Collagen-fibroin co-assembly sponge material, co-assembly artificial skin and preparation method of sponge material and co-assembly artificial skin

一种人工皮肤、共组装的技术,应用在组织再生、涂层、医药科学等方向,能够解决人工皮肤降解周期难以控制、真皮层多孔结构杂乱、多孔结构不规则等问题,达到提高愈合质量、促进创面愈合、良好生物相容性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

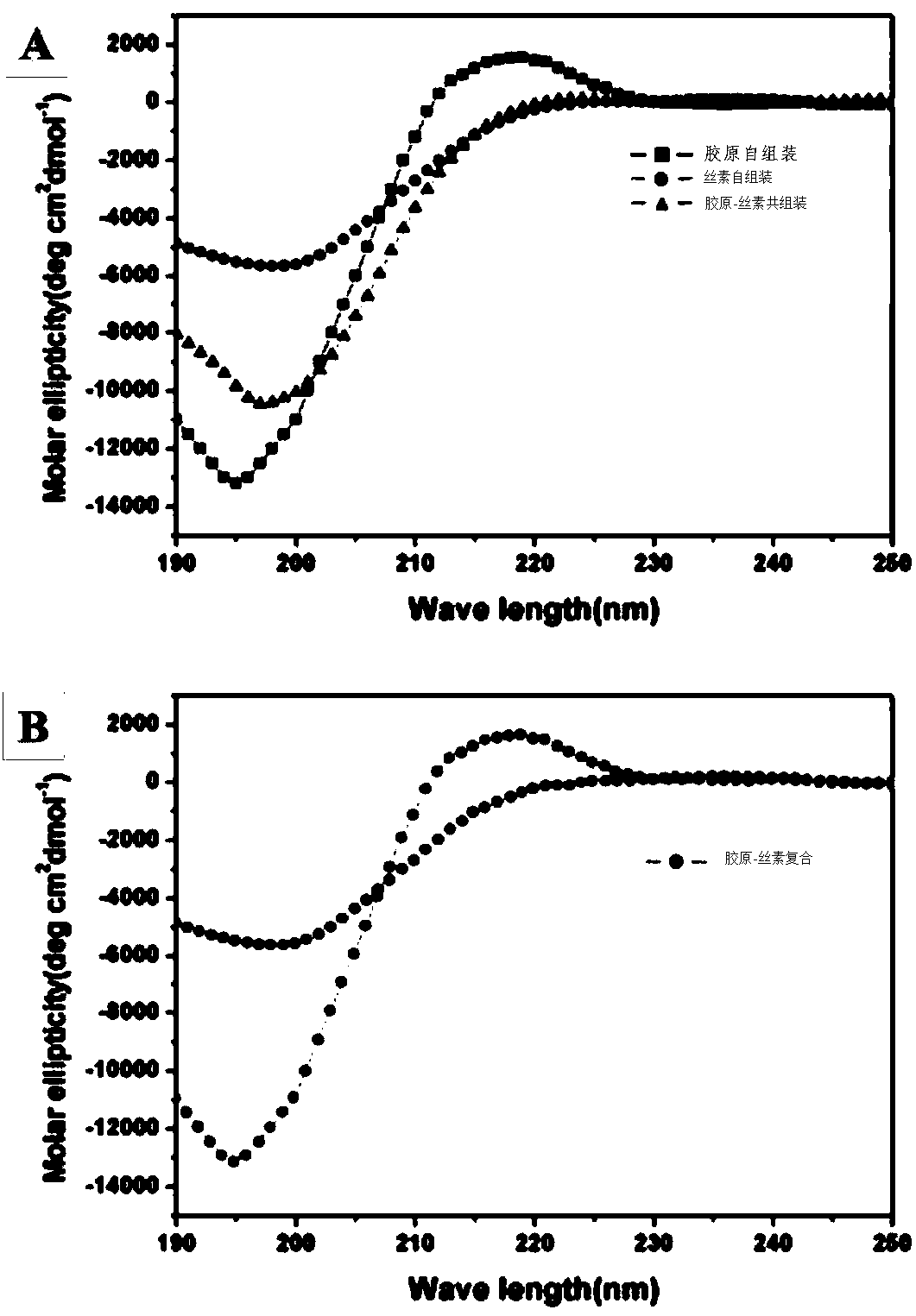

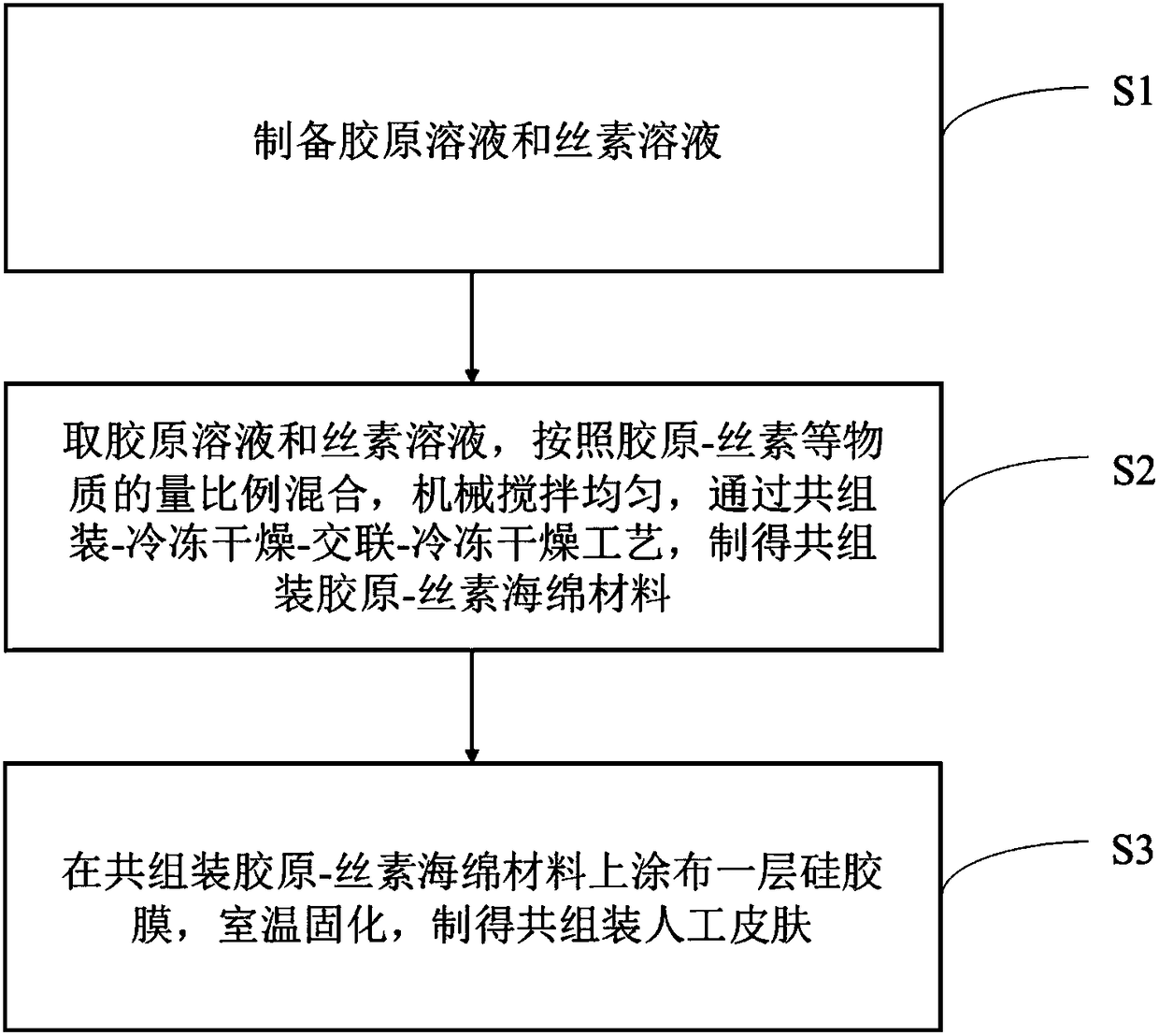

[0039] (1) Weigh an appropriate amount of atelopeptide type I collagen, and prepare a collagen solution with a concentration of 2.5 μmol / L with 0.5 mol / L acetic acid solution. Weigh an appropriate amount of silkworm silk fibroin freeze-dried powder, dissolve it in a calcium chloride ternary system solution (calcium chloride: ethanol: water molar ratio 1:2:8), and dialyze with pure water in a dialysis bag with a molecular weight cut-off of 3500Da. Prepare a silk fibroin solution with a concentration of 2.5 μmol / L.

