Preparation method of spherical bayerite powder with by-production of ammonium nitrate

A technology of ammonium nitrate and aluminum stone powder, which is applied in the direction of ammonium nitrate, chemical instruments and methods, alumina/aluminum hydroxide, etc., can solve the problems of difficult storage, unstable chemical properties of ammonium nitrate, and difficult preparation, and achieve The effect of small powder particle size, high sphericity and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

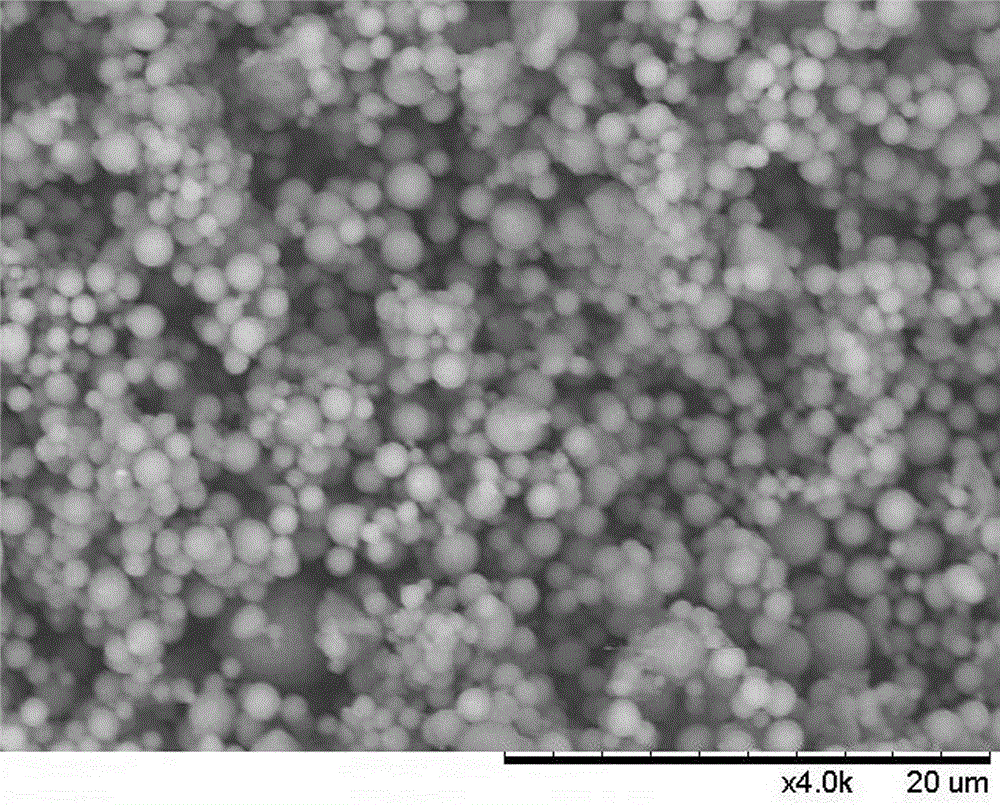

[0029] 100ml of aluminum nitrate solution with a concentration of 0.05mol / L, magnetically stirred, while controlling the temperature at 35°C, adding aluminum nitrate solution dropwise with 20% ammonia water, flocculent precipitation appeared in the reactor, when the pH value of the reaction solution reached At 9.5 o'clock, stop dripping ammonia water, place the reactor in ultrasonic waves, and after ultrasonic vibration for 30 minutes, the reaction liquid becomes a suspension, and the suspension is washed with water and suction filtered several times, and the filtrate is spray-dried to obtain by-product ammonium nitrate, filter cake Diluted with distilled water and ultrasonically oscillated for 20 minutes to become a suspended aqueous solution, and the suspended aqueous solution was spray-dried to obtain spherical bayalite powder (see attached figure 1 ).

