Carrying method of broadside structural bodies

A structure and side-side technology, which is applied to ship components, ships, transportation and packaging, etc., can solve the problems of dumping and deformation of the side-side structure in the cargo area with large openings, and achieve easy construction accuracy, reduce construction deformation, and improve construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation examples in order to express the structural features and specific applications of the present invention more clearly, but this should not limit the protection scope of the present invention.

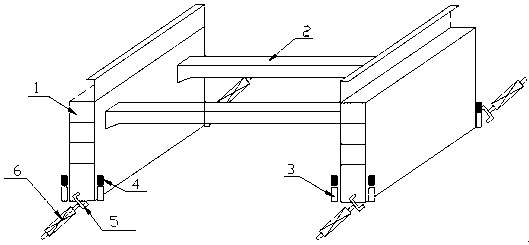

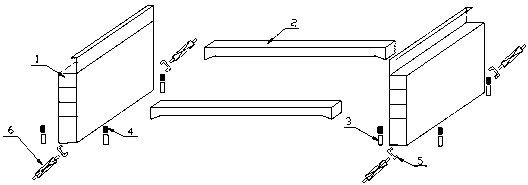

[0019] Such as figure 1 with figure 2 As shown, the carrying method of the side structure of the present embodiment includes the following steps:

[0020] The first step is to position the side structures. The cranes are used to position the two side structures. The two side structures are placed parallel to each other. The relative dimensions of the two side structures 1 are ensured through positioning. The location mainly refers to the front and rear end faces of the two structures 1 having the same planarity ≤ 5mm, the height synchronization ≤ 5mm, and the front and rear width spacing conforming to the tolerance requirements of the design d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com