Textile cloth cover unhairing device

A cloth surface and box body technology, applied in the textile field, can solve the problems of oil stains that are difficult to clean, time-consuming and laborious, and the fabric cannot meet the acceptance standards, so as to reduce cleaning dead ends, improve surface quality, and reduce use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention;

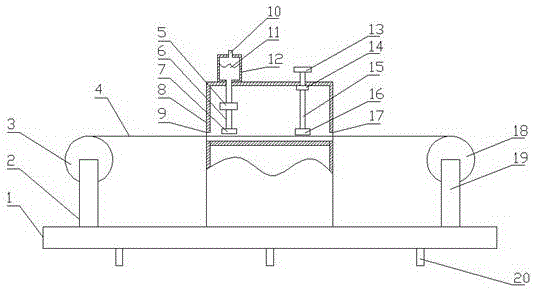

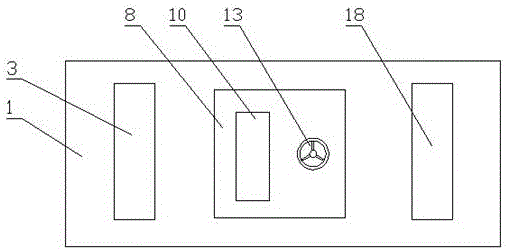

[0022] Such as figure 1 , figure 2 As shown, the cloth surface depilation device for weaving has a structure comprising a chassis 1; the upper surface of the chassis 1 is fixed with a reel 3 via the first support 2, and the reel 3 is used to store the finished cloth 4 during use; One side of the reel 3 is provided with a box 8, the box 8 is a cuboid structure, and the box 8 is used to provide support and protection for related components during use; one side of the box 8 is provided with an electric reel 18 , electric reel 18 is fixed on the upper surface of chassis 1 through second support 19, and electric reel 18 is used for the power that cloth 4 moves forward during use, and the cloth 4 that will remove hair is taken up on the electric reel 18.

[0023] In the above embodiment, specifically, the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com