Sphere coating machine

A coating machine and coating technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of difficult control of depth and time, uneven color of small balls, low coating yield, etc., to achieve guaranteed The effect of coating, uniform specification and uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

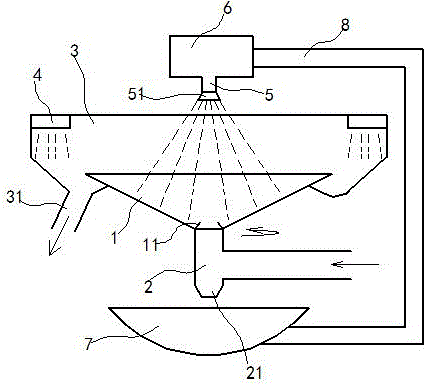

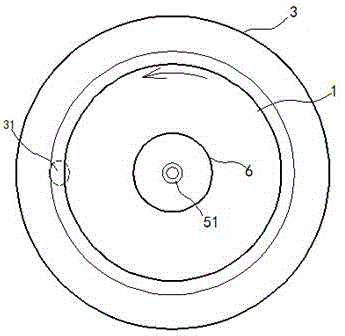

[0015] exist figure 1 , figure 2 In the shown embodiment, this small ball coating machine includes a coating bowl 1, a goal tube 2 and a ball cover 3; the coating bowl 1 is driven by a drive motor, and the coating bowl 1 can The axis rotates; the bowl wall of the coating bowl 1 is made of hard mesh material, and the bowl wall of the coating bowl 1 is made of electric heating wires, and the electric heating wires are electrically connected to the circuit; the goal tube 2 is connected with the bottom of the coating bowl 1 through a bearing, and the coating bowl 1 can rotate freely relative to the goal tube 2; flow ring edge 11; a diversion hole 21 is opened on the goal tube 2, and the diversion hole 21 is located directly below the bottom of the coating bowl 1; the ball collecting cover 3 is sleeved on the coating The outer periphery of the bowl 1, the ball collecting cover 3 is fixed on the body of the small ball coating machine; a ball outlet pipe 31 is installed on the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com