Piezoelectric two-phase flow ultrasonic atomization spraying nozzle

A technology of ultrasonic atomization and two-phase flow, which is applied to spray devices, liquid spray devices, etc., can solve the problems of large atomization, low power consumption, fine particle size, etc., and achieve the effect of uniform droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

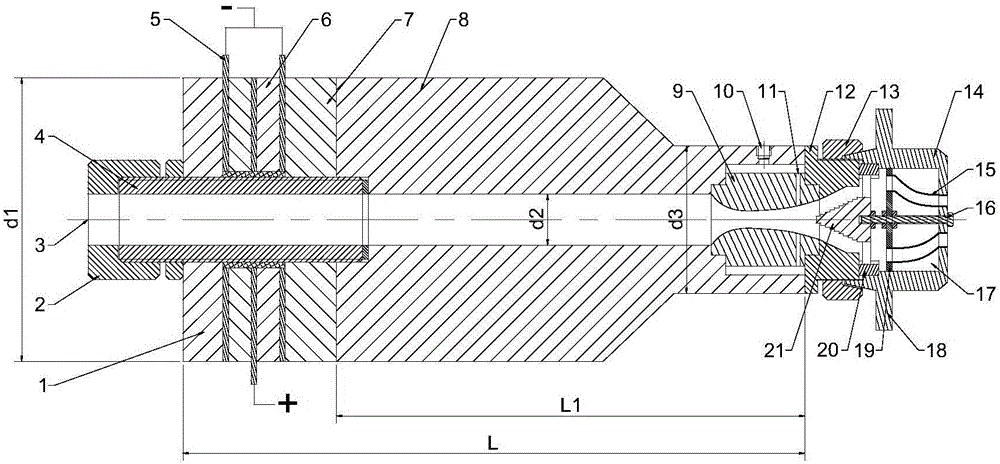

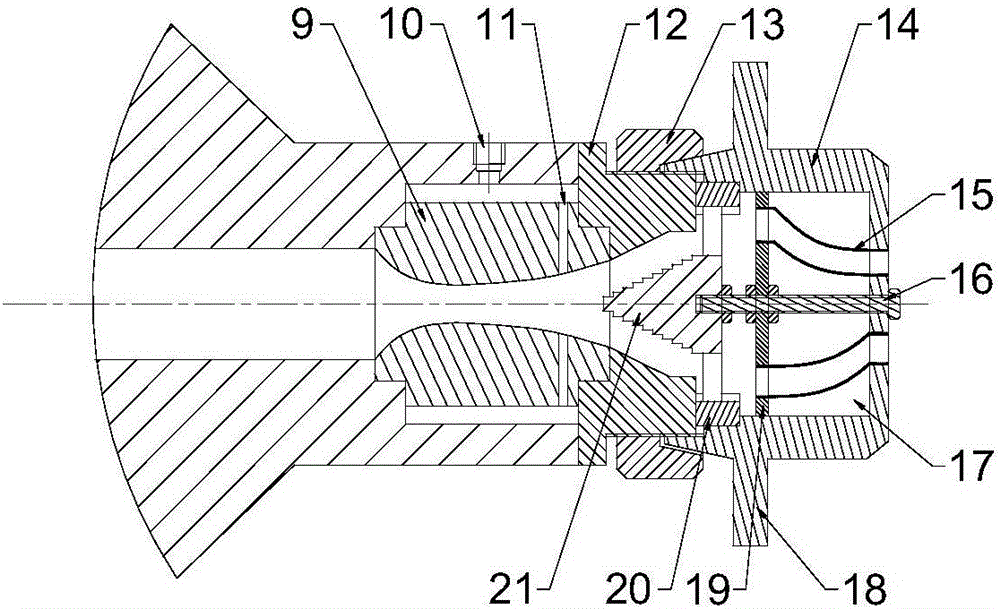

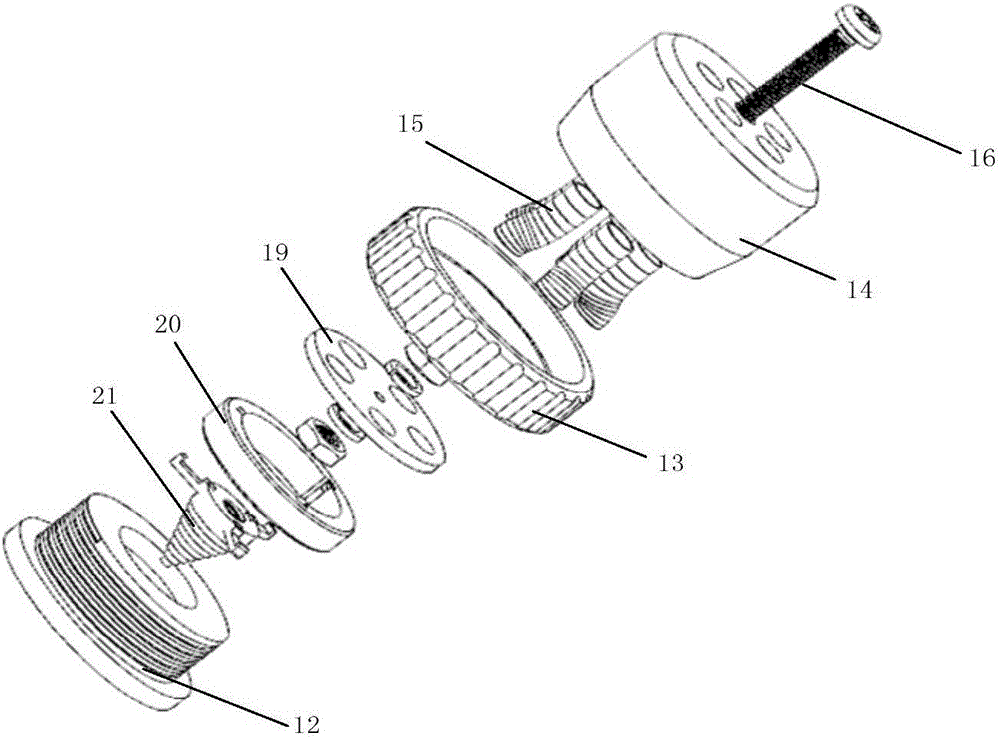

[0028] Such as figure 1 and figure 2 As shown, a piezoelectric two-phase flow ultrasonic atomizing nozzle includes an air inlet joint 2, a connecting bolt 4, a piezoelectric vibrator 6, a horn 8, a Laval valve core 9, a stepped cone valve 21, a Two end caps 12 and a first end cap 14; the piezoelectric vibrator 6 and the horn 8 are fixedly connected through a hollow connecting bolt 4; the tail of the connecting bolt 4 is connected to the air inlet joint 2; the horn 8. The front end is fixedly connected to the second end cover 12 with metal glue. The horn 8 is a stepped horn with a conical transition surface, and the material is duralumin 7075; the length L1 of the horn 8 is a wavelength of sound waves on the horn 8, that is, 66mm, and the horn The diameter of the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com