Embodiment 2

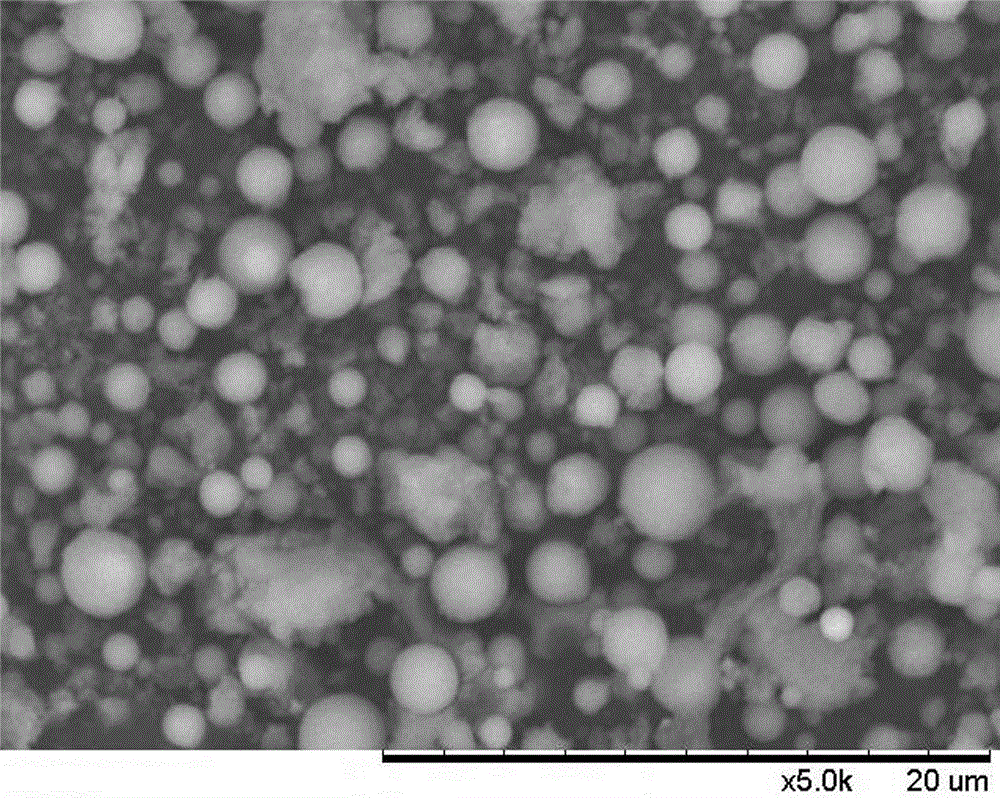

[0031] 100ml of aluminum nitrate solution with a concentration of 0.45mol / L, magnetically stirred, while controlling the temperature at 35°C, dripping aluminum nitrate solution with a concentration of 20% ammonia water, flocculent precipitation appeared in the reactor, when the pH value of the reaction solution reached At 9.5 o'clock, stop dripping ammonia water, place the reactor in ultrasonic waves, and after ultrasonic vibration for 30 minutes, the reaction liquid becomes a suspension, and the suspension is washed with water and suction filtered several times, and the filtrate is spray-dried to obtain the by-product ammonium nitrate, filter cake Diluted with distilled water and ultrasonically oscillated for 20 minutes to become a suspended aqueous solution, and the suspended aqueous solution was spray-dried to obtain spherical bayalite powder (see attached figure 2 ).

Embodiment 3

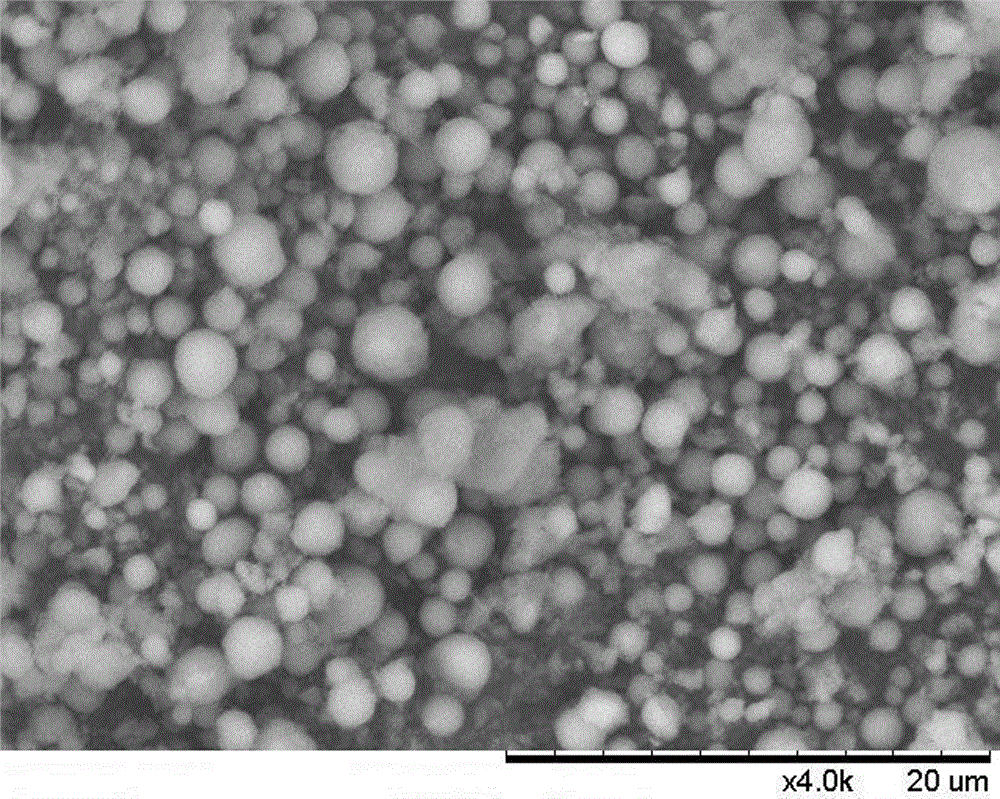

[0033] 100ml of aluminum nitrate solution with a concentration of 0.05mol / L was stirred magnetically, while the temperature was controlled at 45°C, and the aluminum nitrate solution was added dropwise with 20% ammonia water, and flocculent precipitation appeared in the reactor. When the pH value of the reaction solution reached At 9.5 o'clock, stop dripping ammonia water, place the reactor in ultrasonic waves, and after ultrasonic vibration for 30 minutes, the reaction liquid becomes a suspension, and the suspension is washed with water and suction filtered several times, and the filtrate is spray-dried to obtain the by-product ammonium nitrate, filter cake Diluted with distilled water and ultrasonically oscillated for 20 minutes to become a suspended aqueous solution, and the suspended aqueous solution was spray-dried to obtain spherical bayalite powder (see attached image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com