Chain belt type plate pulling machine

A chain belt type, trigger technology, applied in the field of plate processing, can solve the problems of discontinuous force, damage deformation, unevenness of the plate, etc., to achieve the effect of saving work space, continuous tension, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

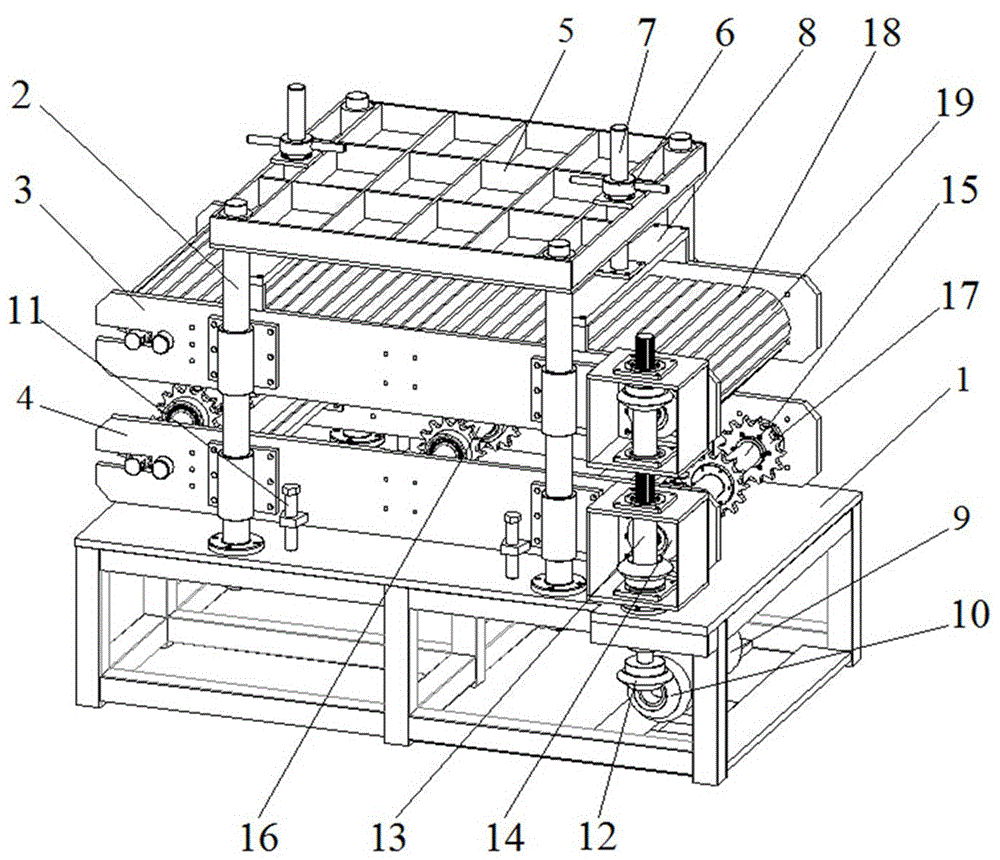

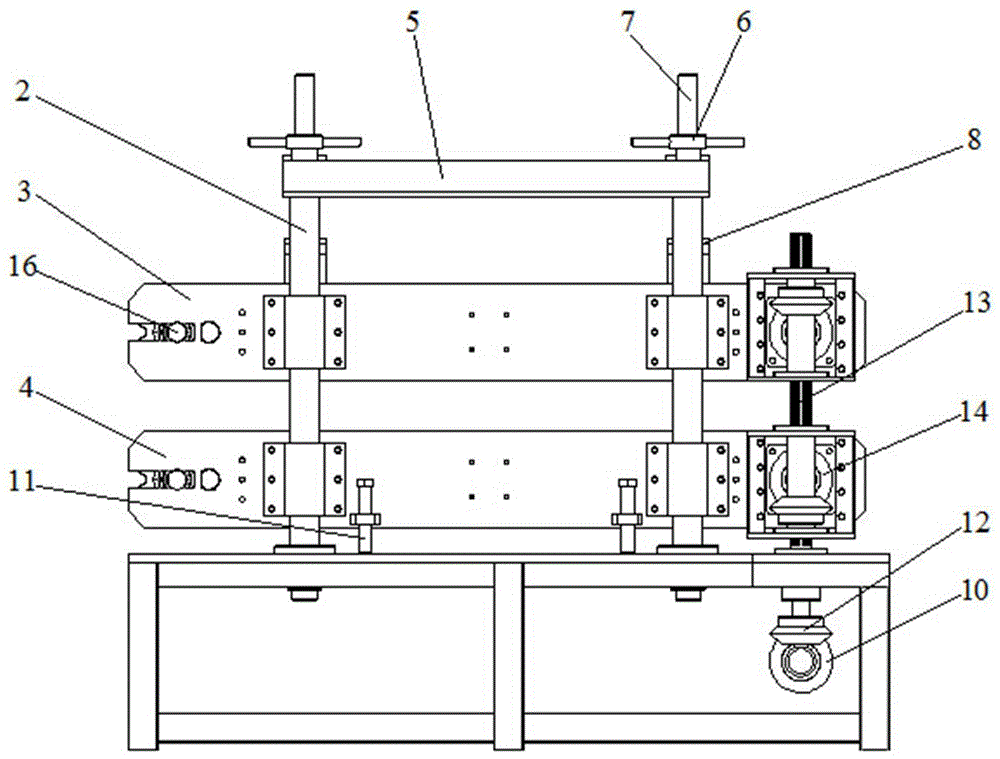

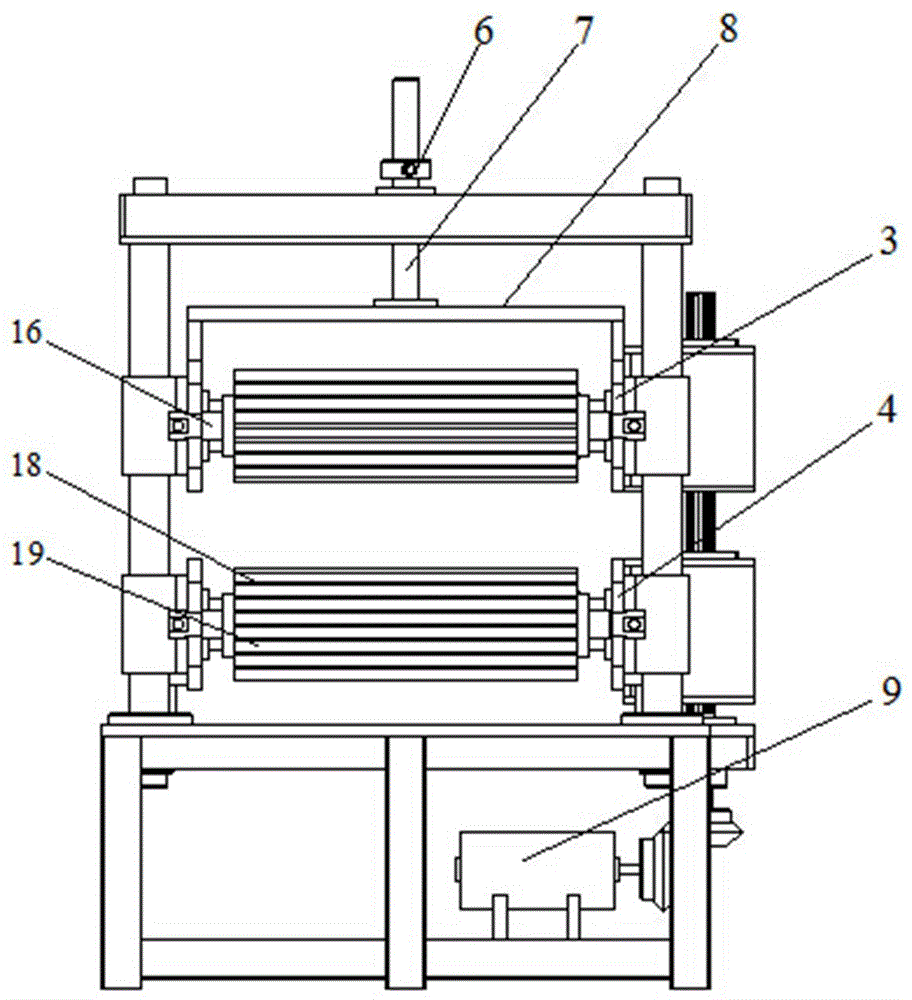

[0024] Such as figure 1 As shown, a chain belt type drawing machine includes a machine base 1, 4 guide rods 2, an upper pressure roller frame 3, a lower pressure roller frame 4, an upper bracket 5, 2 handles 6, 2 screw rods 7, 2 lifting frames 8, motor 9, motor helical gear 10, 4 positioning screws 11, 3 transmission rod helical gears 12, transmission rod 13, 2 power shaft helical gears 14, 2 power shafts 15, 4 rotating shafts 16 , 18 chain pulleys 17, 2 chain belts 18, several rubber pressing blocks 19.

[0025] The lower ends of the four guide rods 2 are vertically fixed on the machine base 1, the upper ends are fixedly connected with the upper bracket 5, and the middle ends are movably connected with the lower roller frame 4 and the upper roller frame 3 from bottom to top.

[0026] The lower pressure roller frame 4 is positioned on the machine base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com