The water heater inlet pipe is provided with a one-way valve 6 for preventing the hot water in the inner tank of the water heater from flowing back into the filter cartridge. A hollow fiber membrane filter tube 55, the filter cartridge water inlet and the filter cartridge water outlet are arranged at both ends of the filter cartridge along the axial direction of the hollow fiber filter membrane tube, and hundreds of millions of holes are distributed on the side wall of the hollow fiber filter membrane tube. pores in microns. The water heater inlet pipe is als...

Embodiment 2

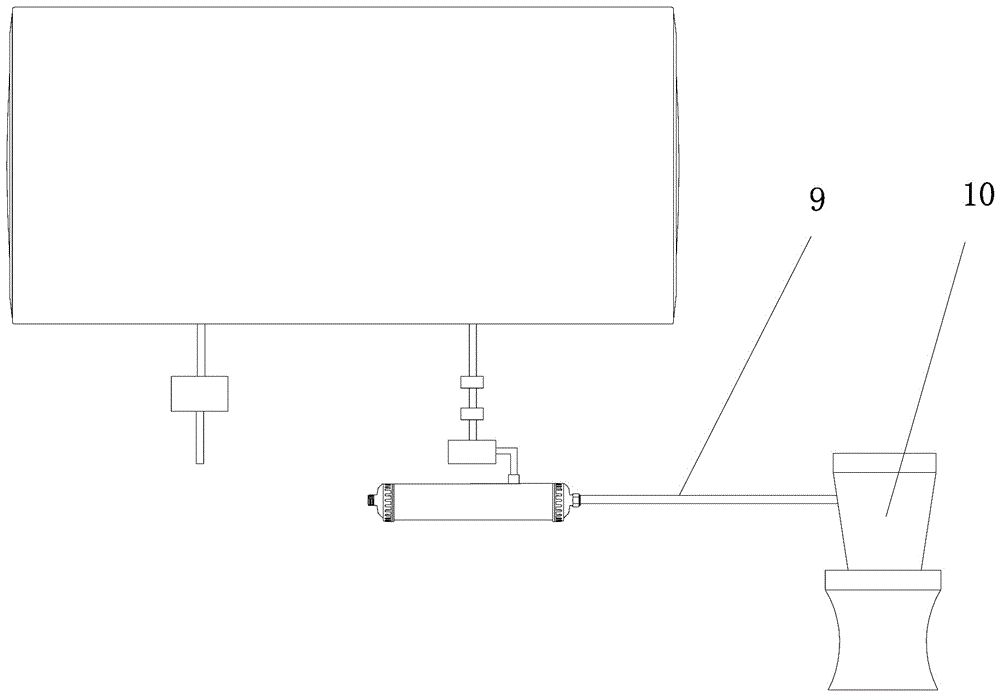

[0031] Embodiment two is based on embodiment one, and make following improvement: as figure 2 As shown, the sewage outlet of the first filter cartridge is connected to the drainpipe 9, and the other end of the drainpipe 9 is connected to the water inlet of the toilet 10 or the water inlet side of the faucet of the washbasin. After setting like this, the cleaning of the filter element of the first filter cartridge becomes a part of daily life, and the tap water through the first filter cartridge is used for flushing of the flush toilet or daily washing, which is environmentally friendly and energy-saving, and can also clean the filter element. The design is reasonable and scientific.

Embodiment 3

[0033] Embodiment 2 is based on Embodiment 1 or Embodiment 2, and makes the pipe connection relationship of the water heater filter system more specific. like Figure 4 As shown, the water heater inlet pipe 2 and the water heater outlet pipe 3 are connected to the water mixing valve 11, the filter cartridge outlet of the first filter cartridge is connected to the tee 13, one side of the tee is connected to the water purification valve 12, and the other side of the tee is connected to the water purification valve 12. The water heater inlet pipe 2 and the cold water side of the water mixing valve 11 are connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com