Method for increasing cycle life of lithium ion battery based on thermal conductivity

A lithium-ion battery, cycle life technology, used in battery electrodes, secondary battery repair/maintenance, circuits, etc., can solve the problems of uneven current distribution, large size, and uneven battery temperature, and reduce the internal temperature of the battery. Uneven, simple and easy to implement, the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Weigh lithium manganate LiMn 2 o 4 915g, PVDF45g, conductive carbon black SP and conductive graphite KS15 20g in total, carbon nanotubes (CNTS) 20g, put the weighed material in a high-temperature vacuum oven at 100°C for overnight baking, and set aside.

[0029] 2) Add PVDF to the solvent NMP (Nitromethylpyrrolidone) for gluing.

[0030] 3) Put the materials dried in 1) and the glue beaten in 2) into a planetary vacuum mixer, and carry out vacuum stirring for 3-5 hours to form a uniform slurry.

[0031] 4) Sieve the uniformly mixed slurry, and measure the slurry fineness and viscosity.

[0032] 5) The slurry is coated on the front and back sides on the coating machine.

[0033] 6) Trim and remove the edges of the coated pole pieces, and place them in a vacuum oven for baking.

[0034] 7) Roll the baked pole piece, and then perform final cutting according to the design size of the lithium-ion battery flexible package.

[0035] 8) Take a sample of the cut positive...

Embodiment 2

[0040] 1) Weigh lithium manganate LiMn 2 o 4 915g, PVDF45g, conductive carbon black SP and conductive graphite KS15 total 20g, graphene 20g, bake the weighed material in a high-temperature vacuum oven at 100°C for one night, and set aside.

[0041] 2~7) with embodiment 1.

