A method for mounting a side structure

A structure and broadside technology, applied in ship construction, ships, and ship parts, etc., can solve problems such as tipping and deformation of the broadside structure in the cargo hold area with large openings, and achieve easy construction accuracy, avoid resources, and save the second use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following describes the present invention in further detail with reference to the accompanying drawings and specific implementation cases, in order to express the structural features and specific applications of the present invention more clearly, but the protection scope of the present invention should not be limited by this.

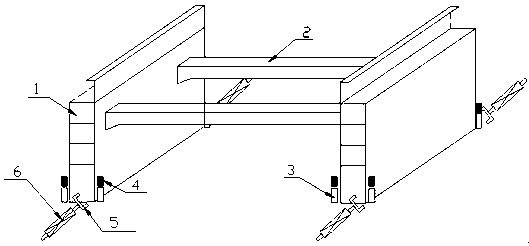

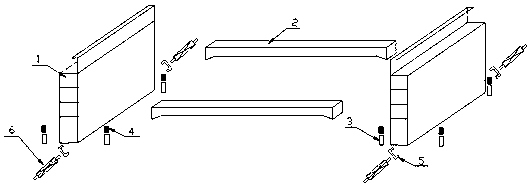

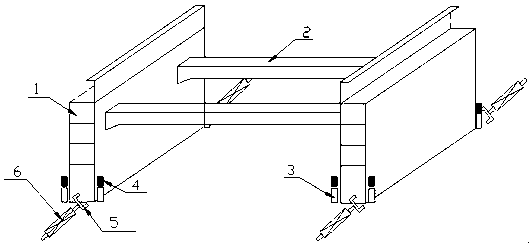

[0019] Such as figure 1 with figure 2 As shown, the method for loading a side structure in this embodiment includes the following steps:

[0020] The first step is to locate the side structure. A crane is used to position the two side structures. The two side structures are placed parallel to each other. The positioning ensures the relative size of the two side structures 1. The position mainly refers to the same plane degree of the front and rear ends of the two structures 1 ≤5mm, height synchronization ≤5mm, the front and rear width spacing is consistent with the tolerance requirements of the design drawings, generally ≤6mm, the two side struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com