A fastening type glass column side slotting device

A glass column and fastening technology, which is applied in the direction of grinding drive devices, grinding machines, grinding machine parts, etc., can solve the problems of high price, failure to meet processing requirements, roughness, etc., and achieve simple structure and increase Friction, the effect of increasing the degree of tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be further described in detail below.

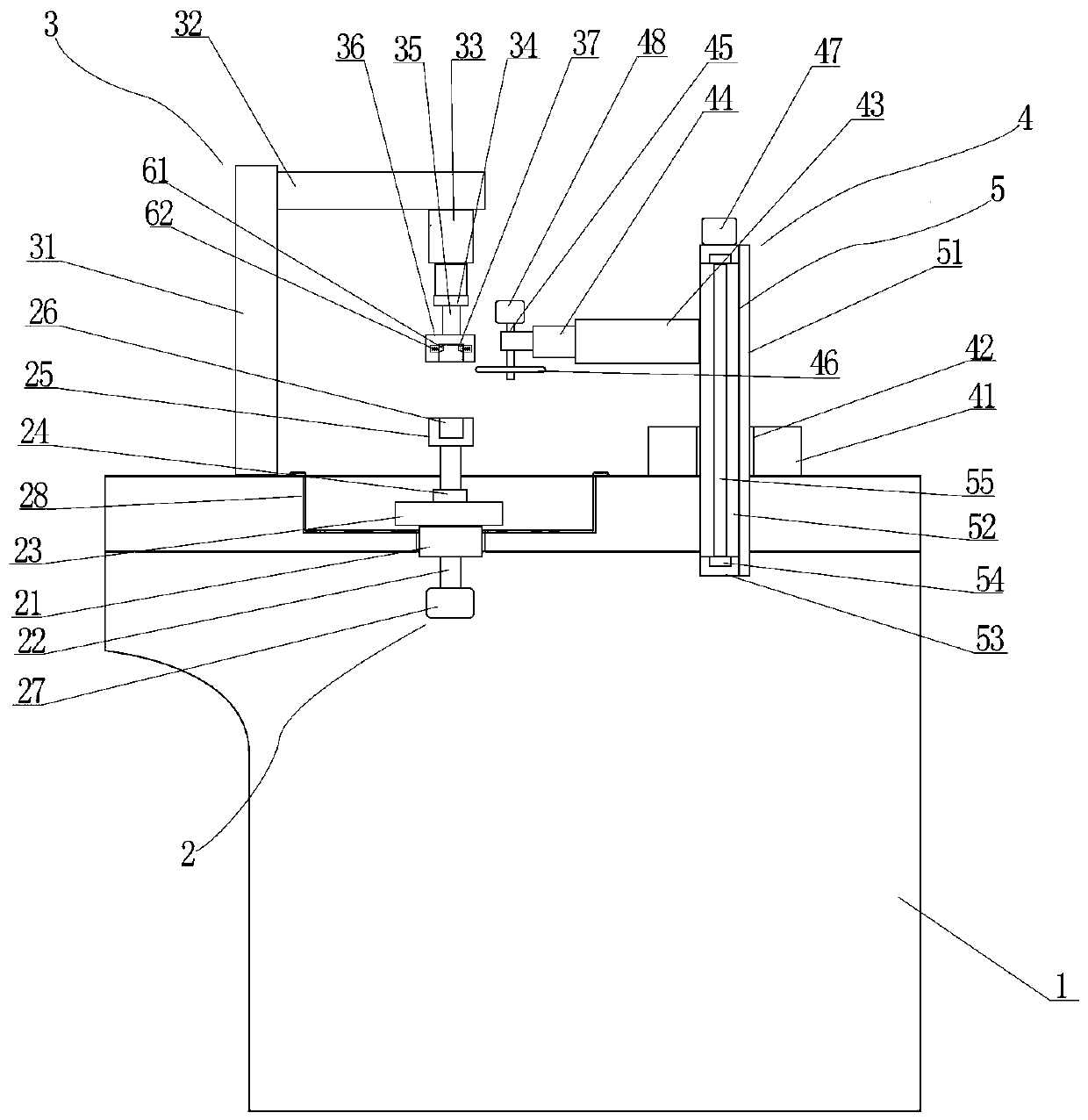

