Multistage speed change mechanism of wire harness binding device and speed change method and application of multistage speed change mechanism of wire harness binding device

A technology of speed change mechanism and speed change structure, which is applied in the direction of packaging machine, packaging, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

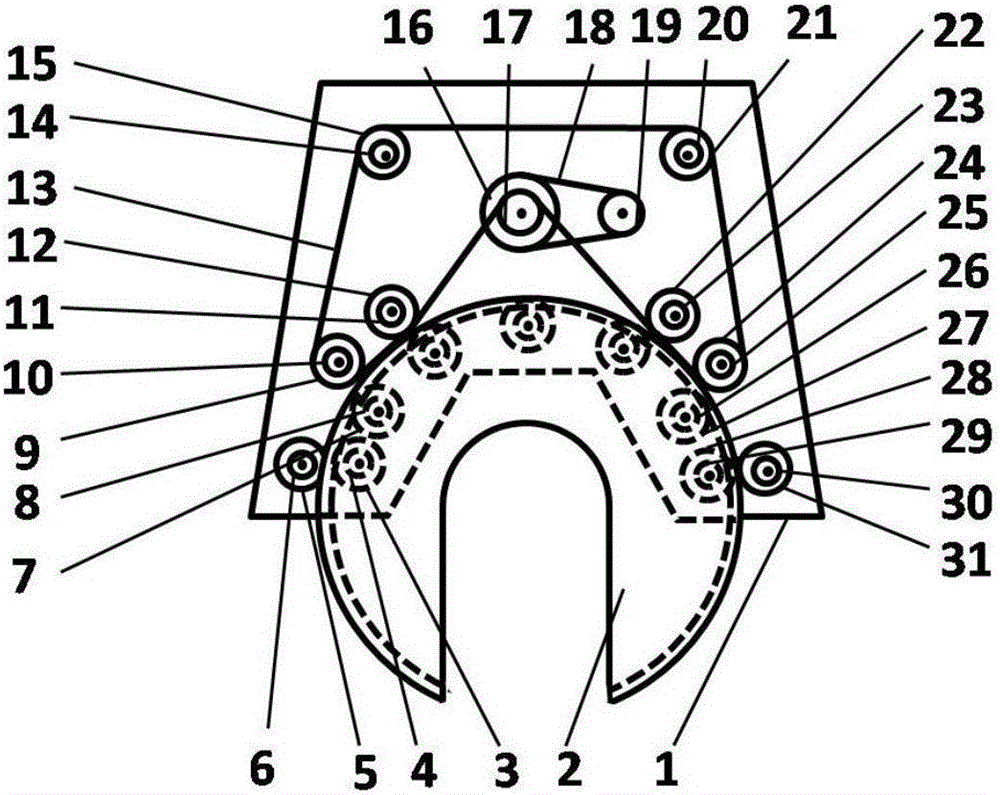

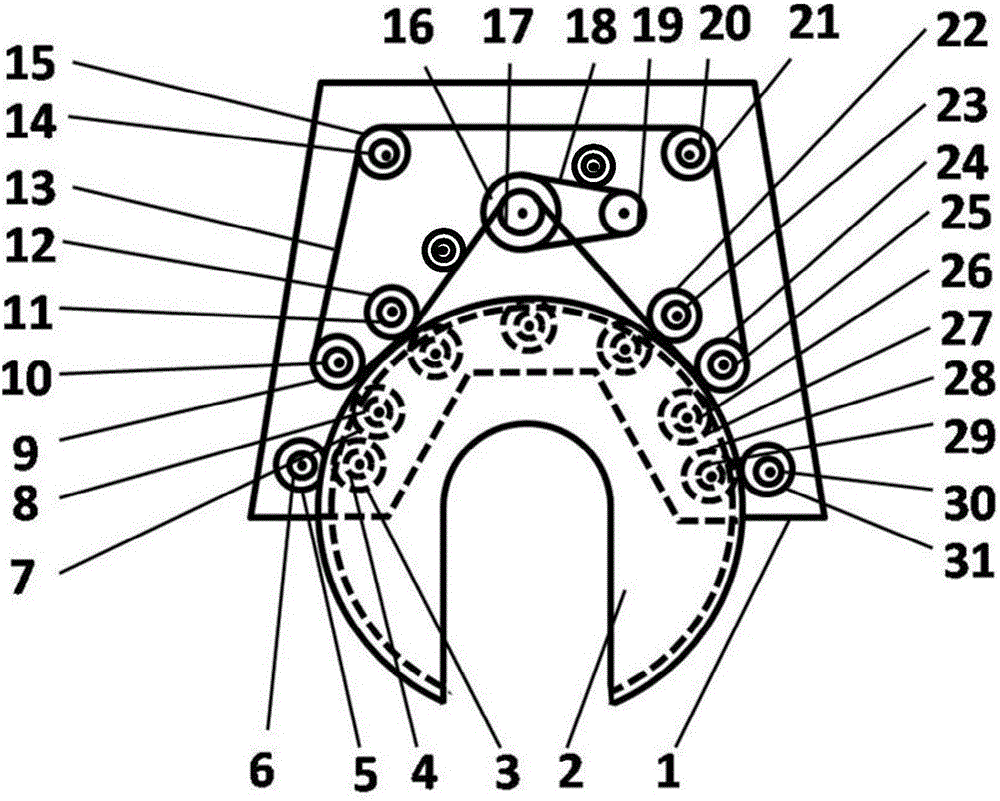

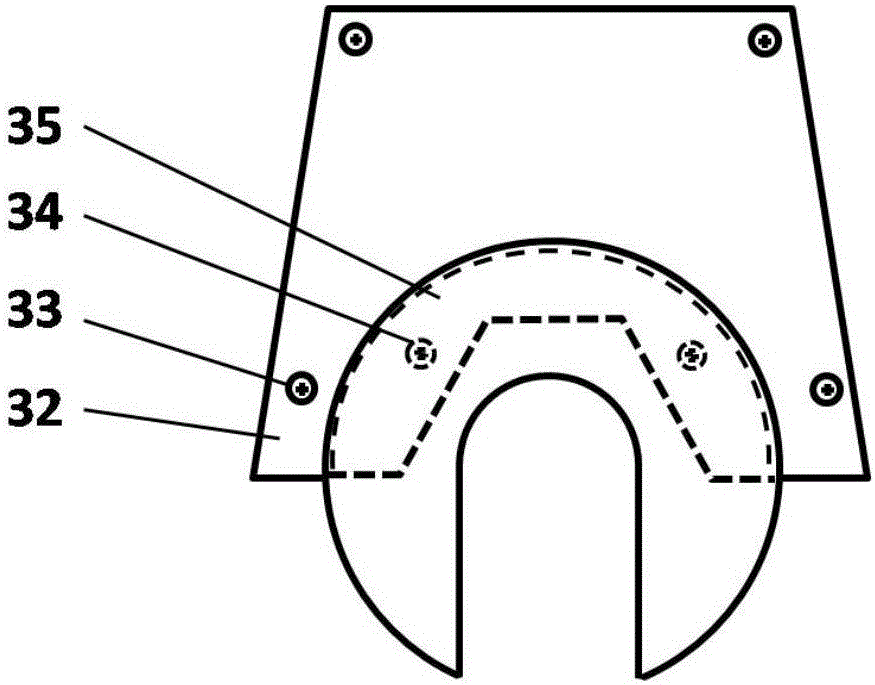

[0054] The present invention will be further described below in conjunction with the accompanying drawings.

[0055] Referring to Figure 1(a), (b) and figure 2 , a multi-stage transmission mechanism for wire harness wrapping equipment, including a gearbox body 1, a rotating body 2, a first inner guide wheel 3, a first inner guide wheel bearing 4, a first outer guide wheel bearing 5, a first outer guide wheel 6. Second inner guide wheel 7, second inner guide wheel bearing 8, second outer guide wheel 9, second outer guide wheel bearing 10, third outer guide wheel 11, third outer guide wheel bearing 12, secondary synchronization Transmission belt 13, first tensioner eccentric bearing 14, first eccentric tensioner 15, primary passive transmission wheel 16, secondary passive transmission wheel 17, primary synchronous transmission belt 18, primary synchronous gear 19, second tensioner Wheel eccentric bearing 20, the second eccentric tensioning wheel 21, the fourth outer guide wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com