Method for segment pretreatment on straws through ammonia water and hydrogen peroxide

A hydrogen peroxide and pretreatment technology, applied in the application field, can solve the problems of less than 50% effective utilization rate, difficulty in industrial application, and large consumption of acid and alkali, and achieve the effect of easy industrial utilization, low price, and high equipment utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

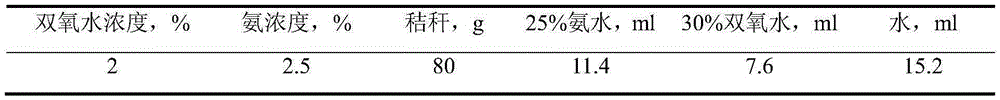

[0023] A method for segmentally pretreating straw by using ammonia water and hydrogen peroxide, comprising:

[0024] Take finely crushed corn stalks (≥200 mesh), add water and ammonia water, mix well, and let stand at 25°C for 24 hours; then add hydrogen peroxide, mix well, put the mixture after adding hydrogen peroxide into water at 20°C exothermic gas), let stand in water for 24h.

[0025] The amount of added water, ammonia, and hydrogen peroxide is calculated according to that the straw content in the final system is 70% (w / w), the ammonia content is 2.5% (w / w), and the hydrogen peroxide content is 2% (w / w).

[0026] The initial concentration of ammonia water added is 25%, and the initial concentration of hydrogen peroxide added is 30%.

[0027] The specific system is as follows:

[0028]

Embodiment 2

[0030] A method for segmentally pretreating straw by using ammonia water and hydrogen peroxide, comprising:

[0031] The method of this embodiment is basically the same as that of Example 1, except that the ammonia content in the final system is 0.5% (w / w), and the hydrogen peroxide content is 1% (w / w). The specific system is as follows:

[0032]

Embodiment 3

[0034] A method for segmentally pretreating straw by using ammonia water and hydrogen peroxide, comprising:

[0035] The method of this embodiment is basically the same as that of Example 1, except that the ammonia content in the final system is 2.5% (w / w), and the hydrogen peroxide content is 3% (w / w).

[0036] The specific system is as follows:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com