Method for forging workblank of transmission disc of locomotive

A technology of drive discs and blanks, applied in the directions of wheels, vehicle parts, transportation and packaging, etc., can solve problems such as low production efficiency, reduced service life of machine drive discs, and increased man-hours and costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

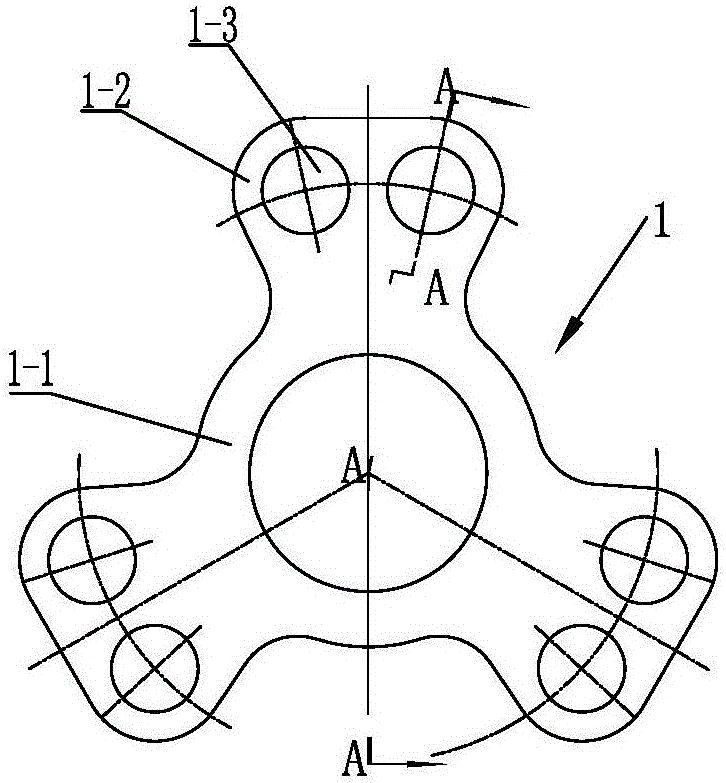

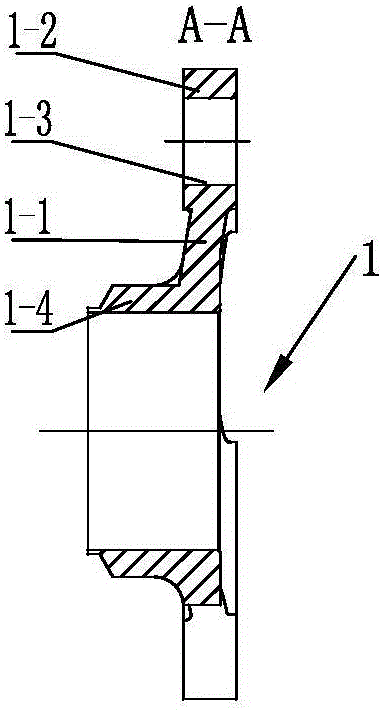

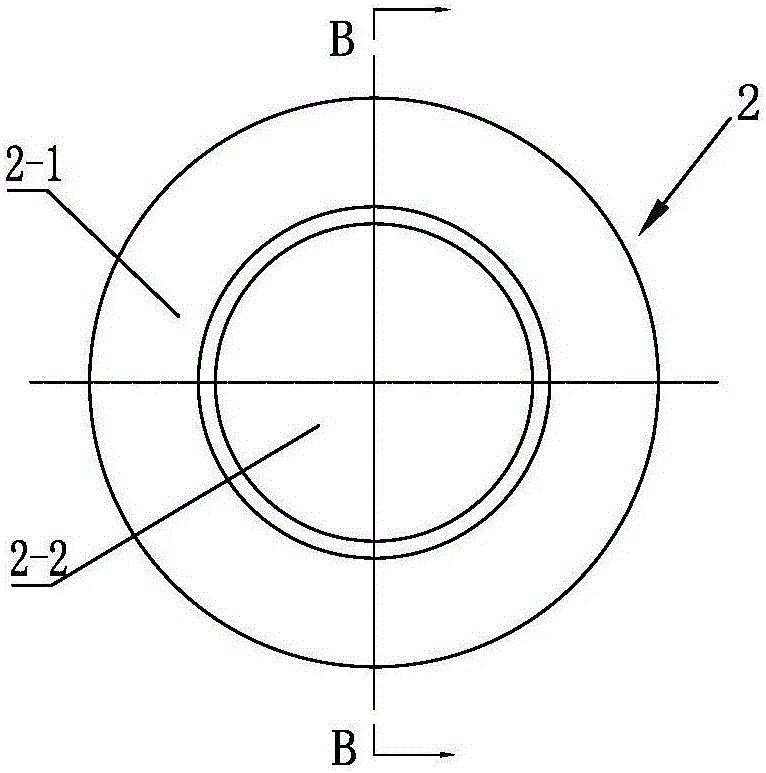

[0039] See Figure 5 Shown, the method for forging locomotive transmission plate blank of the present invention, carries out according to the following steps.

[0040] ⑴, blanking.

[0041] Select the raw material of the required material, such as carbon steel or alloy steel, and cut the blank 3 according to the weight. Figure 6 The blank 3 shown can greatly improve the utilization rate of raw materials.

[0042] ⑵, heating.

[0043] Put the billet 3 into the heating furnace and heat it to 1100°C-1180°C to reduce the yield stress of the billet after heating. Forging and final forging are formed, and the three ear parts 7-1 of the forging blank can be formed full, so that the dimensions of the forging blank can be stabilized within the tolerance range.

[0044] ⑶ Pre-forging.

[0045] The pre-forging of the present invention adopts the combination of open forging die and free forging. See Figure 7-11 As shown, the heated blank 3 is put into the lower cavity of the pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com