Semipermeable membrane manufacturing method and semipermeable membrane

A manufacturing method and technology of semi-permeable membranes, applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of water permeability reduction, salt retention, osmotic pressure reduction, etc., and achieve sufficient strength and good semi-permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0113] Hereinafter, the present invention will be described in further detail through examples, but the present invention is not limited by these examples. Various modifications and corrections are possible without departing from the technical scope of the present invention.

[0114] 1. Membrane formation conditions and water permeability

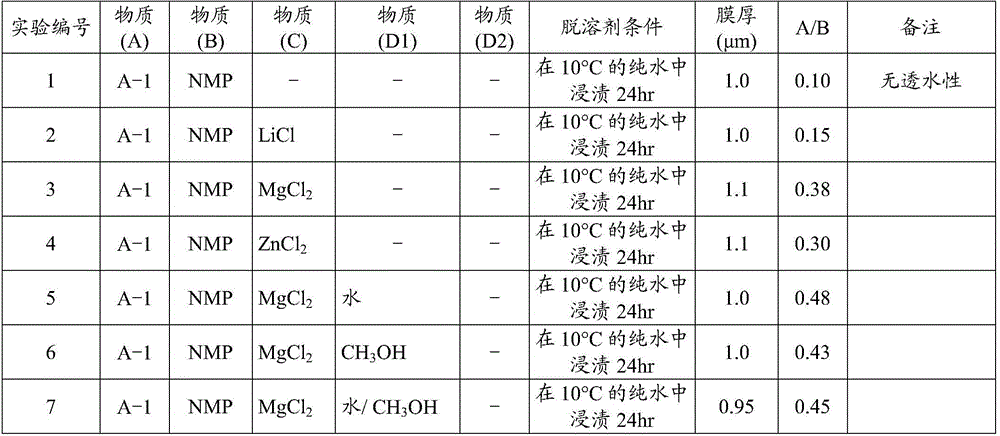

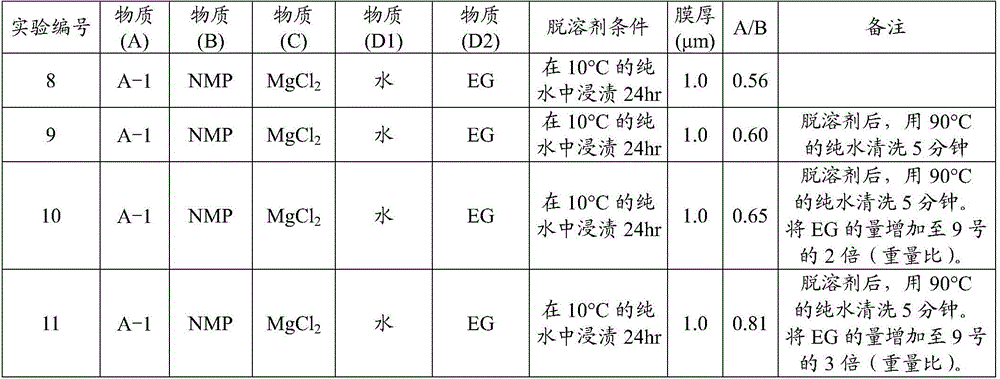

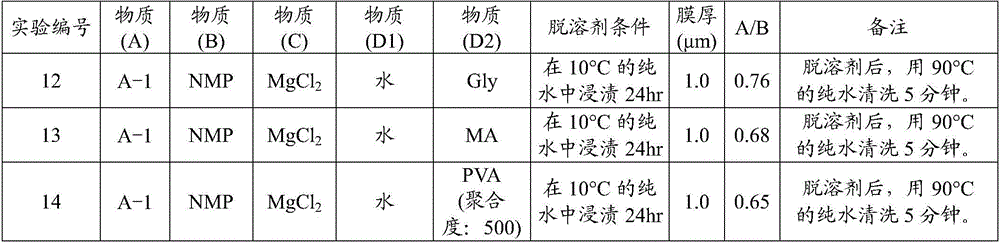

[0115] The membrane-making conditions, membrane structure parameters, and performance values obtained through water permeability tests are listed in Tables 1 to 7. The chemical structure of substance (A) is organized in Table 8. Regarding the mixing ratio of substances (A) to (D), unless otherwise specified in the remarks column of Table 1, in all experiment numbers in Table 1, they are unified as (A) / (B) / (C) / (D1) / (D2)=15 / 60 / 10 / 10 / 5 (weight ratio). It should be noted that both D1 and D2 belong to the substance (D).

[0116] In addition, although substances A-6-A-10 do not correspond to the definition of the said substance (A), they a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com