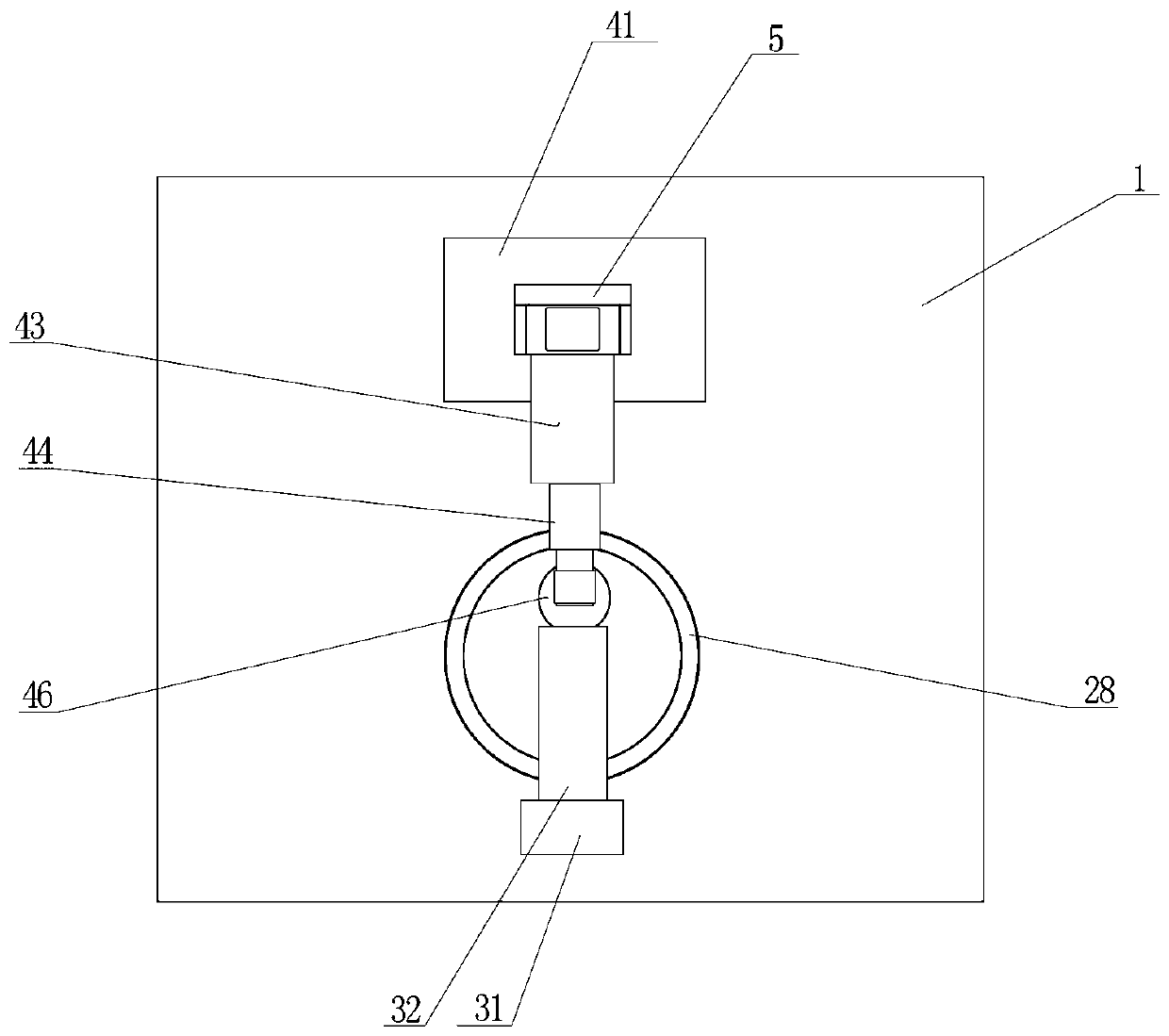

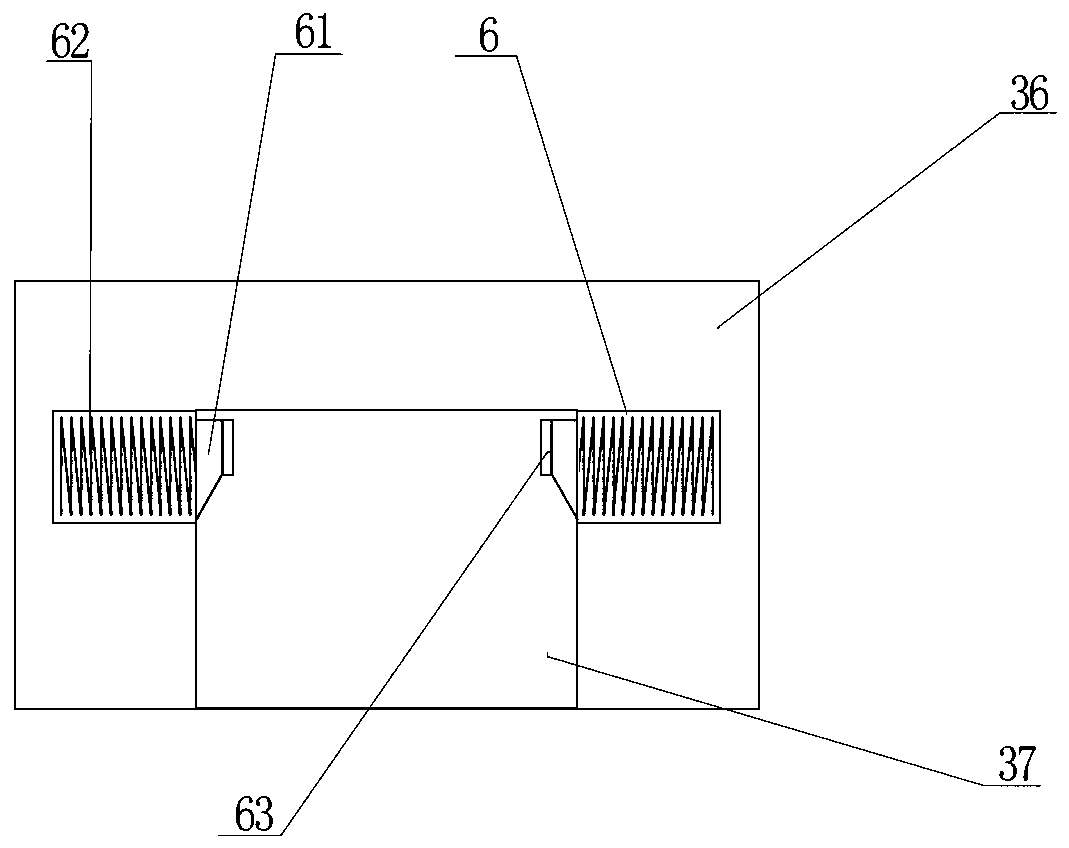

[0016] Such as Figure 1 to Figure 3 As shown, a fastened glass column side grooving device of the present invention includes a frame 1, a rotating assembly 2 is arranged on the frame 1, and a fixing assembly 3 and a grinding assembly 4 are respectively arranged on both sides of the rotating assembly 2 , the grinding assembly 4 includes a support seat 41 arranged on the frame 1, a square groove 42 is provided on the support seat 41, a spiral vertical rod 5 is vertically arranged in the square groove 42, and the spiral vertical rod 5 includes a back plate 51, the back plate 51 The left and right sides of the back plate 51 are respectively provided with a side plate 52, the upper and lower ends of the back plate 51 are respectively provided with a support block 53 horizontally, the support block 53 is provided with a first bearing 54, and a wire rod is vertically arranged between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com