Split mounting-type alloy steel frog working edge and rail top integral special-purpose milling cutter

A technology of alloy steel and working edge, which is applied in milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive processing, and achieve the effects of saving processing cost, reducing impact and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

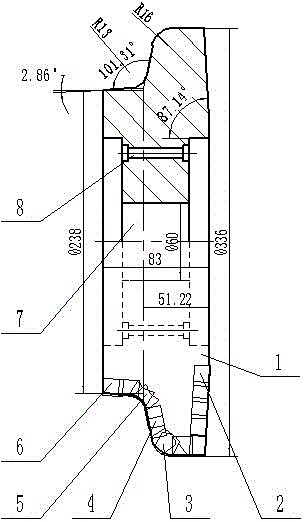

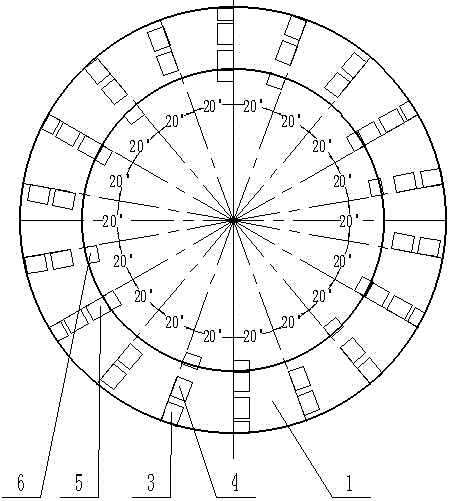

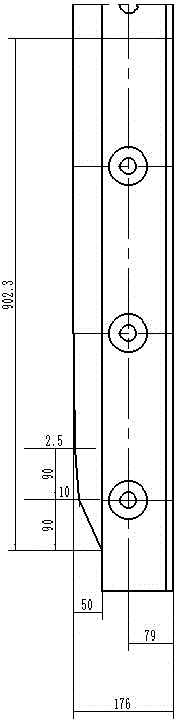

[0017] An assembled alloy steel frog working side and rail top integral special milling cutter, such as figure 1 —— figure 2 As shown, its structure is as follows: the front end of the milling cutter head 1 is round cake-shaped, and the rear end is cylindrical. The thickness is 83mm, and there is a mounting hole 7 in the middle of the milling cutter head 1. Several light holes 8 that can be installed with bolts are evenly distributed on the outside of the mounting hole 7; at one end of the diameter, it is from the edge of the mounting hole 7 to the edge of the round cake. The angle of inclination is 87.14°, the rear end of the round cake is inclined 101.31° to the inner side of the round cake, the inclined surface of the front end of the milling cutter head 1 is radially equipped with an array of flat blade groups 1 and 2, and the outer edge is aligned with the rear of the round pie. There is an R16 outer arc blade 3 at the junction of the ends, and a flat blade group 2 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com