Flexible part parallel-clamping and coupling switchover self-adaptive robot finger device

A robot finger, self-adaptive technology, applied in the direction of manipulator, program-controlled manipulator, chuck, etc., can solve the problems of large mechanism, large deformation of multiple spring parts, small grasping range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

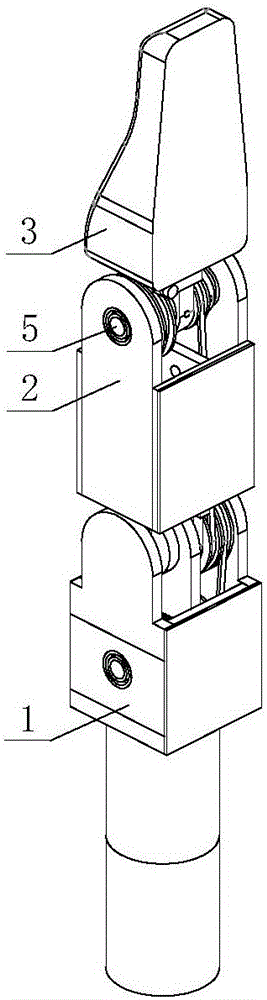

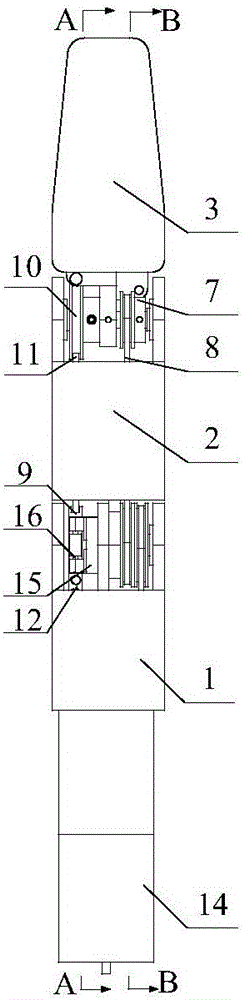

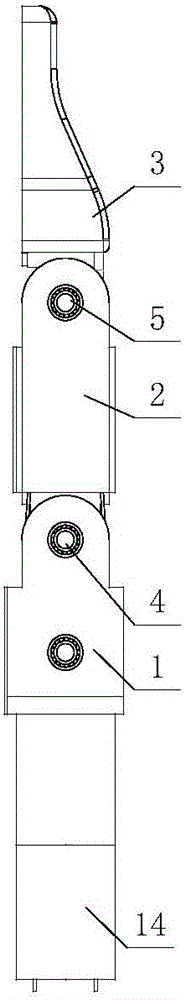

[0044] An embodiment of the flexible piece flat clip coupling switching adaptive robot finger device designed by the present invention, such as Figure 1 to Figure 9 As shown, it includes a base 1, a first finger segment 2, a second finger segment 3, a proximal joint shaft 4, a distal joint shaft 5 and a driver 14; the driver 14 is fixedly connected to the base 1; the proximal joint shaft 4 The centerline of is parallel to the centerline of distal joint axis 5. This embodiment also includes a transmission mechanism, a first transmission wheel 6, a second transmission wheel 7, a flexible transmission member 8, a half wheel 9, a third transmission wheel 10, a tendon rope 11, a half wheel bump 12, and a half wheel connector 15 , rotating shaft 16, first spring 13, second spring 19 and limit project...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com