Cladding light stripper for optical fiber lasers and making method thereof

A fiber laser, cladding light stripping technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of limiting the performance of cladding light strippers and high temperature, achieve efficient and uniform stripping, improve capacity, avoid hot spot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

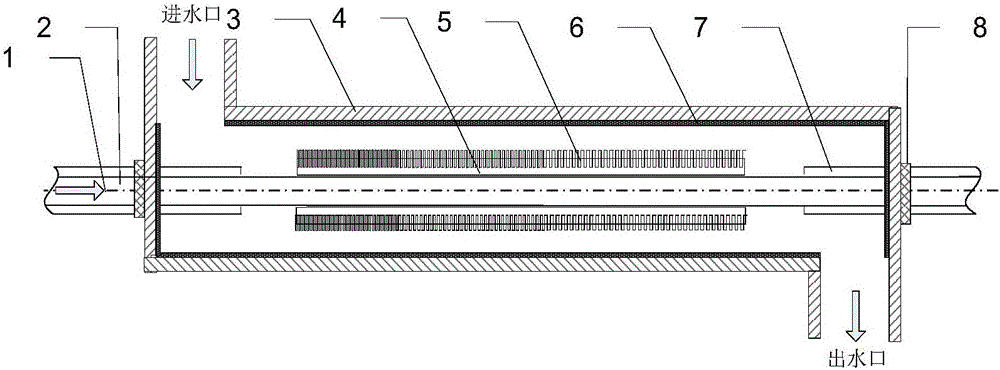

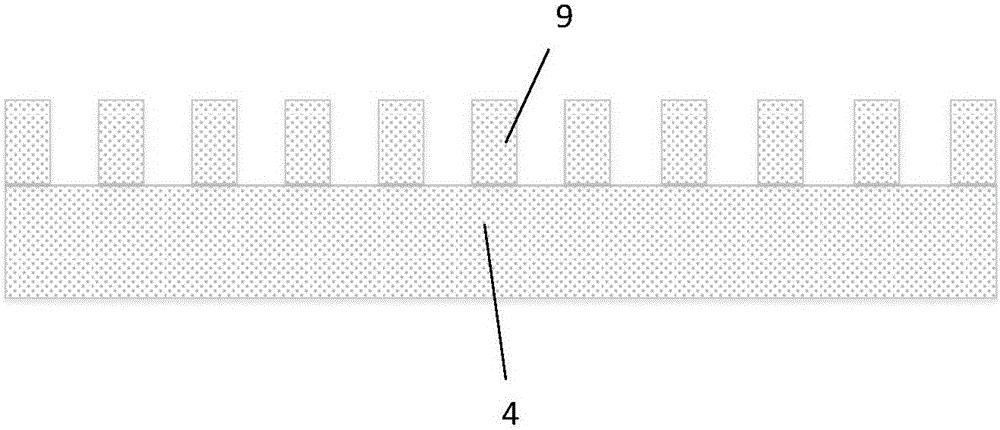

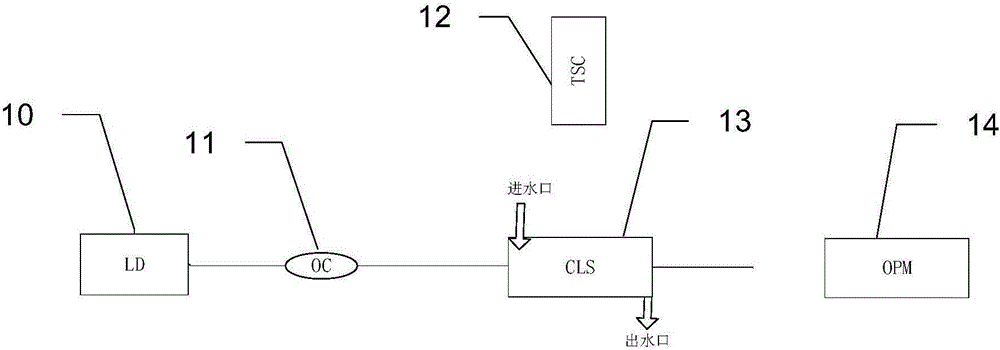

[0036] Example: figure 2It is an embodiment figure of the double-clad optical fiber inner cladding optical stripper of the present invention, as shown in the figure, the present invention is applied to the output end of a high-power fiber laser, and the core diameter of the double-clad optical fiber 13 adopted is 20 μm, The inner cladding is 400 μm. 100 watts of laser light with a wavelength of 915nm emitted by the semiconductor laser assembly 11 is coupled into the double-clad optical fiber 13 through the optical coupler 12, and the inner cladding light is stripped out by the prepared cladding light stripper 15, and the metal tube mouth is connected with Cooling water at 20°C, with a flow rate greater than 1 liter / min, cools the cladding light stripper, and monitors the entire process with a thermal camera 14 and a power detector 16 . Experiments show that the double-clad fiber cladding light stripper does not overheat, the temperature does not exceed 40°C, most of the clad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com