A self-sensing self-healing concrete component

A concrete, self-healing technology, applied in building components, building structures, buildings, etc., can solve problems such as unsatisfactory effects, reduce concrete strength and toughness, and achieve improved tensile strength, enhanced fracture toughness and impact resistance, Avoid cracking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

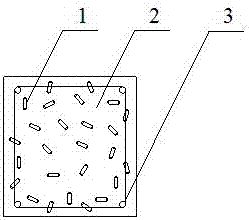

[0025] please see Figure 1-Figure 4 , a kind of self-sensing and self-healing concrete member provided by the present invention, in the process of mixing concrete 2, put steel capsule 1, after stirring evenly, pour into the reinforcement cage 3 installed in place in advance; The locations in the concrete 2 are evenly distributed, and the orientation of the steel capsule 1 is random.

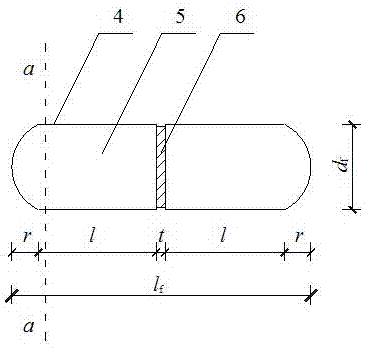

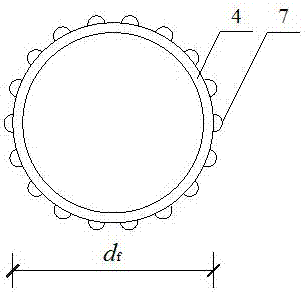

[0026] The steel capsule 1 of this embodiment is composed of a steel capsule wall 4, structural glue 5, and ring-shaped ceramics 6; In order to ensure that the strength and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com