Feeding system of dangerous waste incinerator

A feeding system, hazardous waste technology, applied in the direction of incinerators, furnaces, combustion methods, etc., can solve problems such as impact, poor feeding, polluted water and soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

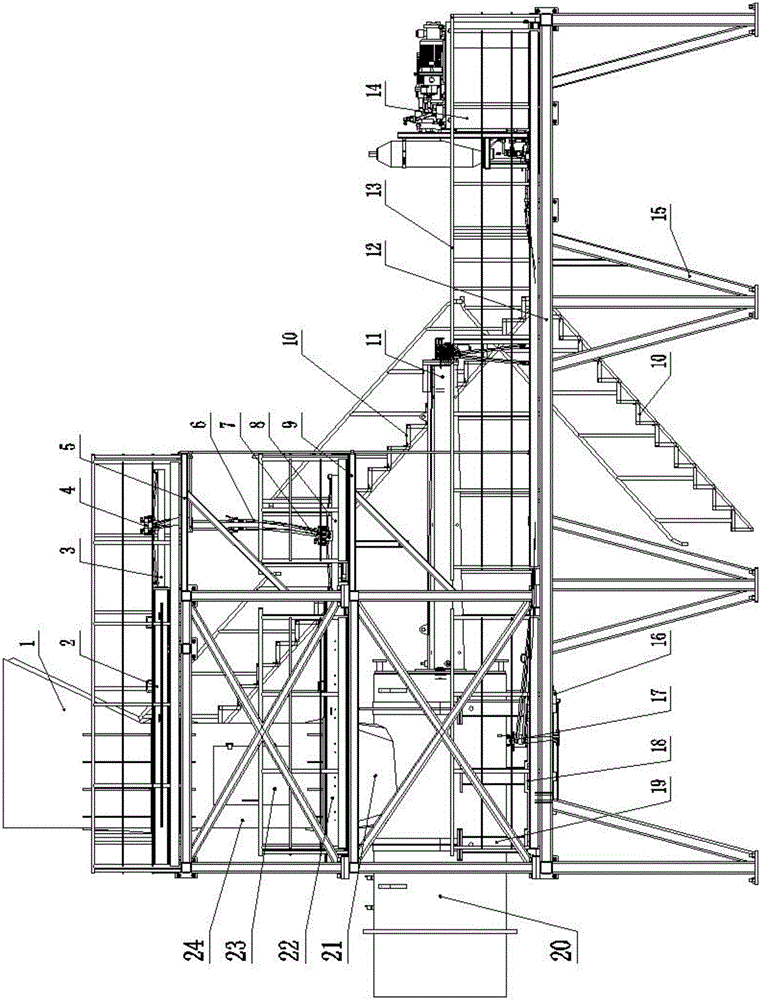

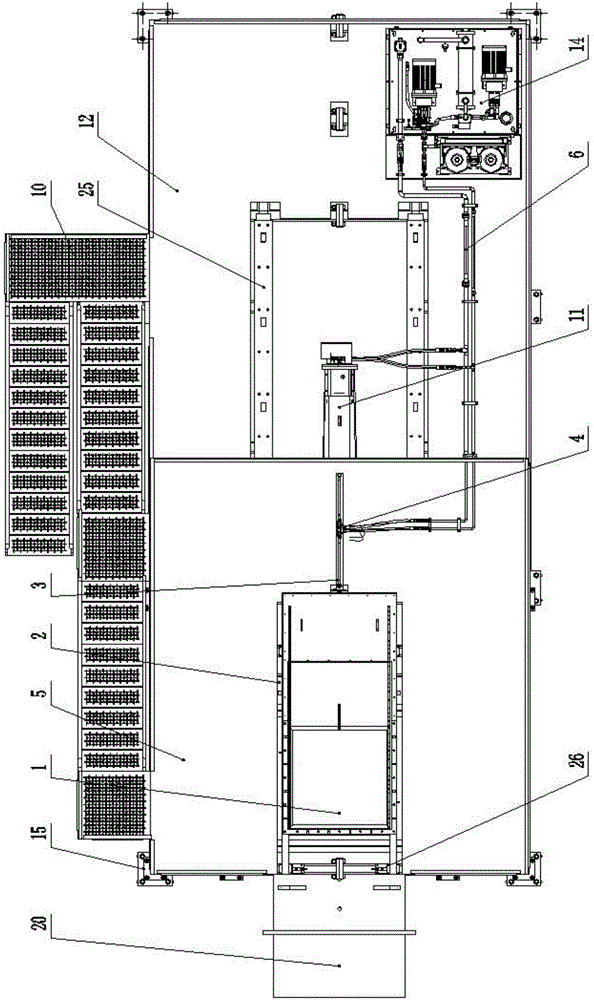

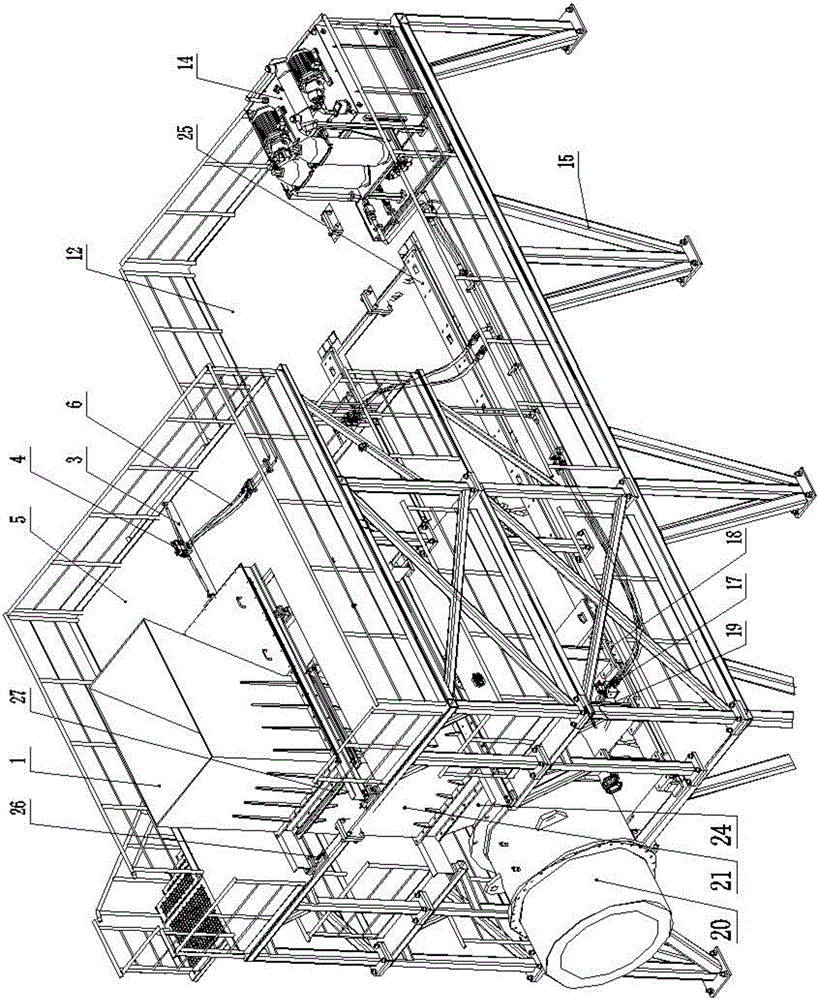

[0025] A hazardous waste incinerator feeding system such as Figure 1-7 As shown, the innovation of the present invention is: comprising a bracket, a hopper 1 and a main pusher cylinder 20, the main pusher cylinder is horizontally installed on the support, and a hopper for hazardous waste is installed on the feed port 43 of the main pusher cylinder, located on the support The end face of the main pusher cylinder inside is equipped with a pusher cylinder 11, the pusher piston 40 of the pusher cylinder is located in the main pusher cylinder, and the end face of the main pusher cylinder outside the bracket is made with an opening 42 for the pusher piston to push out hazardous waste. A feed gate 34 capable of opening and closing is embedded i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com