Assembly type cement pavement construction method

A construction method and prefabricated technology, which is applied in the field of prefabricated cement concrete pavement construction, cement concrete pavement construction or reconstruction engineering, can solve the problem of force coordination between slabs, pavement disease prevention and control, lack of road performance improvement, difficult to solve concrete Problems such as plate temperature stress and local stress concentration can be improved to improve the ability of disease prevention and control, shorten the construction period, and control differential deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

[0045] Cement concrete slab design and pouring construction technical requirements, road base design and construction technical requirements, road subgrade design and construction technical requirements, steel bar binding construction technical requirements, road shoulder design and construction technical requirements, etc., will not be repeated in this implementation mode, and will focus on The invention relates to embodiments of the method.

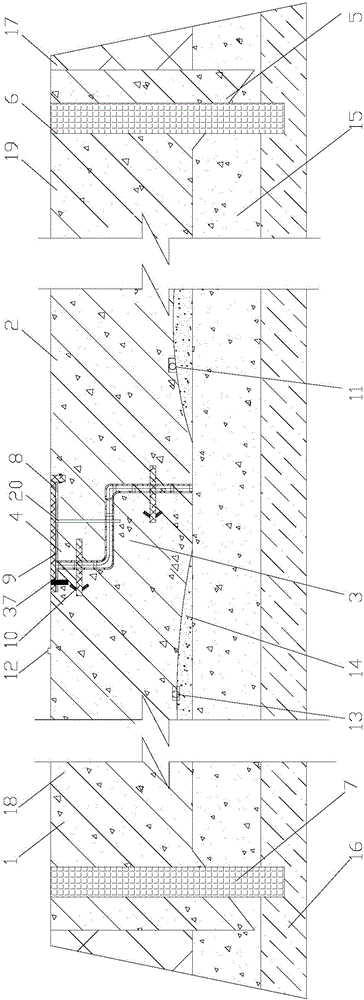

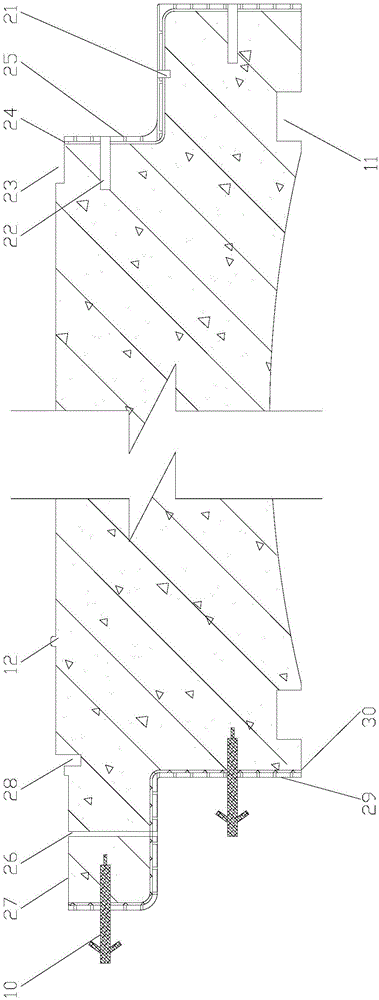

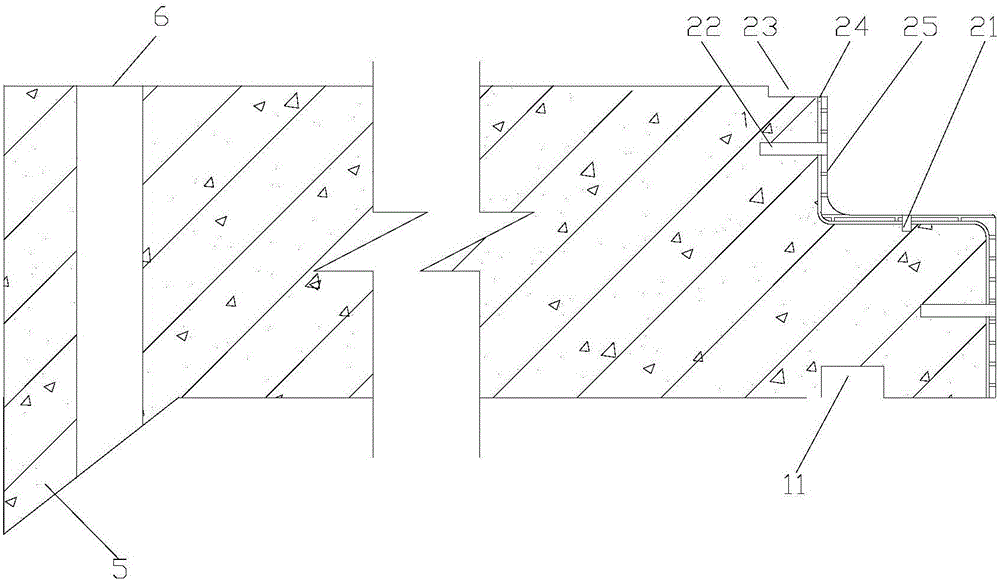

[0046] figure 1 It is a cross-sectional schematic diagram of the assembled cement pavement structure of the present invention, figure 2 yes figure 1 Schematic diagram of the cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com