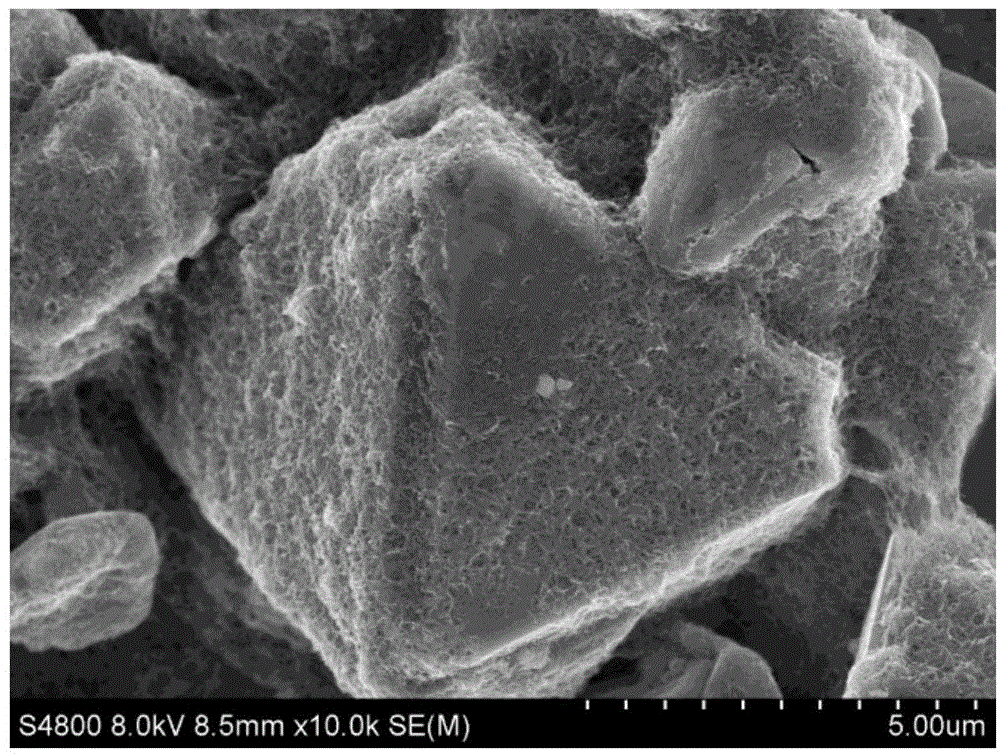

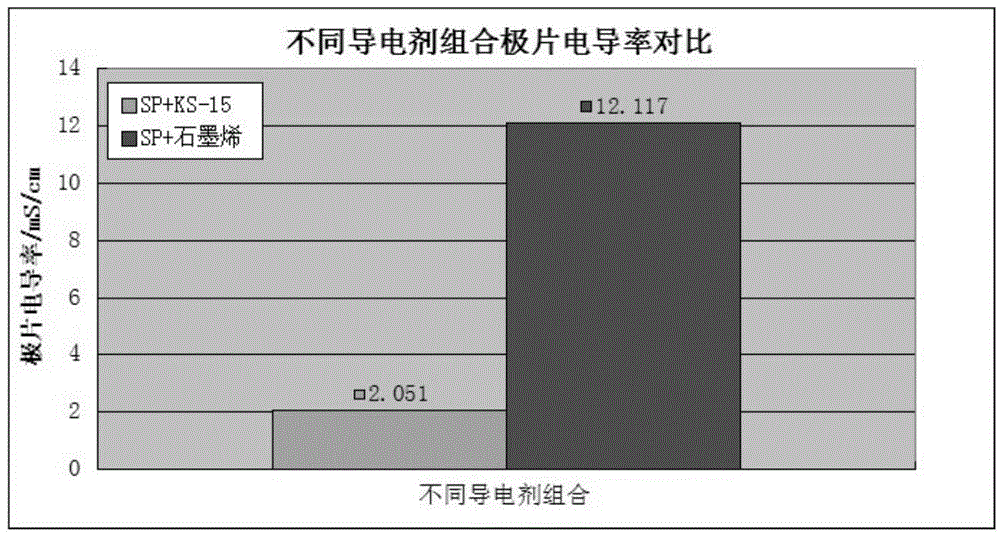

[0042] 8) Take a sample of the cut positive pole piece for SEM scanning test and electronic conductivity test, see figure 2 .

[0043] 9) With embodiment 1.

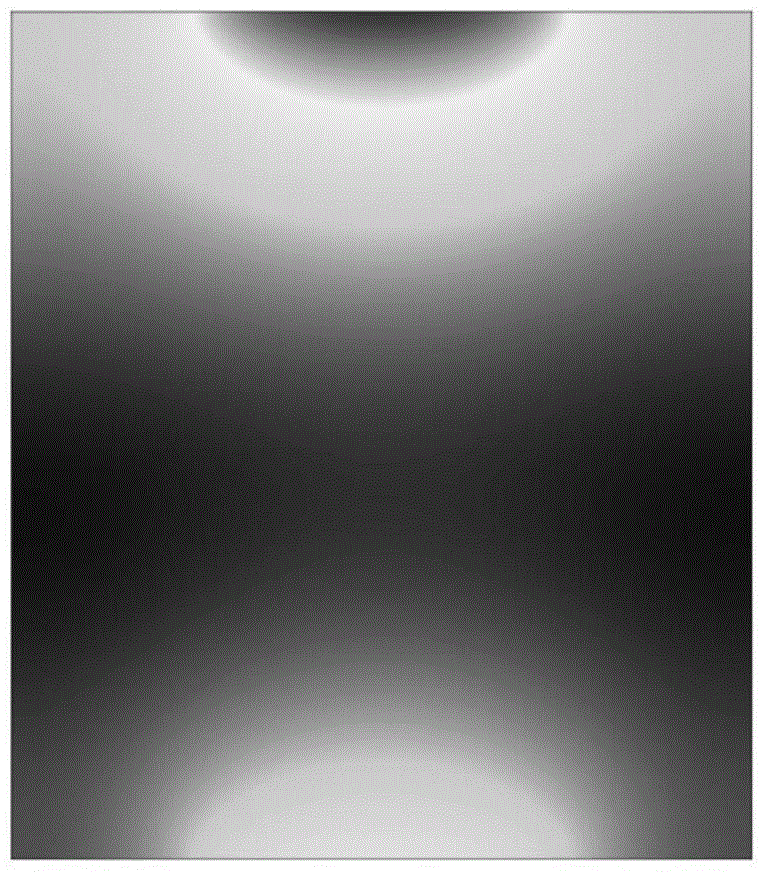

[0044] 10) In order to prove the improvement of thermal conductivity, a thermal imaging test was carried out on the complete battery, as shown in Figure 3. At the same time, an electrochemical high-temperature cycle performance test was also carried out to prove that the addition of the thermal conductivity material improved the cycle life.

[0045] pass figure 2 It can be seen that after adding graphene, the conductivity is greatly improved compared with the common positive electrode sheet without adding the same ratio, which can reduce the ohmi...

Embodiment 3

[0048] 1) Weigh lithium manganate LiMn 2 o 4 915g, PVDF45g, 20g of conductive carbon black SP and conductive graphite KS15, 10g of graphene, 10g of carbon nanotubes (CNTS), put the weighed materials in a high-temperature vacuum oven at 100°C for one night and set aside.

[0049] 2~9) with embodiment 1.

[0050] 10) In order to prove the improvement of thermal conductivity, the complete battery was subjected to a thermal imaging test, and at the same time, an electrochemical high-temperature cycle performance test was also performed, see Figure 4 , to prove that the addition of the thermally conductive material improves the cycle life.

[0051] pass Figure 4 It can be seen that the charge-discharge cycle test of the lithium manganate battery at a rate of 55°C 1C, the cycle life of the battery with the addition of the thermal conductive agent combination (graphene and CNTS) is significantly better than that of the ordinary lithium manganate battery without addition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com