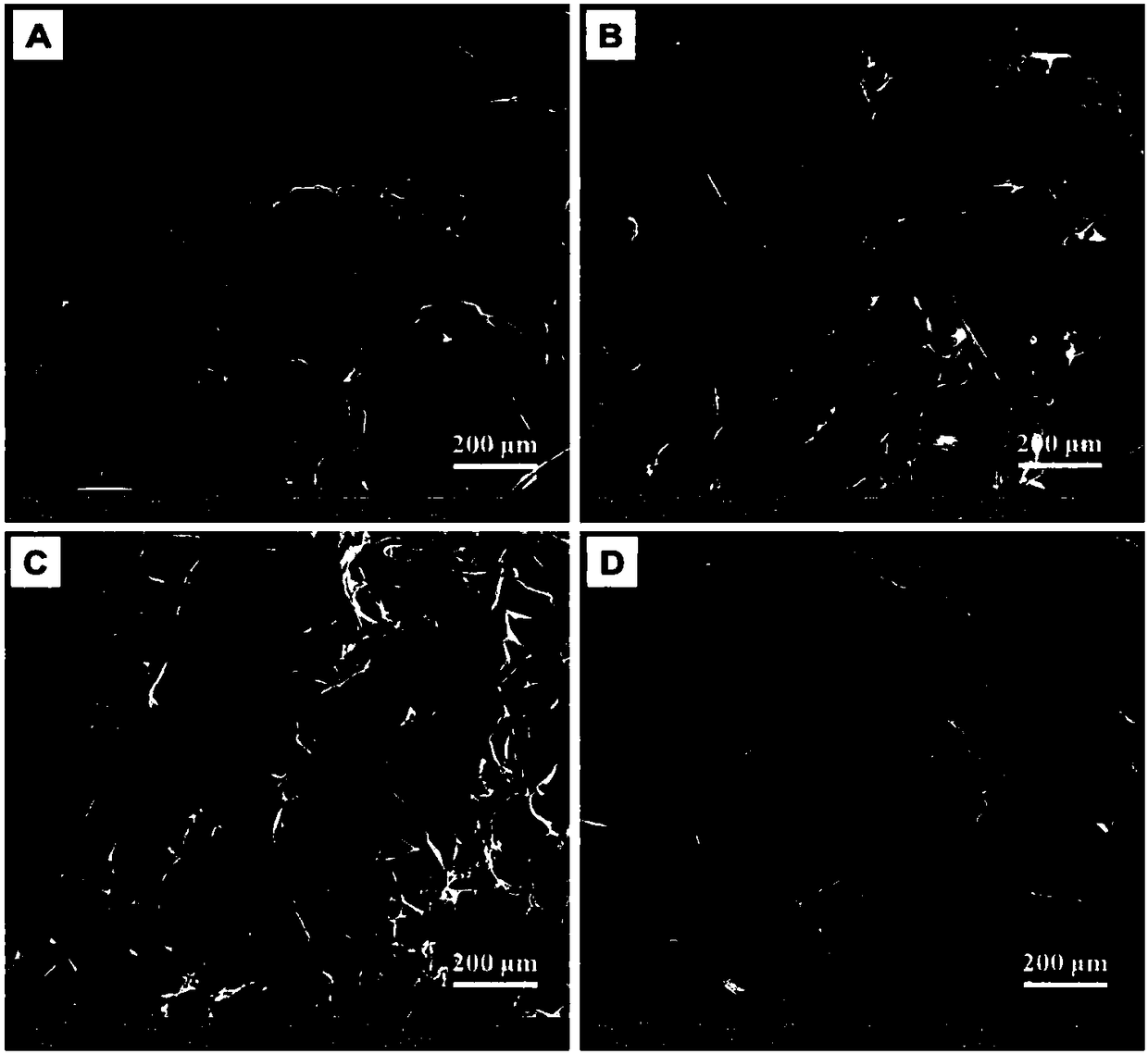

[0040] (2) Take 2.5 μmol / L collagen solution and 2.5 μmol / L silk fibroin solution, mix them in equal volumes, stir them mechanically at 200 rpm and 0°C for 8 hours, and then mix them under the conditions of 0°C and 40% humidity Co-assembled for 48 hours (collagen-silk fibroin co-assembled product), the mixed solution after co-assembly was frozen at four temperature points of 0°C, -20°C, -40°C, and -80°C for 12h respectively, and then at -80°C , Dry under 1Pa condit...

Embodiment 2

[0055] (1) Weigh an appropriate amount of atelopeptide type I collagen, and prepare a collagen solution with a concentration of 5.0 μmol / L with 0.5 mol / L acetic acid solution. Weigh an appropriate amount of silkworm silk fibroin freeze-dried powder, dissolve it in a calcium chloride ternary system solution (calcium chloride: ethanol: water molar ratio 1:2:8), and dialyze with pure water in a dialysis bag with a molecular weight cut-off of 3500Da. Prepare a silk fibroin solution with a concentration of 5.0 μmol / L.

[0056] (2) Take 5.0 μmol / L collagen solution and 5.0 μmol / L silk fibroin solution, mix them in equal volumes, mechanically stir for 4 hours under the conditions of rotating speed 150 rpm and temperature 20°C, and then mix them under the conditions of temperature 20°C and humidity 60%. The mixed solution was frozen at four temperature points of 0°C, -20°C, -40°C, and -80°C for 24h, and then dried at -80°C and 1Pa for 60h. The obtained freeze-dried product was cross-...

Embodiment 3

[0059] (1) Weigh an appropriate amount of atelopeptide type I collagen, and prepare a collagen solution with a concentration of 10.0 μmol / L with 0.5 mol / L acetic acid solution. Weigh an appropriate amount of silkworm silk fibroin freeze-dried powder, dissolve it in a calcium chloride ternary system solution (calcium chloride: ethanol: water molar ratio 1:2:8), and dialyze with pure water in a dialysis bag with a molecular weight cut-off of 3500Da. Prepare a silk fibroin solution with a concentration of 10.0 μmol / L.

[0060] (2) Take 10.0 μmol / L collagen solution and 10.0 μmol / L silk fibroin solution, mix them in equal volumes, mechanically stir for 1 hour under the conditions of rotating speed 100 rpm and temperature 37°C, and then mix them under the conditions of temperature 37°C and humidity 80%. The combined solution was assembled at 0°C, -20°C, -40°C, and -80°C for 36 hours, and then dried at -80°C and 1 Pa for 72 hours. The obtained freeze-dried product was cross-linked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com