Method for evaluating fatigue life of aged reinforced concrete bridge

A reinforced concrete, fatigue life technology, applied in the direction of instruments, data processing applications, computer-aided design, etc., can solve problems such as difficult fatigue life evaluation, single standard, and difficulty in accurately detecting initial cracks, so as to achieve reasonable prediction methods and strong generalization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

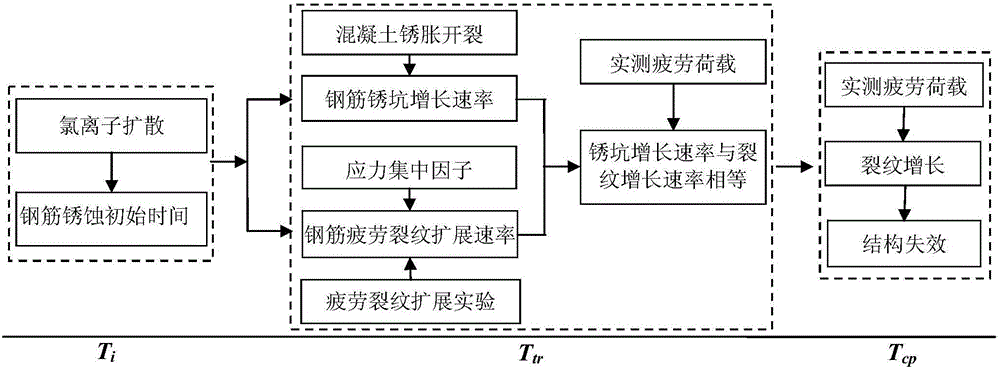

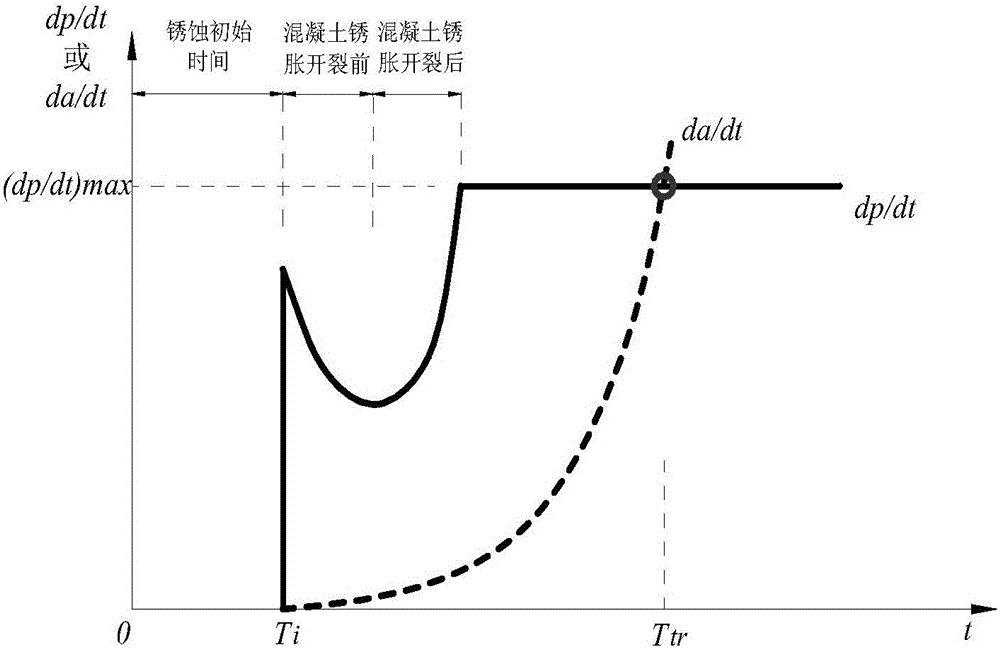

[0058] Such as figure 1 As shown, the life assessment can be divided into three stages: the initial time of steel corrosion T i , Steel rust pit growth control time T tr , steel fatigue crack growth control time T cp . The specific steps include:

[0059] (1) Determine the initial time of steel corrosion

[0060] Based on Fick’s second diffusion law, the time when the chloride ion concentration on the steel surface reaches the critical chloride ion concentration is taken as the initial corrosion time, and the initial corrosion time can be expressed as

[0061]

[0062] In the formula: T i is the initial time of steel corrosion; D c is the diffusion coefficient; C 0 is the chloride ion concentration on the concrete surface; erf is the error function; C is the thickness of the protective layer; C cr is the critical chloride ion concentration.

[0063] (2) Determine the corrosion rate of steel bars

[0064] After t years, the local corrosion depth of the reinforcemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com